Method for preparing nano magnetic polymer composite microspheres

A composite microsphere and nanomagnetic technology, which is used in magnetic objects, magnetic materials, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

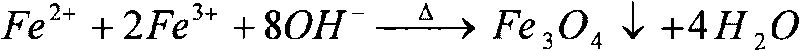

[0044] 1) Hydrophilic ultrafine Fe 3 o 4 Preparation of particle dispersion

[0045] Preparation of Fe by Chemical Co-precipitation 3 o 4 The components and parts contained in the particles are:

[0046] FeCl 3 ·6H 2 O 54.04g

[0047] FeCl 2 4H 2 O 19.88g

[0048] Deionized water 1200ml

[0049] Oleic acid 20g

[0050] 25% ammonia water 150ml

[0051] The preparation process is: FeCl 3 ·6H 2 O, FeCl 2 4H 2 Dissolve O in 600ml of deionized water, and add to 2L reactor after dissolving; nitrogen gas is passed under stirring condition, and oleic acid is added; after stirring for 5-10 minutes, 25% ammonia water is added dropwise at room temperature; keep at room temperature for 1 hour, and heat up to 90°C , keep stirring at 90°C for 1 hour; cool down and discharge.

[0052] 2) For the Fe obtained in 1) 3 o 4 Acidification treatment of particle dispersion to prepare hydrophobic ultrafine Fe 3 o 4 Particles, which contain components and parts are:

[0053] Hydr...

Embodiment 2

[0067] 1) Hydrophilic ultrafine Fe 3 o 4 Preparation of particle dispersion

[0068] Preparation of Fe by Chemical Co-precipitation 3 o 4 The components and parts contained in the particles are:

[0069] FeCl 3 ·6H 2 O 54.04g

[0070] FeCl 2 4H 2 O 19.88g

[0071] Deionized water 1200ml

[0072] Oleic acid 20g

[0073] 25% ammonia water 150ml

[0074] The preparation process is: FeCl 3 ·6H 2 O, FeCl 2 4H 2 Dissolve O in 600ml of deionized water, and add to 2L reactor after dissolving; nitrogen gas is passed under stirring condition, and oleic acid is added; after stirring for 5-10 minutes, 25% ammonia water is added dropwise at room temperature; keep at room temperature for 1 hour, and heat up to 90°C , keep stirring at 90°C for 1 hour; cool down and discharge.

[0075] 2) For the Fe obtained in 1) 3 o 4 Acidification treatment of particle dispersion to prepare hydrophobic ultrafine Fe 3 o 4 Particles, which contain components and parts are:

[0076] Hydr...

Embodiment 3

[0090] 1) Hydrophilic ultrafine Fe 3 o 4 Preparation of particle dispersion

[0091] Preparation of Fe by Chemical Co-precipitation 3 o 4 The components and parts contained in the particles are:

[0092] FeCl 3 ·6H 2 O 54.04g

[0093] FeCl 2 4H 2 O 19.88g

[0094] Deionized water 1200ml

[0095] Oleic acid 20g

[0096] 25% ammonia water 150ml

[0097] The preparation process is: FeCl 3 ·6H 2 O, FeCl 2 4H 2 Dissolve O in 600ml of deionized water, and add to 2L reactor after dissolving; nitrogen gas is passed under stirring condition, and oleic acid is added; after stirring for 5-10 minutes, 25% ammonia water is added dropwise at room temperature; keep at room temperature for 1 hour, and heat up to 90°C , keep stirring at 90°C for 1 hour; cool down and discharge.

[0098] 2) For the Fe obtained in 1) 3 o 4 Acidification treatment of particle dispersion to prepare hydrophobic ultrafine Fe 3 o 4 Particles, which contain components and parts are:

[0099] Hydrop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com