Proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and quality, applied in fuel cells, electrical components, electrochemical generators, etc., can solve the problems of reducing membrane conductivity, reducing cathode efficiency, fuel waste, etc., and achieves good compatibility and good mechanical strength , better than the effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

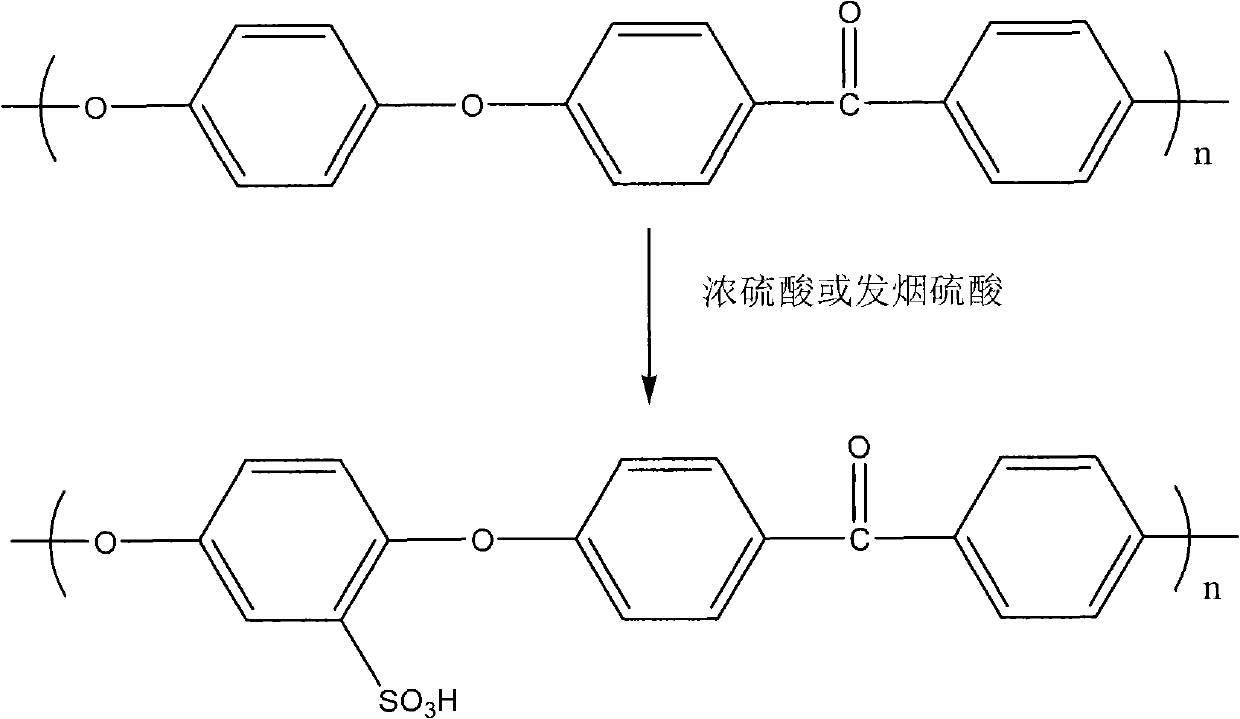

[0026] The preparation method of SPEEK is shown in Scheme 1. According to the mass calculation, weigh 1 part of PEEK (commercial product, model: VICTREX 450P) in 20 to 100 parts of 98% concentrated sulfuric acid, and stir vigorously at room temperature to 60 ° C for 2 ~ After 24 hours, the product is poured into a large amount of water for precipitation to obtain SPEEK with a sulfonation degree of 60-100%.

[0027]

