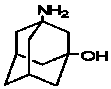

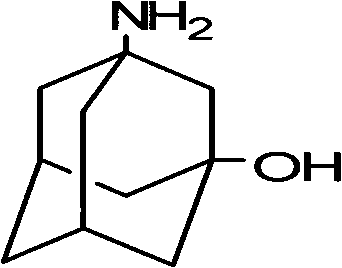

Method for synthesizing 3-amino-1-adamantanol

A technology of adamantanol and a synthesis method, which is applied to the preparation of amino hydroxy compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of difficult industrialization, low safety factor of sodium azide, etc., and achieves simple and easy operation. , The effect of easy availability of raw materials and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take 100mL of dried liquid bromine (dried with concentrated sulfuric acid) and 60g of anhydrous aluminum trichloride in a 250mL three-necked flask, set up a mechanical stirring and reflux condensation device (use saturated sodium bicarbonate solution for tail gas absorption), and place in anhydrous In the state, the temperature was lowered to -20°C, and 30 g of dry adamantanecarboxylic acid powder was quantitatively added within 4 hours under stirring, and reacted at -20°C for 48 hours, and then reacted at 20°C for 5 hours to stop the reaction.

[0024] Pour the reacted product into a large beaker containing 500g of crushed ice and 300mL of dichloromethane to cool, add sodium bisulfite solution under stirring to remove excess liquid bromine, extract and separate the organic phase, and then add 250mL of 1mol / L Stir the sodium hydroxide solution in the organic phase, extract and separate the lye layer, then acidify it with 2mol / L hydrochloric acid until it becomes acidic, ...

Embodiment 2

[0030] Take 50mL of dried liquid bromine (dried with concentrated sulfuric acid) and 10g of anhydrous aluminum chloride in a 150mL three-necked flask, set up a mechanical stirring and reflux condensation device (use saturated sodium bicarbonate solution for tail gas absorption), and place in anhydrous state Cool down to -10°C, slowly add dry 18g adamantanecarboxylic acid powder within 4 hours under stirring, react at -10°C for 50 hours, then react at 25°C for 5 hours, and stop the reaction.

[0031] Pour the obtained product into a large beaker containing crushed ice to cool, add sodium bisulfite solution under stirring to remove excess liquid bromine, then pour into 200mL dichloromethane solvent, extract and separate the organic phase, and then add 100mL1mol / L hydroxide Stir the sodium solution in the organic phase, extract and separate the lye layer, then acidify it with 2mol / L hydrochloric acid until it becomes acidic, let it stand still, precipitate out, filter and dry. Re...

Embodiment 3

[0037]Take 100mL of dried liquid bromine (dried with concentrated sulfuric acid) and 40g of anhydrous aluminum trichloride in a 250mL three-necked flask, set up a mechanical stirring and reflux condensation device (use saturated sodium bicarbonate solution for tail gas absorption), and place in anhydrous In the state, the temperature was lowered to 0°C, and 25g of dry adamantanecarboxylic acid powder was quantitatively added within 4 hours under stirring, and reacted at 0°C for 55 hours, then reacted at 30°C for 5 hours, and stopped the reaction.

[0038] Pour the reacted product into a large beaker containing 500g of crushed ice and 300mL of dichloromethane to cool, add sodium bisulfite solution under stirring to remove excess liquid bromine, extract and separate the organic phase, and then add 250mL of 1mol / L Stir the sodium hydroxide solution in the organic phase, extract and separate the lye layer, then acidify it with 2mol / L hydrochloric acid until it becomes acidic, let i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com