Preparation method of capsicine micro spheres

A technology of capsaicin and microspheres, applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of low oral bioavailability and short half-life, and achieve large market development Prospects, reduced toxicity, and effects of avoiding the hepatic first-pass effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

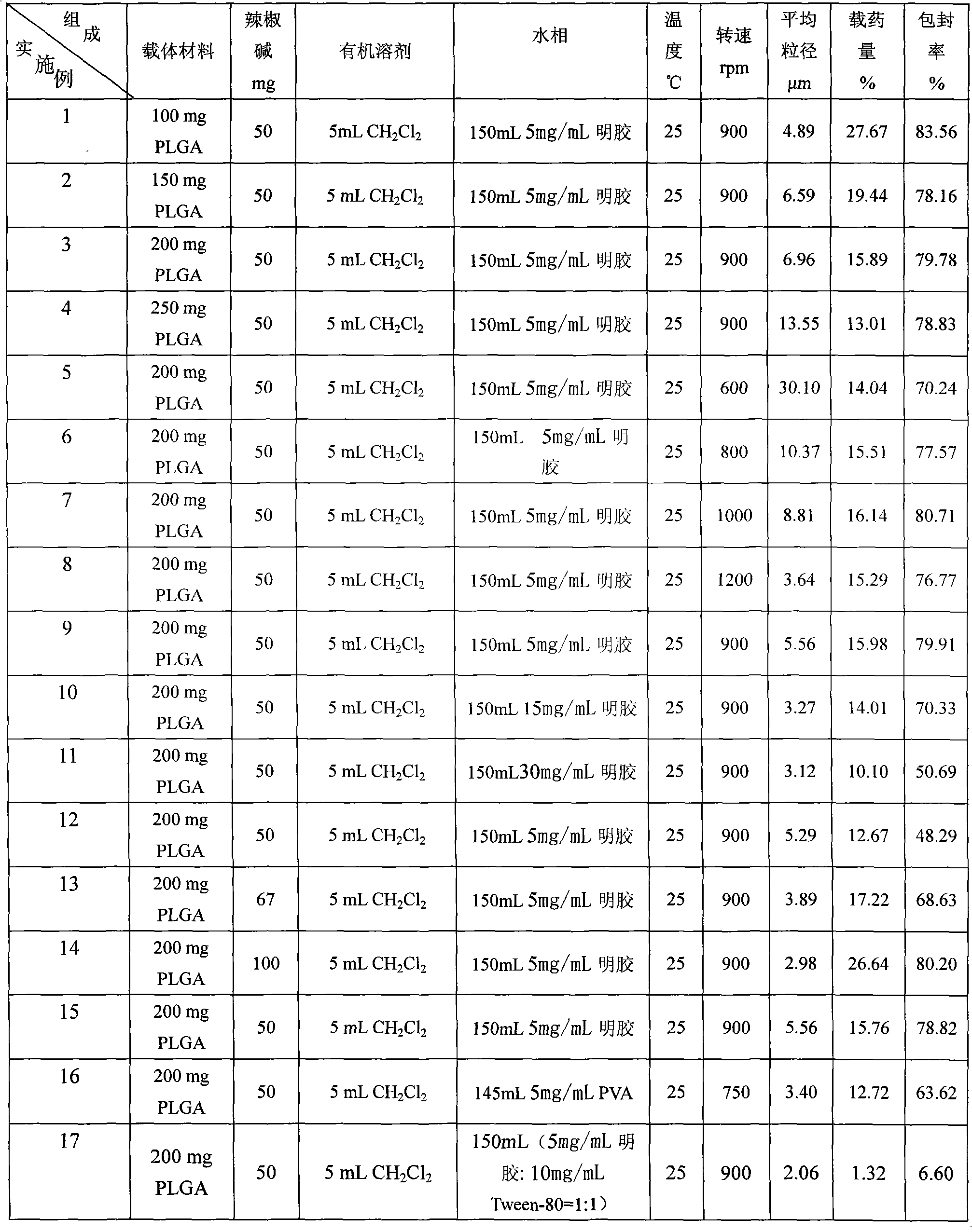

[0026] The present invention will be further described below in conjunction with specific examples.

