Compact 10 B boron carbide-rich ceramics and preparation thereof

The technology of boron carbide ceramics and boron carbide powder is applied in the field of dense 10B-rich boron carbide ceramics and its preparation. Density, high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

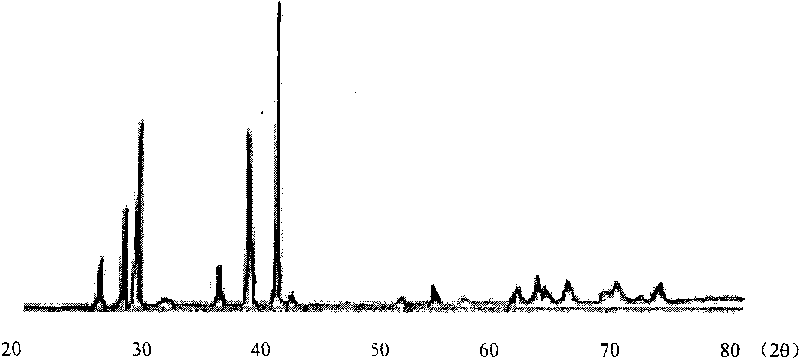

Image

Examples

Embodiment 1

[0041] Example 1: Dense Rich 10 The raw material components of B boron carbide ceramics are as follows: 10 B: 90 parts of boron carbide powder, 3 parts of europium oxide, 2 parts of samarium oxide, 1 part of zirconia, and 4 parts of aluminum oxide, all of which are parts by mass. The rich B 10 The abundance of boron carbide powder is 90%, d 50 2.5 μm.

[0042] The preparation method steps are as follows:

[0043] 1. According to the above parts by weight, the 10 B boron carbide powder, europium oxide, samarium oxide, zirconia and alumina powder use absolute ethanol as the medium, the lining of the ball mill tank and the ball mill medium are both 95 porcelain, ball mill and mix for 30 minutes, dry under vacuum conditions, and prepare the mixture powder.

[0044] 2. Add the above-mentioned mixed powder into a rubber mold, and form it with a cold isostatic press, with a forming pressure of 300 MPa.

[0045] 3. Dry the molded green body above, put it into a sintering furnac...

Embodiment 2

[0047] Embodiment 2: as described in embodiment 1, the difference is rich in B 10 The abundance of boron carbide powder is 68%. product 10 B abundance is 54%.

Embodiment 3

[0048] Example 3: Dense Rich 10 The raw material components of B boron carbide ceramics are as follows: 10 B: 86 parts of boron carbide powder, 3 parts of europium oxide, 2 parts of samarium oxide, 3 parts of gadolinium oxide, and 4 parts of aluminum oxide, all of which are parts by mass. Said rich 10 The abundance of B boron carbide powder is 68%, d 50 2.5 μm.

[0049] The preparation method steps are as follows:

[0050] 1. According to the above parts by mass, the 10 B boron carbide powder, europium oxide, samarium oxide, gadolinium oxide and alumina powder use absolute ethanol as the medium, the lining of the ball mill tank and the ball milling medium are both 95 porcelain, the ball mill is mixed for 30 minutes, and dried under vacuum conditions to prepare the mixture powder.

[0051] 2. Gel injection molding

[0052] Add the above mixed powder into the mixed solution of monomer acrylamide (AM), crosslinking agent N, N'-methylenebisacrylamide and deionized water, di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com