Method for safe adsorption and enrichment of gas with low concentration

A low-concentration gas and safe technology, applied in the field of pressure swing adsorption gas separation, can solve problems such as gas explosion limit, and achieve the effect of improving quality, flexible and convenient operation, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

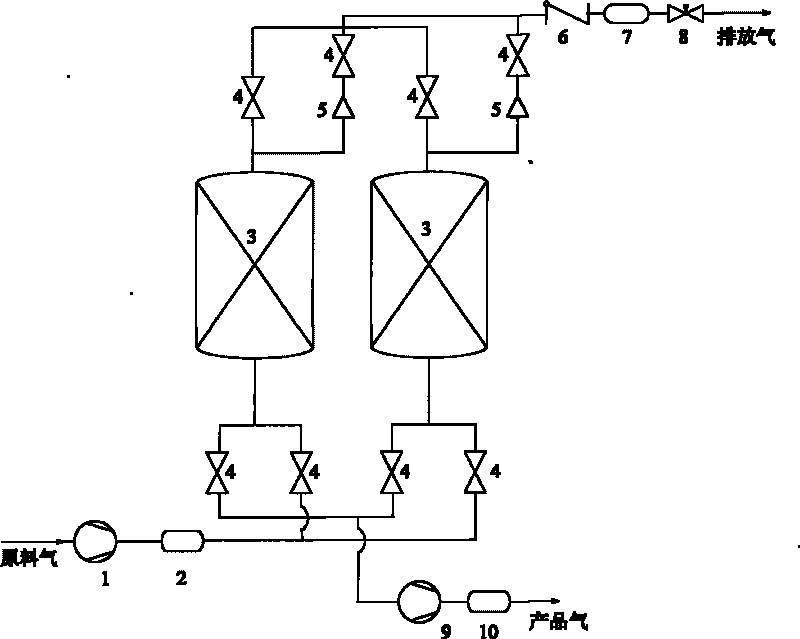

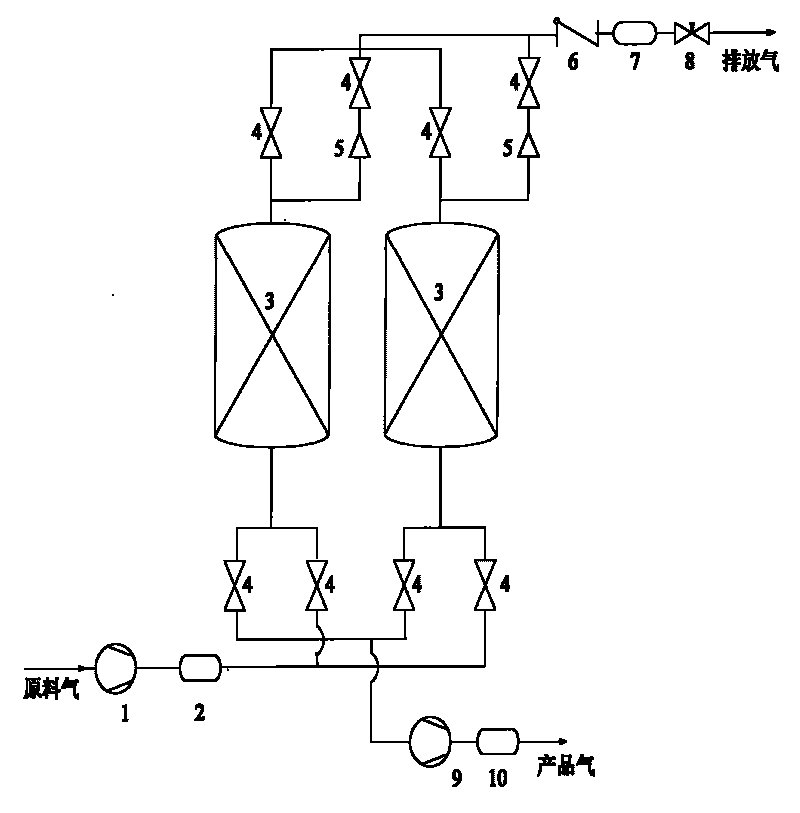

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] An embodiment of the method for safe adsorption and enrichment of low-concentration gas of the present invention is as follows: figure 2 As shown, raw gas is compressed by compressor 1 and flows into adsorption tower 3 through intake buffer tank 2 and control valve 4 . After the adsorbent in the adsorption tower 3 absorbs methane and oxygen in the raw gas, the exhaust gas flows out from the exhaust end of the adsorption tower, and flows through the throttle 5, the control valve 4, the one-way valve 6, and the exhaust buffer tank 7 in sequence. , Flow regulating valve 8 and then discharged into the atmosphere. After the adsorption is finished, the product gas is extracted from the adsorption tower 3 by the vacuum pump 9 .

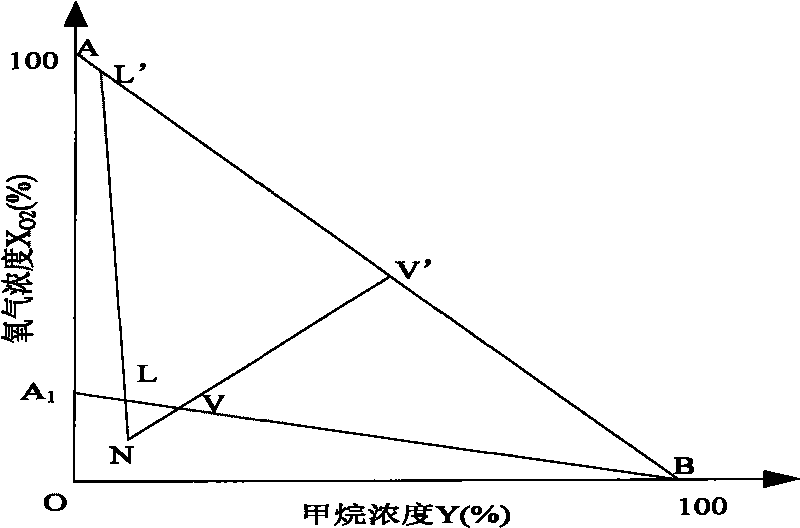

[0018] The low-concentration methane gas components in this embodiment are as follows: the volume fraction of methane is 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com