Method for manufacturing polyphenylene sulfide meltblown fiber products

A technology of meltblown fibers and polyphenylene sulfide, which is applied in the field of manufacturing fiber-grade polyphenylene sulfide meltblown fibers, can solve the problems of unclear mechanical properties, no polyphenylene sulfide meltblown fibers, and insufficient mechanical strength of fibers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

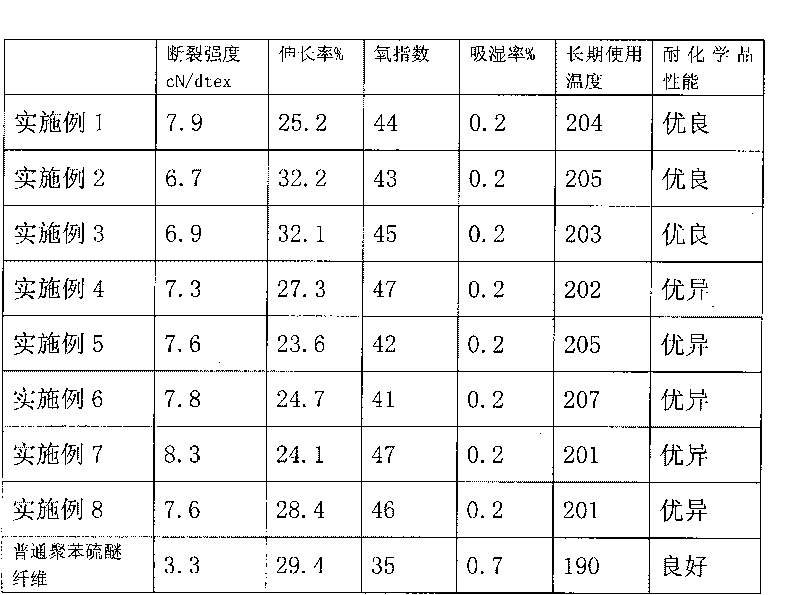

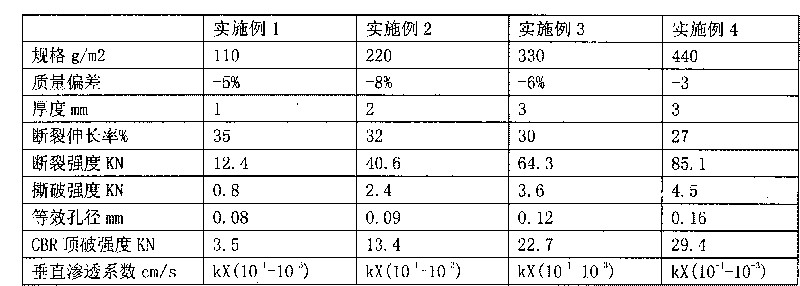

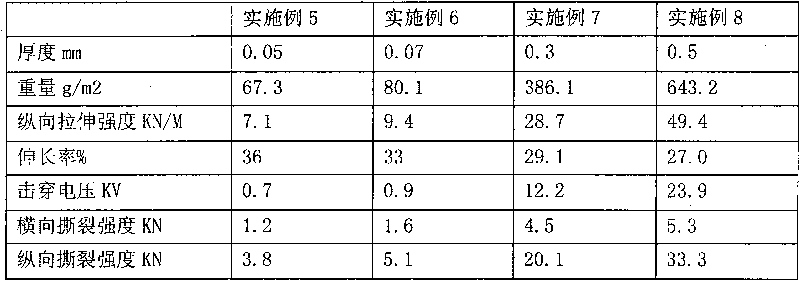

Examples

Embodiment 1

[0020] Polyphenylene sulfide melt-blown fiber non-woven fabric, the process is: fiber-grade polyphenylene sulfide resin premixing treatment - vacuuming, twin-screw extruder melting - melt metering pump - forced filtration, spinneret assembly ——Silk melt blown——High pressure nitrogen gas cutting——Fiber non-woven fabric. The following process conditions were used.

[0021] With oligomer, cyclic compound, reaction by-product, reaction auxiliary agent impurity content is no more than 0.1% in resin, weight average molecular weight is 99.5kg of fiber grade polyphenylene sulfide resin of 50,000 and its polydispersity coefficient is 1.88, Add 0.5kg (0.5%) antistatic agent antistatic agent lauryl amidopropyltrimethylammonium methyl sulfate into fiber-grade polyphenylene sulfide resin, stir evenly through a high-speed mixer, and then extrude through a twin-screw extruder, The melt-blown fiber resin chips are obtained, and then the resin is dried at 110-160° C. for 2-8 hours; the drying...

Embodiment 2

[0026] Weight-average molecular weight is 99.4kg at 60,000 and its polydispersity coefficient is the fiber grade polyphenylene sulfide resin of 1.9, with 0.6kg (0.6%) antistatic agent antistatic agent N, N-two (2-hydroxyethyl)- N-(3'-dodecyloxy-2'-hydroxypropyl)methylammonium methyl sulfate was added to fiber grade polyphenylene sulfide resin. All the other process control conditions are identical with example 1.

[0027] The frequency of the frequency conversion motor of the metering pump is 10 Hz, the pressure of the spinneret assembly is 15.0Mpa. The spinneret aperture is 0.3mm, the temperature of the spinning box is 335°C, and the spinning temperature is 335°C; the temperature of 40Mpa high-pressure nitrogen is 120°C, and the angle is 30° , the speed is 880m / s, the temperature of the cooling nitrogen is kept at 8°C, and the fiber-grade polyphenylene sulfide resin is melt-blown by using the above process conditions to obtain the polyphenylene sulfide melt-blown fiber; then ...

Embodiment 3

[0029] Weight-average molecular weight is 98.5kg at 50,000 and its polydispersity coefficient is the fiber grade polyphenylene sulfide resin of 1.86, and 1.5kg (1.5%) antistatic agent trihydroxyethyl methyl quaternary ammonium methyl sulfate methyl ester salt is added fiber grade polyphenylene sulfide resin In phenylene sulfide resin. All the other processing conditions are identical with example 1

[0030] The frequency of the frequency conversion motor of the metering pump is 22 Hz, the pressure of the spinneret assembly is 28.0Mpa, the spinneret aperture is 0.5mm, the temperature of the spinning box is 315°C, and the spinning temperature is 315°C; the temperature of the 33Mpa high-pressure nitrogen is 110°C, and the angle is 25° , the speed is 871m / s, the temperature of cooling nitrogen is kept at 8°C, and the fiber-grade polyphenylene sulfide resin is melt-blown by using the above process conditions to obtain polyphenylene sulfide melt-blown fibers; The phenylene sulfide m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com