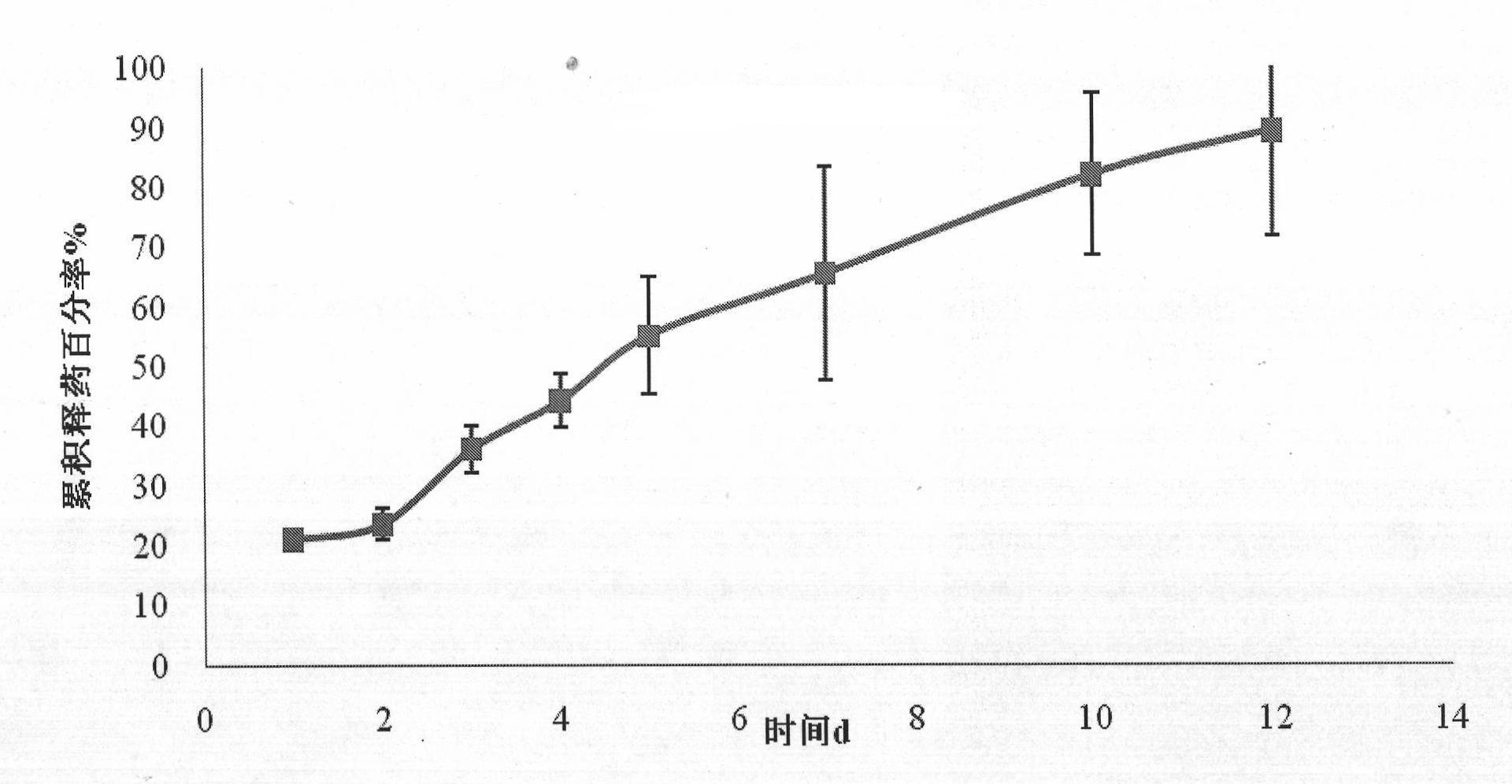

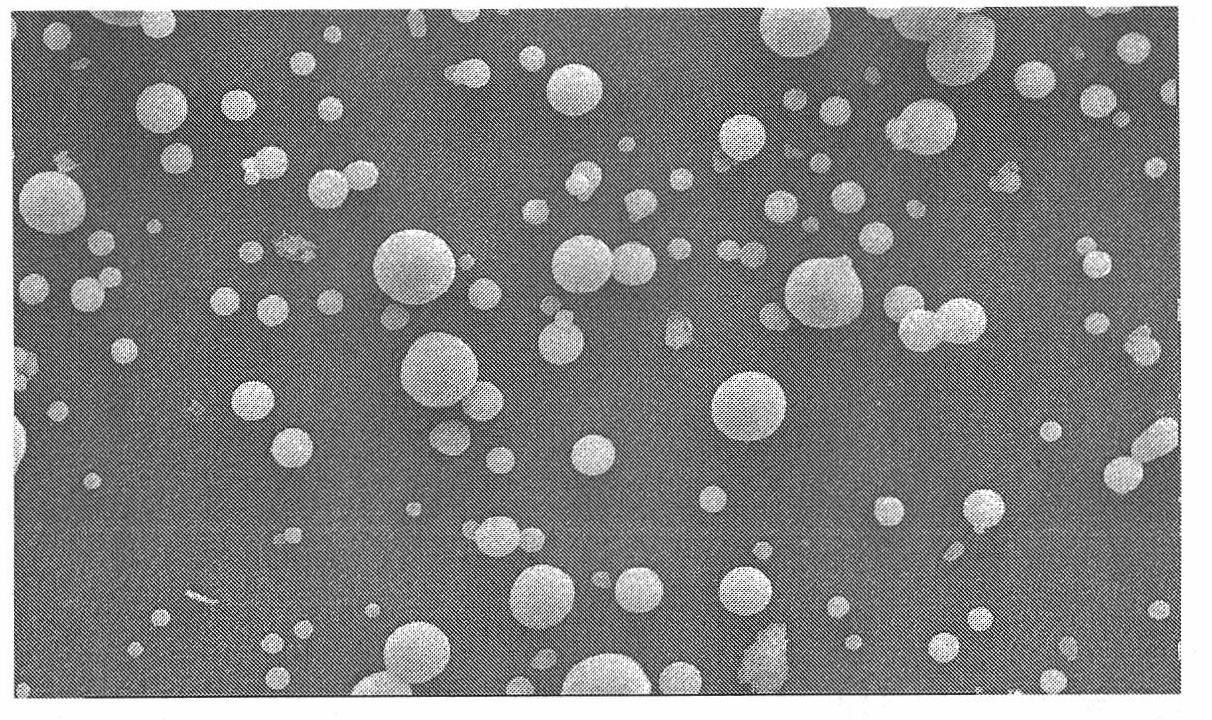

[0027] Precisely weigh a certain amount of capsaicin and a carrier material, add it into a certain volume of organic solvent, and dissolve it by ultrasonic as the oil phase. An aqueous solution containing a certain amount of emulsifier is used as the water phase. Control a certain temperature and mechanical stirring speed, and add the oil phase to the water phase. After emulsification, continue to stir to evaporate the volatile solvent, centrifuge at 3000rpm for 5min, pour off the supernatant to collect microspheres, add distilled water to wash 3 times, collect by centrifugation and freeze-dry. Examples 1-32 specific prescription process and the average particle size, drug loading and encapsulation efficiency of the prepared microspheres are shown in Table 1.

[0028] Table 1 Average particle size, drug loading and encapsulation efficiency of capsaicin microspheres in Exampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com