Treatment combined process for pig farm waste water with high nitrogen content

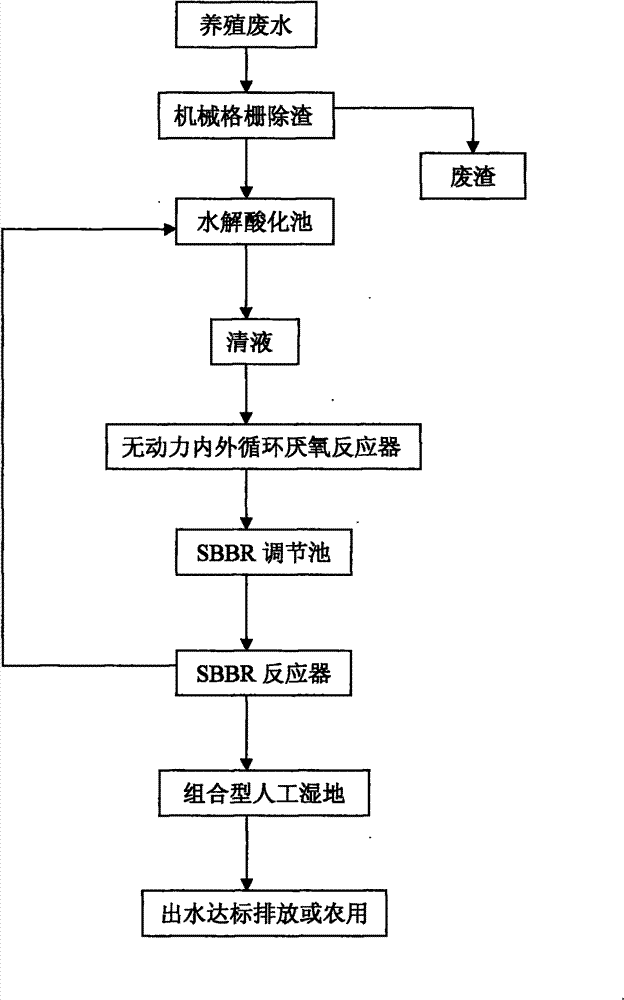

A combined process and pig farm wastewater technology, which is applied in the direction of animal husbandry wastewater treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the large changes in the quality and quantity of pig farm wastewater, the imbalance of nutrient elements, and the content of ammonia nitrogen High-level problems, to achieve the effect of improving processing capacity and stability, improving impact load resistance, and facilitating nitrification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

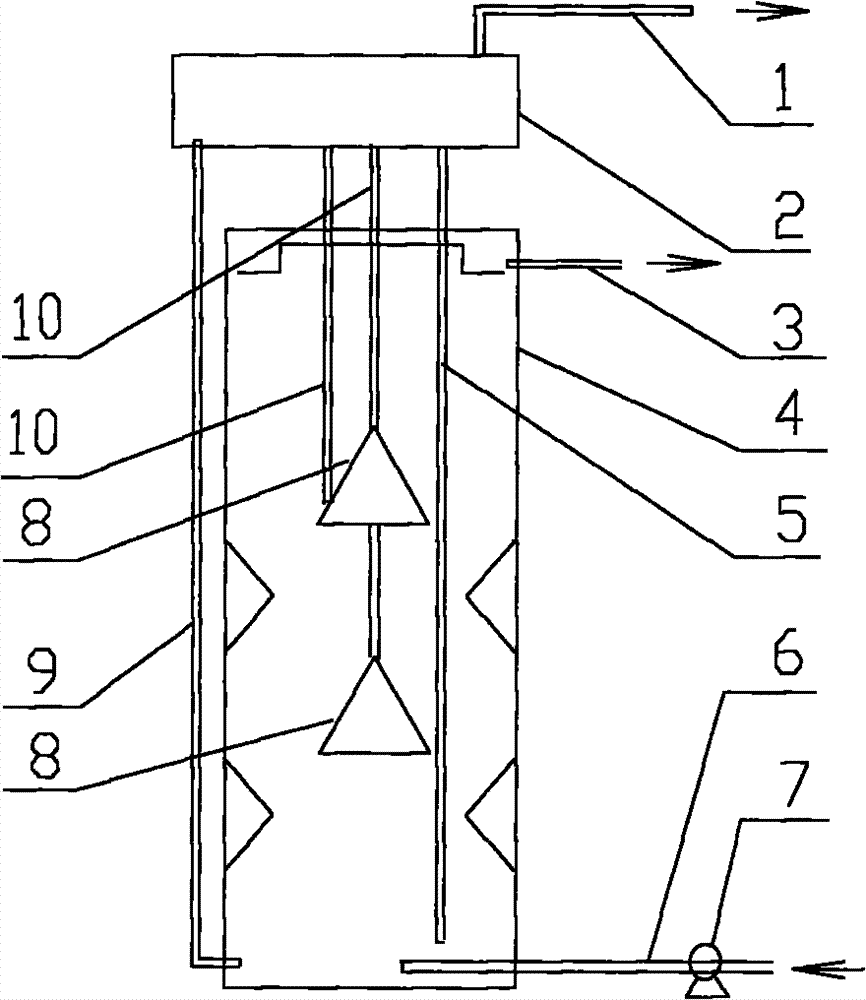

[0026] The embodiment of the present invention is implemented in a farm with ten thousand pigs. According to the combined process route of the present invention, the embodiment of the present invention has respectively built a mechanical grid slag removal tank, a hydrolysis acidification tank, an anaerobic reactor with no power internal and external circulation, and an SBBR adjustment tank. , SBBR treatment pool and constructed wetland.

[0027] The present embodiment pig farm waste water, daily treatment capacity is 150m 3 / d, waste water quality: COD 5000~10000mg / L, NH 4 + -N 400~1500mg / L, TP30~100mg / L. The waste water enters the hydrolytic acidification tank, and then enters the anaerobic reactor. The metabolic function of heterotrophic bacteria is used to decompose the refractory organic matter into biodegradable small molecular organic matter, and at the same time mineralize the organic nitrogen, and degrade and remove most of the easily biodegradable organic matter. ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com