Polyester composition and application thereof

A technology of composition and polyester, which is applied in the field of polyester composition for hot-pressed films, can solve the problems of high turbidity of products, poor dispersion of nanoparticles, and little contribution to crystallization performance, etc., and achieve good color tone and excellent crystallization performance , good low haze effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

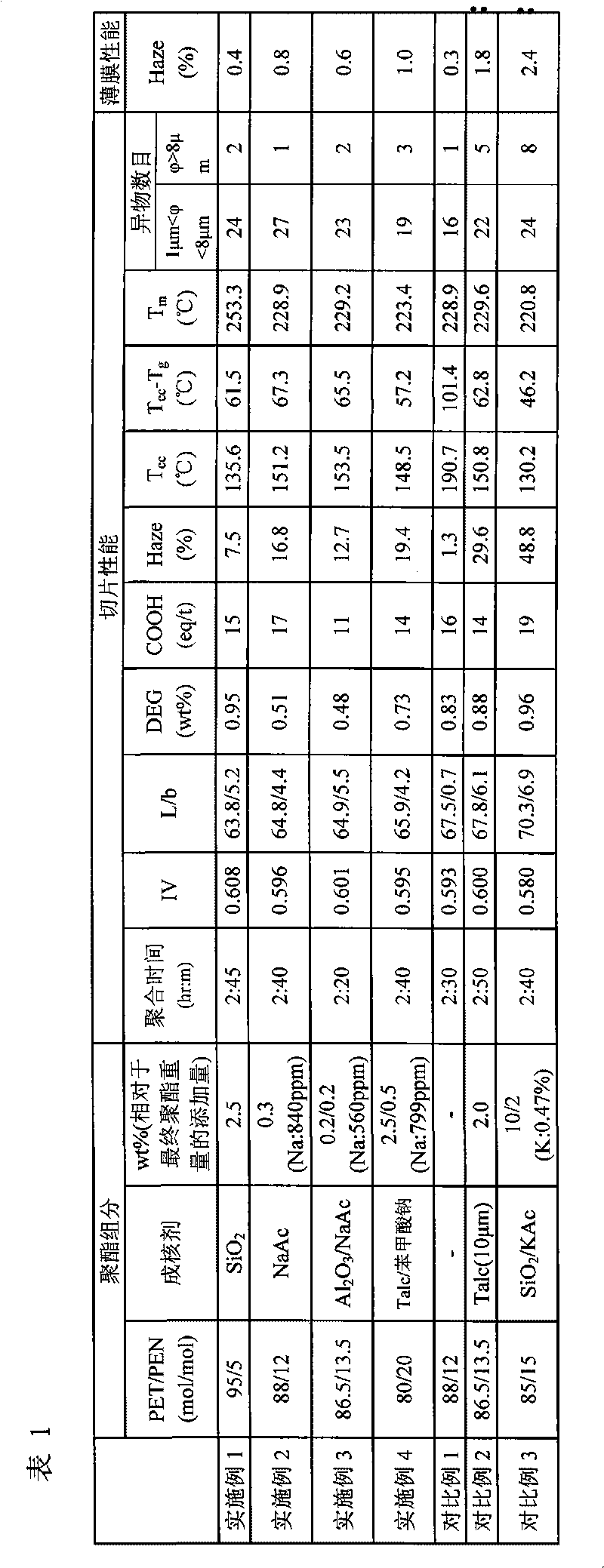

Examples

Embodiment 1

[0055] Acetate is added as a catalyst during the transesterification process, a phosphorus stabilizer and a nucleating agent are added after the transesterification reaction (EI reaction), and an antimony compound is added as a catalyst during the polycondensation process to obtain a polyester composition through polycondensation reaction.

[0056] The polyester is a PET-PEN copolymer obtained by transesterifying dimethyl terephthalate and dimethyl naphthalate with ethylene glycol.

[0057] The acetate catalyst used is magnesium acetate, lithium acetate. The antimony compound catalyst is antimony trioxide.

[0058] The nucleating agent is specifically nano-SiO 2 .

[0059] Concrete reaction process is as follows:

[0060] At a temperature of 160°C, 937.9 parts (weight) of dimethyl terephthalate (BASF) and 62.1 parts (weight) of dimethyl naphthalate (Japan Mitsubishi Gas Corporation) were mixed with 631 parts (weight) of ethyl Glycol (Yangzi Petrochemical, China) was transe...

Embodiment 2

[0063] At a temperature of 160° C., 862 parts (weight) of dimethyl terephthalate and 148 parts (weight) of dimethyl naphthalene dicarboxylate in 626 parts (weight) of ethylene glycol were subjected to an EI reaction, which was placed in the formulation Add 600ppm of magnesium acetate and 50ppm of lithium acetate as transesterification catalysts to a polymerization flask with a rectification tower, and react under normal pressure. When the temperature in the flask is 235°C and the temperature at the top of the rectification tower drops to 50°C, The above reaction is completed to obtain a small molecular polymer.

[0064] Add phosphorus stabilizer TEPA, the addition amount relative to final polyester weight is 500ppm, after 5 minutes, add nucleating agent sodium acetate NaAc (Jiangsu Jincheng Reagent Co., Ltd.), addition amount is 3 parts (weight). NaAc was dispersed in EG to form a 10wt% slurry, and then fed. with Sb as a polymerization catalyst 2 o 3 The compound addition a...

Embodiment 3

[0066] At a temperature of 160°C, 835.9 parts (weight) of dimethyl terephthalate and 164.1 parts (weight) of dimethyl naphthalene dicarboxylate were subjected to EI reaction in 617.7 parts (weight) of ethylene glycol, and added as a transesterification catalyst Magnesium acetate (600ppm relative to the weight of the final polyester) and lithium acetate (50ppm relative to the weight of the final polyester) were reacted under normal pressure. When the temperature in the flask was 235°C, rectification When the temperature at the top of the tower drops to 50° C., the above reaction is completed, and a polymer with small molecules is obtained.

[0067] Add phosphorus stabilizer TEPA, the addition amount relative to final polyester weight is 500ppm, after 5 minutes, add Al 2 o 3 (Degussa, Germany) and the composite nucleating agent of NaAc, Al 2 o 3 The particle size is 20 nm, the added amount is 2 parts by weight, and the added amount of NaAc is 2 parts by weight. The composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com