Flocculated-adsorption regeneration treating method for waste engine oil

A treatment method and engine technology, applied in the field of lubricants, can solve the problems of harsh reaction conditions, high investment in regeneration equipment, expensive hydrogenation and large-scale treatment, and achieve simple regeneration methods, low investment in regeneration equipment, and reduced secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

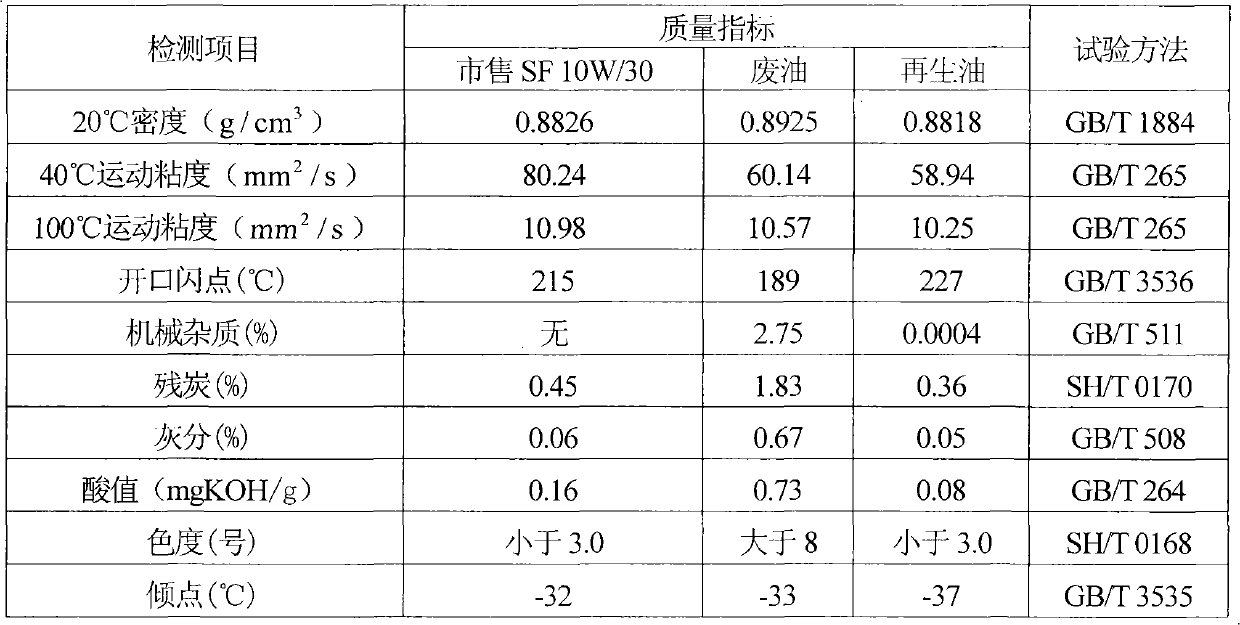

Image

Examples

Embodiment 1

[0024] 1. Sedimentation filtration

[0025] Take 1kg of waste engine oil and put it into a container, settling in a constant temperature box at 65-75°C for 24 hours, take the upper layer of clear oil, and filter.

[0026] 2. Primary flocculation

[0027] In the supernatant clear oil after filtering in step 1, adding mass fraction is 25% sodium carbonate aqueous solution, and the addition amount of the sodium carbonate aqueous solution of 25% is the 2% of supernatant clear oil quality, is heated to 75 ℃, 1000 rev / min constant temperature Stir for 20 minutes, transfer to an incubator at 70-80°C to settle for 16 hours, cool down to room temperature naturally, and take a flocculation supernatant clear oil.

[0028] 3. Secondary flocculation

[0029] Adding a mass fraction of 25% polyamide resin-ethanol solution to the primary flocculation supernatant clear oil, the amount of the 25% polyamide resin-ethanol solution being 10% of the primary flocculation supernatant clear oil mass...

Embodiment 2

[0033] In the primary flocculation step 2 of the present embodiment, the mass fraction of 25% sodium carbonate aqueous solution is 1% of the supernatant clear oil quality, and the other steps of this step are the same as in Example 1. In the secondary flocculation step 3, the addition amount of the polyamide resin-ethanol solution with a mass fraction of 25% is 2.5% of the mass of the supernatant clear oil, and the other steps of this step are the same as in Example 1. In the adsorption decolorization step 4, the addition of the hydrogen peroxide decolorizer is 1% of the quality of the supernatant clear oil in the secondary flocculation, and the total addition of activated clay is 2% of the quality of the upper clear oil. Other steps of this step are the same as in Example 1 . Other steps are the same as in Example 1 to obtain regenerated lubricating oil.

Embodiment 3

[0035] In the primary flocculation step 2 of the present embodiment, the mass fraction of 25% sodium carbonate aqueous solution is 6% of the supernatant clear oil quality, and the other steps of this step are the same as in Example 1. In the secondary coagulation step 3, the polyamide resin-ethanol solution with a mass fraction of 25% is added in an amount of 15% of the supernatant clear oil mass, and other steps of this step are the same as in Example 1. In the adsorption decolorization step 4, the addition of hydrogen peroxide decolorizer is 5% of the quality of the clear oil in the upper layer of the secondary flocculation, and the total amount of activated clay is 14% of the quality of the clear oil in the upper layer. Other steps of this step are the same as in Example 1 . Other steps are the same as in Example 1 to obtain regenerated lubricating oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com