Method for preparing rutile titania nanoparticles

A technology of nano-titanium dioxide and rutile phase, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of complicated process, environmental pollution, and difficulty in reducing production costs, and achieve simple and easy process, convenient parameter control and long growth cycle short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

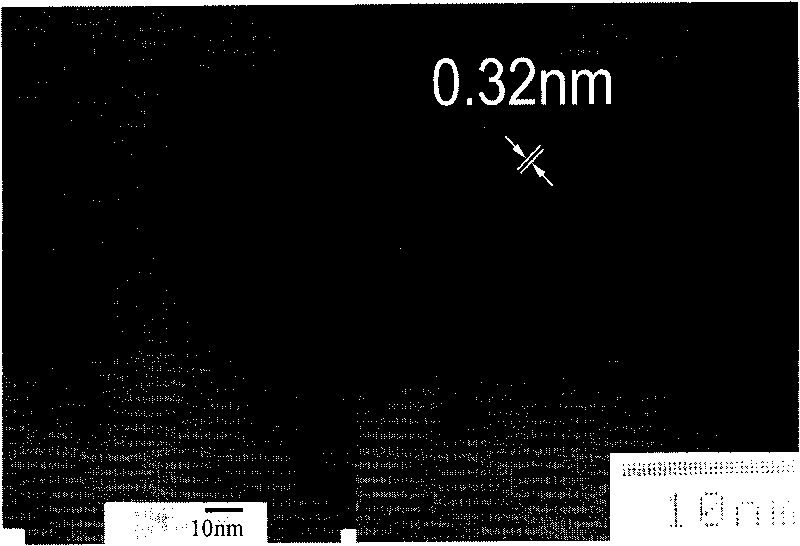

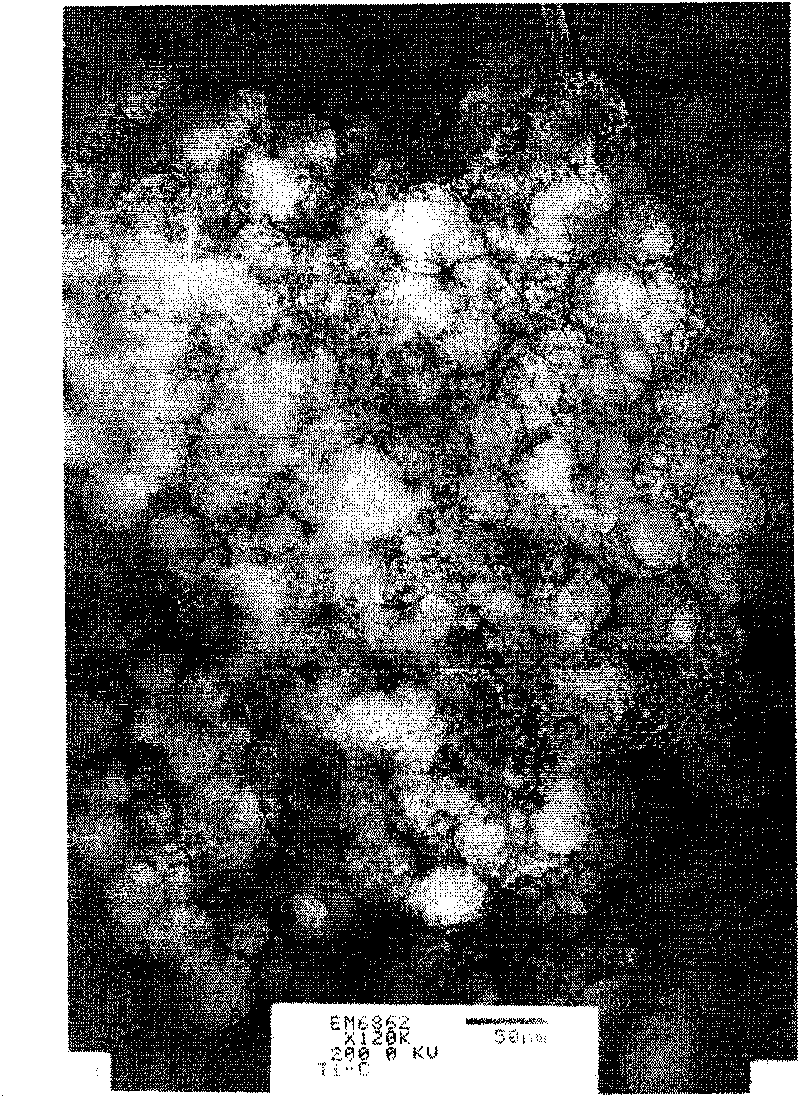

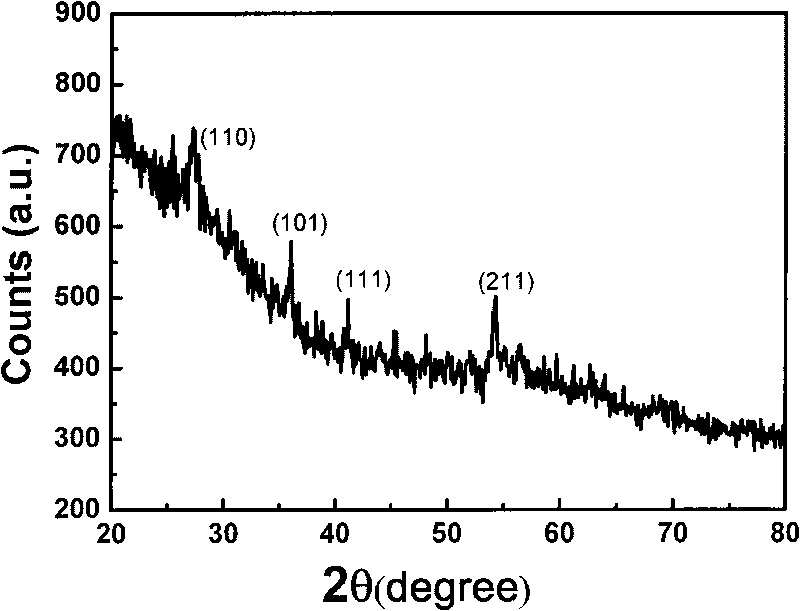

Embodiment 1

[0020] The specific steps of preparation are as follows: step 1, first mix polyvinylpyrrolidone with water to obtain a polyvinylpyrrolidone solution with a concentration of 0.01M, and then place the titanium sheet in the stirred polyvinylpyrrolidone solution; wherein, the polyvinylpyrrolidone The weight average molecular weight is 2000, the water is deionized water, and the purity of the titanium sheet is 99.9%. Step 2, irradiate the titanium sheet with a laser with a wavelength of 1064nm, a power of 70mJ / pulse, a frequency of 5Hz, and a pulse width of 15ns for 40 minutes to obtain a titanium dioxide colloid; wherein the laser emitting a laser with a wavelength of 1064nm is a Nd:YAG solid-state laser, and the laser The spot diameter is 1mm. In step 3, the titanium dioxide colloid was subjected to centrifugation, washing and drying; wherein, the rotating speed of the centrifugation was 13000r / min, the washing was washed twice with deionized water, and the drying was kept at 30°...

Embodiment 2

