Method for manufacturing thermosetting positive temperature coefficient thermistor and conductive adhesive therewith

A thermistor and positive temperature coefficient technology, which is applied to resistors with positive temperature coefficients, conductive adhesives, adhesives, etc., can solve the problem that the uniformity of resistance value is not within the scope of investigation, and the ideal low room temperature resistivity cannot be achieved. , affecting the normal operation of electrical equipment, etc., to achieve the effect of controllable cross-linking density, excellent reliability and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Note:

[0048] Thermosetting resin 1, rubber modified epoxy resin, CVC, grade RM-22, 70g solution (85% solid content, DMF solvent)

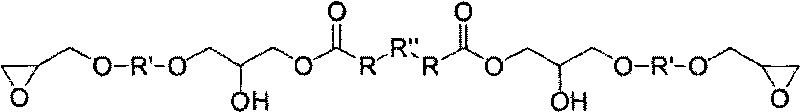

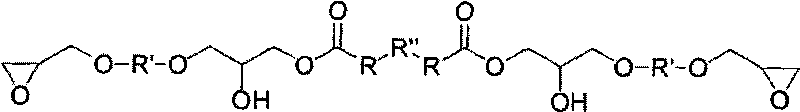

[0049] Curing agent 1, silicone modified self-crosslinking polyhydroxyl epoxy resin, Zhonglan Chenguang Chemical Research Institute, brand 670, 30g solution (75% solid content, DMF solvent)

[0050] Curing agent 2, polynonacetic anhydride, commercially available, 17.5g

[0051] Curing accelerator, 2-methylimidazole, commercially available

[0052] Conductive filler, nickel powder, INCO, grade 210

[0053] Inorganic filler, SiO 2 , Hangzhou Wanjing New Material Co., Ltd., brand VK-SP30

[0054] Auxiliary, coupling agent, Dow, 6030

[0055] Solvent, DMF, acetone, commercially available

[0056] Put the thermosetting resin and curing agent in the above formula into a mixer filled with solvent and dissolve for 60 minutes at room temperature. After the dissolution is complete, turn on the agitator and stir at a speed of 200 rpm for...

Embodiment 2

[0058] The preparation of the prepreg is the same as in Example 1, the first period of hot pressing is set to 75 minutes, and the subsequent process is the same as in Example 1.

Embodiment 3

[0060] The preparation of the prepreg is the same as in Example 1, the first period of hot pressing is set to 50 minutes, and the subsequent process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com