Method for synthesizing phosphorus-free corrosion-inhibition scale inhibitor for water treatment from natural products

A natural product, phosphorus-free corrosion inhibition technology, applied in water/sludge/sewage treatment, chemical instruments and methods, scale removal and water softening, etc., can solve a small amount of biodegradable, non-biodegradable, and decompose non-toxic substances and other problems, to achieve the effect of reducing reproduction, simple and easy control of scale inhibition treatment, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

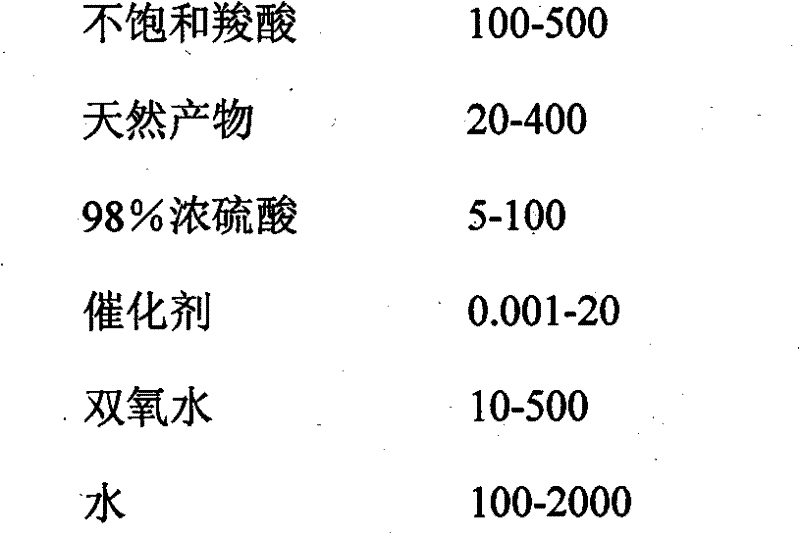

[0026] The natural product is grafted and modified with unsaturated carboxylic acid. The raw materials of the non-phosphorus corrosion and scale inhibitor are: unsaturated carboxylic acid, natural product, concentrated sulfuric acid, catalyst, hydrogen peroxide, water, etc. The parts by weight of each raw material are:

[0027] Unsaturated carboxylic acid 150

[0028] Natural Products 150

[0029] Concentrated sulfuric acid (98%) 20

[0030] Catalyst 10

[0032] water 1200

[0033] The unsaturated carboxylic acid is mainly maleic anhydride; the natural product is lignosulfonate, a product of papermaking waste residue, and can also be polysaccharides and their derivatives or humic acid, tannin, etc.; The catalyst is ammonium persulfate.

[0034] The specific preparation method is as follows: add 800 kg of water into the rinsed reactor, pump 20 kg of concentrated sulfuric acid into the reactor under stirring conditions, add 150 kg of maleic a...

Embodiment 2

[0036] The natural product is grafted and modified with unsaturated carboxylic acid. The raw materials of the non-phosphorus corrosion and scale inhibitor are: unsaturated carboxylic acid, natural product, concentrated sulfuric acid, catalyst, hydrogen peroxide, water, etc. The parts by weight of each raw material are:

[0037] Unsaturated carboxylic acid 300

[0038] Natural Products 350

[0039] Concentrated sulfuric acid (98%) 40

[0040] Catalyst 2

[0041] Hydrogen peroxide 260

[0042] water 1600

[0043] The unsaturated carboxylic acid is maleic anhydride; the natural product is papermaking waste residue lignosulfonate; and the catalyst is potassium persulfate.

[0044] The specific preparation method is as follows: first wash the reactor and related equipment, etc., add 1200 kg of water into the reactor, pump 40 kg of sulfuric acid into the reactor under stirring conditions, and add 300 kg of maleic anhydride into the reactor or drop tank Add 350 kilograms of cal...

Embodiment 3

[0046] The natural product is grafted and modified with unsaturated carboxylic acid. The raw materials of the non-phosphorus corrosion and scale inhibitor are: unsaturated carboxylic acid, natural product, concentrated sulfuric acid, catalyst, hydrogen peroxide, water, etc. The parts by weight of each raw material are:

[0047] Unsaturated carboxylic acid 230

[0048] Natural Products 190

[0049] Concentrated sulfuric acid (98%) 70

[0050] Catalyst 15

[0051] Hydrogen peroxide 360

[0052] water 1600

[0053] The unsaturated carboxylic acid is acrylic acid; the natural product is papermaking waste lignosulfonate; and the catalyst is potassium persulfate.

[0054] The preparation method is as follows: first wash the reactor and related equipment, etc., add 1200 kg of water into the reactor, pump 70 kg of sulfuric acid into the reactor under stirring conditions, and add 230 kg of acrylic acid into the reactor or drop tank; Add 190 kg of sodium lignosulfonate and 15 kg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com