Powdered epoxy resin toughener and preparation method thereof

A technology of powder epoxy resin and epoxy resin, which is applied in the field of toughening agent, can solve the problems of less research on toughening, and achieve the effect of cheap raw materials, easy control, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 72 mL (0.5 mol) of n-butyl acrylate (nBA), 6.82 mL (0.05 mol) of glycidyl methacrylate (GMA), 120 mL of solvent (N, N-dimethylformamide), initiator (azobis Isobutyronitrile) 0.35g adds and installs agitator, reflux condenser and N 2 In the 500mL four-neck bottle of the gas protection device, nBA and GMA were added according to the ratio of the experimental design (nBA / GMA molar ratio 10 / 1). React at a temperature of about 70°C for 5-6 hours.

[0021] The product was precipitated with deionized water, washed, dissolved, precipitated, and washed again, and finally dried in a vacuum oven (40° C.) for 24 hours to obtain pure polymer P(nBA-GMA).

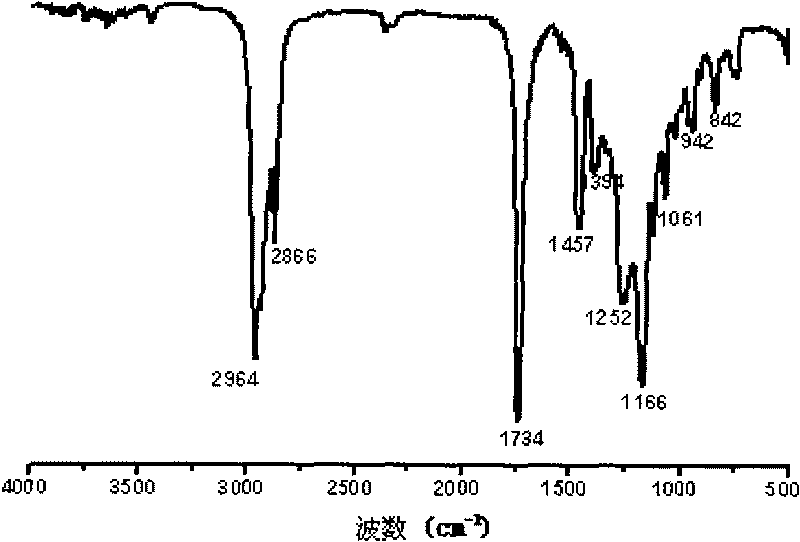

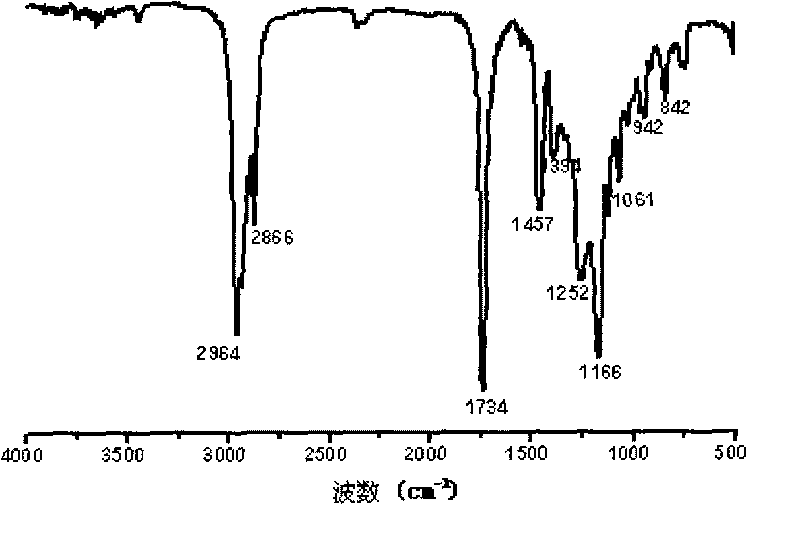

[0022] The structure of the product was characterized with an infrared spectrometer, and the results are shown in figure 1 , 1730cm on the spectrum -1 Nearby is the absorption peak of carbonyl, 1149cm -1 It is the asymmetric absorption peak of C-O-C in the ester group. The characteristic absorption peak of the epoxy functional...

Embodiment 2

[0024] The solid epoxy resin and the synthesized toughening agent are physically blended by heating and melting according to different proportioning systems (the mass ratio of toughening agent to epoxy resin is 0 / 100-25 / 100), and a phenolic curing agent is added (the mass ratio is 20% of the epoxy resin), extruded and cooled on an extruder, and finally pulverized to obtain a blending system of a toughening agent, an epoxy resin and a curing agent.

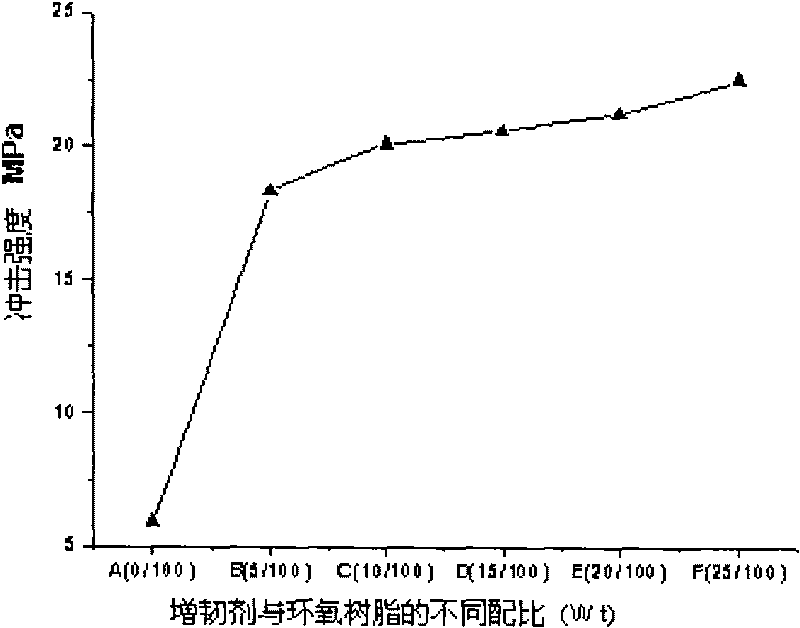

[0025] The obtained blend system powder is pressed on a hot press, and finally processed into test strips for mechanical property testing. figure 2 is the impact performance curve of epoxy resin modified with different proportions of toughener, figure 2 It shows that the addition of toughening agent can improve the impact toughness of epoxy resin, and the impact strength increases with the increase of toughening agent. When the mass ratio of toughening agent to epoxy resin is 5 / 100, the toughness of the spline increases signific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com