Bacteria for degrading cellulose and microbial inoculum prepared by same

A technology for cellulose degrading bacteria and Aspergillus, applied in microorganisms, fungi, microorganism-based methods, etc., can solve the problems of severe reaction conditions, expensive equipment, environmental pollution, etc., and achieve simple fermentation conditions, convenient operation and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Examples of the present invention are described below.

[0017] The invention provides a cellulose-degrading bacterium, the strain YN1 of which is isolated from a soil sample collected from compost and identified as Aspergillus sp. The main morphological characteristics are: YN1 grows rapidly on Chase agar medium, the colony is flat and has radial grooves, and the texture is velvety; Spherical to radial; conidiophores occur in the stroma, near the apical capsule with light yellowish brown, smooth walls; sporulation structure single layer, conidia spherical, walls significantly rough, with spines.

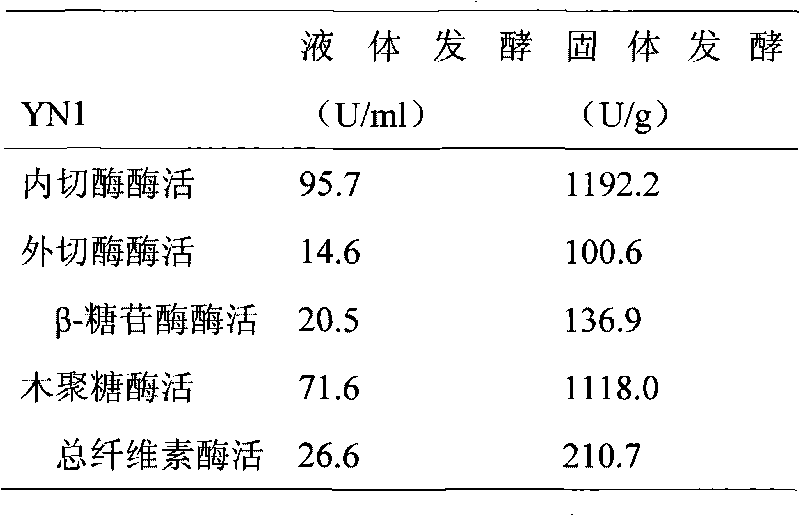

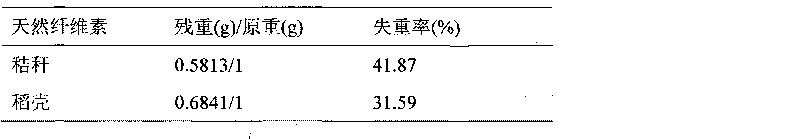

[0018] (1) Determination of liquid and solid fermentation enzyme activity of cellulose degrading bacteria YN1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com