High-stability fluid catalyst for producing acrylonitrile

A fluidized bed catalyst, high stability technology, applied in the direction of physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, bulk chemical production, etc., can solve the conditions of low reaction pressure and low operating load and other problems, to achieve the effect of promoting the conversion of propylene, good technical effects, and reducing the by-products of deep oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] 1.6 grams of sodium hydroxide and 4.1 grams of potassium hydroxide and 11 grams of water were added and dissolved after heating to obtain material (A); 850.0 grams of ammonium molybdate was dissolved in 800 grams of hot water at 60 to 90°C to obtain material (B); Mix 157.5 grams of bismuth nitrate, 286.8 grams of manganese nitrate, 418.6 grams of barium nitrate, 594.5 grams of nickel nitrate, and 330.4 grams of ferric nitrate, add 340 grams of water, heat and dissolve as material (C), weigh 26.6 grams of praseodymium nitrate and 23.9 grams of oxide Germanium, add 15 grams of water, obtain material (D).

[0047] Mix material (A) with 2475 grams of silica sol with a weight concentration of 40%, add materials (B), (C) and (D) in turn under stirring, and obtain a slurry after thorough stirring, and prepare The slurry is carried out microsphere molding in the spray drier, and finally inner diameter is 89 millimeters, and length is 1700 millimeters ( 89 * 1700 mm) in a rota...

Embodiment 2~6 and comparative example 1~4

[0050] Catalysts with different compositions in the following table were prepared by the same method as in Example 1, and the ammoxidation of propylene to acrylonitrile was carried out with the prepared catalyst under the following reaction conditions. The results are shown in Table 1.

[0051] The reaction conditions of above-mentioned embodiment and comparative example are:

[0052] 38 mm fluidized bed reactor

[0053] Reaction temperature 440°C

[0054] Reaction pressure 0.14MPa

[0055] Catalyst loading 400 grams

[0056] Catalyst propylene loading (WWH) 0.085 hours -1

[0057] Raw material ratio (mole) C 3 = / NH 3 / air=1 / 1.2 / 9.8

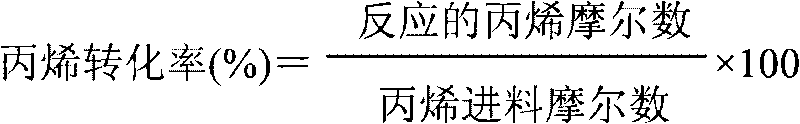

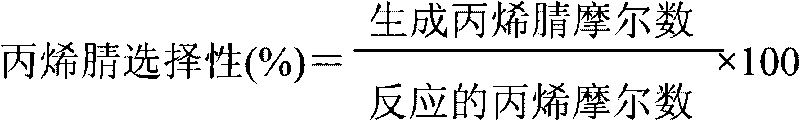

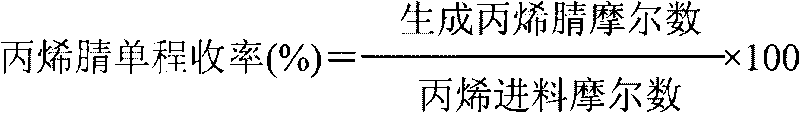

[0058] The reaction results were calculated at 4 hours, 400 hours, 800 hours and 1200 hours after the start of the reaction.

[0059] Table 1

[0060]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com