[0028] Scheme 1 PEEK sulfonation reaction to prepare SPEEK

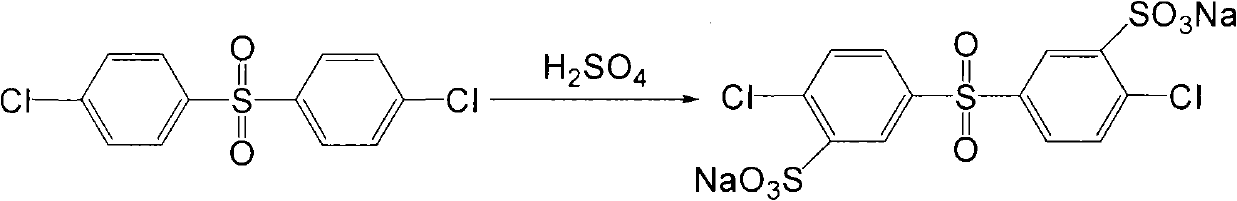

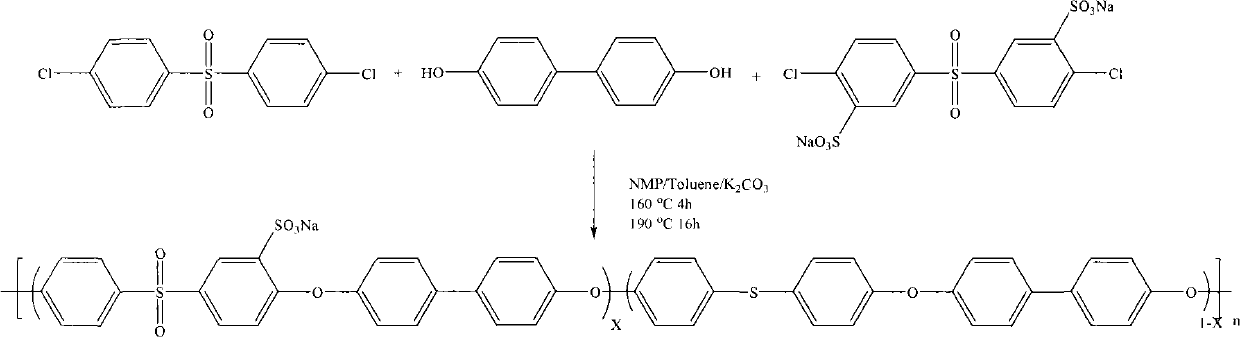

[0029] The preparation of PBPSH with a sulfonation degree of 0-60% is divided into 3 steps: 1) As shown in scheme 2, according to the number of moles, weigh 1 part of dichlorodiphenyl sulfone (DCDPS) monomer and add 1-5 In 20-30% oleum, pour it into ice water after reacting for 2-6 hours, add a large amount of sodium chloride to precipitate sulfonated dichlorodiphenyl sulfone (SDCDPS), and use sodium hydroxide to dissolve SDCDPS before polycondensation reaction. Convert to sodium salt type SDCDPS; 2)...

Embodiment 1

[0047] (1) Dissolve 6 grams of PEEK solid in 300 grams of 98% concentrated sulfuric acid, stir vigorously at 60°C, react for 7 hours, pour the product into a large amount of pure water to obtain a fibrous precipitate, and wash it repeatedly with pure water After the aqueous solution became neutral, it was air-dried at 80° C. for 24 hours to obtain a golden yellow SPEEK fibrous solid with a sulfonation degree of about 90%.

[0048] (2) Dissolve 28.7 grams of DCDPS white powder in 60 mL of 30% oleum, react at 110° C. for 6 hours, and pour the product into 400 mL of ice water after cooling to room temperature. Then add 180 grams of sodium chloride to precipitate a white powdery precipitate, filter and dissolve the precipitate in 400 mL of pure water, adjust the pH value to 6-7 with 2M aqueous sodium hydroxide solution, then add 180 grams of sodium chloride to precipitate white SDCDPS Powdery precipitate, after filtration, the precipitate was vacuum-dried at 120° C. for 48 hours t...

Embodiment 2

[0057] Prepare SPEEK and PBPSNa with the preparation method identical with embodiment 1, and prepare blend membrane with the method identical with embodiment 1, prepared blend membrane contains the SPEEK that sulfonation degree is 90% and sulfonation degree is 35% PBPSH, the difference is that the blending mass ratio of the two SPEEK accounted for 30%.

[0058] The proton exchange membrane mechanical property and proton conductivity that the present embodiment makes are as shown in table 2:

[0059] Table 2 SPEEK film, PBPSH film, blend film and Nafion of Example 2 115 film performance comparison a

[0060]

[0061] Note: a Proton conductivity is tested in pure water environment; b The film was dissolved in hot water at 80°C.

[0062] It can be seen from Table 2 that due to the low proportion of SPEEK in the blended membrane, the performance of the blended membrane is similar to that of the PBPSH membrane. The membrane has excellent thermal stability and chemical sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of sulfonation | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

| Degree of sulfonation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com