Health-care food with effects of neutralizing effect of alcoholic drinks and protecting liver

A technology for health food and liver protection, applied in food preparation, food science, application, etc., can solve the problem that the efficacy of ordinary food is difficult to guarantee, and achieve the effect of maintaining energy supply and nerve activity, reducing sobering, and enhancing activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

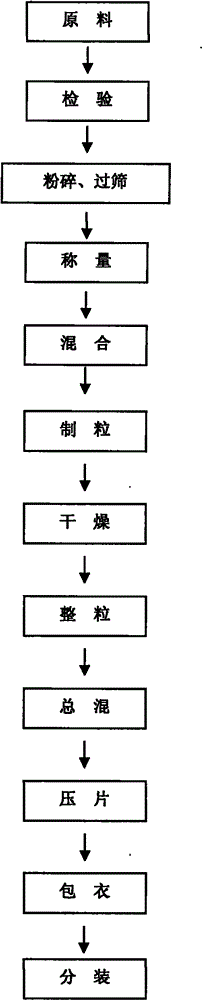

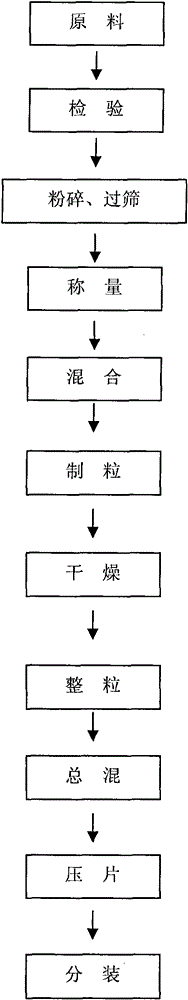

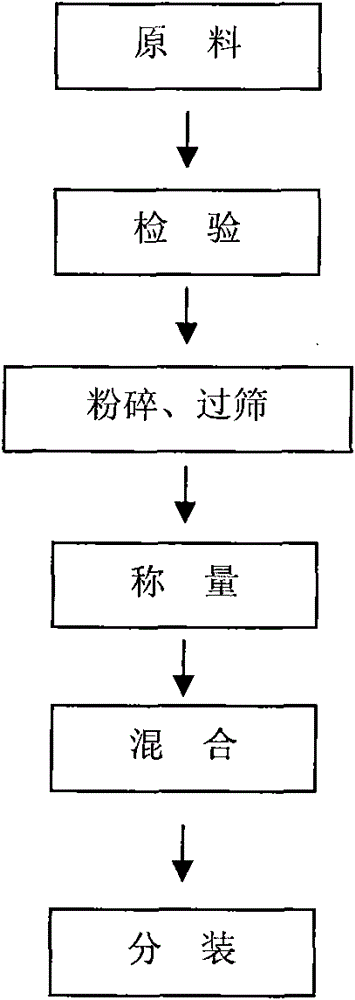

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: the preparation of corn oligopeptide powder

[0044] Take an appropriate amount of corn gluten powder raw material and add pure water at 40-65°C to make slurry, wherein the mass ratio of solids to pure water is 1:10; then heat to 70-95°C and maintain it for 20-40 minutes, and then at 3000rpm Centrifuge at a high speed; take the separated sediment and repeat the slurrying, heating and centrifuging operations; transfer the obtained sediment to the enzymatic hydrolysis tank after emulsification, adjust the temperature of the enzymatic hydrolysis tank to 40-60°C, and adjust the pH value to 8.0-9.0, then add Bacillus licheniformis protease and papain for enzymolysis for 2-4 hours, wherein the added amount of Bacillus licheniformis protease is 0.01%-0.10% of the substrate content, and the added amount of papain is 0.10% of the substrate content %-0.25%, stirring continuously during the enzymolysis; after the end of the enzymolysis, use a high-temperature trans...

Embodiment 2

[0045] Embodiment two: the preparation of corn oligopeptide powder

[0046] Take an appropriate amount of corn gluten powder raw material and add deionized water to adjust the slurry, the concentration is 5%-10%; measure the pH value of the slurry, and adjust the pH value to 9.0-11.0 with 20%-40% sodium hydroxide solution; Heat to 90-105°C, soak for 1-3 hours; then cool down to 45-65°C, add Bacillus licheniformis protease for 3-6 hours under the condition of pH 9.0-11.0; continue to cool down the obtained enzymatic solution to 30-45°C, and adjust its pH value to 7.0-8.5 with 20%-40% hydrochloric acid solution, add Bacillus subtilis protease for 2-5 hours; The obtained enzymolysis solution was deenzyme treated at -125°C; the enzymolysis solution after deenzyme treatment was centrifuged, and the obtained clear liquid was filtered through a membrane filter device to separate into small molecular peptide liquid and retentate; The concentrator concentrates the peptide solution to ...

Embodiment 3

[0047] Example 3: Preparation of Hovenia dulcis Fructus Extract

[0048] Take an appropriate amount of decoction pieces of Hovenia dulcis, spray them with water to make them fully moist, and set aside; put the decoction pieces into the extraction tank, add water and decoct three times, the amount of water added for the first time is 15 times the amount of medicinal materials, decoct for 2 hours and then filter , the amount of water added for the second time is 10 times the amount of medicinal materials, filtered after decocting for 1.5 hours, the amount of water added for the third time is 10 times the amount of medicinal materials, filtered after decocting for 1 hour; the filtrates obtained three times are combined, and the supernatant is extracted The liquid enters the vacuum concentrator, concentrates under reduced pressure under reduced pressure at 60-80°C and -0.01--0.06Mpa to a relative density of 1.05-1.08 (at 80°C), and filters through 350 mesh; take the extract obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com