[0022] The specific steps of preparation are: step 1, first mix polyvinylpyrrolidone with water to obtain a polyvinylpyrrolidone solution with a concentration of 0.05M, and then place the titanium sheet in the stirred polyvinylpyrrolidone solution; wherein, the polyvinylpyrrolidone The weight average molecular weight is 10000, the water is distilled water, and the purity of the titanium sheet is 99.99%. Step 2, irradiate the titanium sheet with a laser with a wavelength of 1064nm, a power of 85mJ / pulse, a frequency of 8Hz, and a pulse width of 13ns for 35 minutes to obtain a titanium dioxide colloid; wherein the laser emitting a laser with a wavelength of 1064nm is a Nd:YAG solid-state laser, and the laser The spot diameter is 1.3mm. In step 3, the titanium dioxide colloid was subjected to centrifugation, washing and drying; wherein, the rotational speed during centrifugation was 13500 r / min, the washing was three times with distilled water, and the drying treatment was heat p...

Embodiment 3

[0024]The specific steps of preparation are: step 1, first mix polyvinylpyrrolidone with water to obtain a polyvinylpyrrolidone solution with a concentration of 0.1M, and then place the titanium sheet in the stirred polyvinylpyrrolidone solution; wherein, the polyvinylpyrrolidone The weight average molecular weight is 20000, the water is deionized water, and the purity of the titanium sheet is 99.9%. Step 2, irradiate the titanium sheet with a laser with a wavelength of 1064nm, a power of 100mJ / pulse, a frequency of 10Hz, and a pulse width of 10ns for 30 minutes to obtain a titanium dioxide colloid; wherein the laser emitting a laser with a wavelength of 1064nm is a Nd:YAG solid-state laser, and the laser The spot diameter is 1.5mm. In step 3, the titanium dioxide colloid was subjected to centrifugation, washing and drying; wherein, the rotational speed during centrifugation was 14000 r / min, the washing was washed twice with absolute ethanol, and the drying treatment was kept ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com