Preparation method of total terpene lactones with low phenolic acid

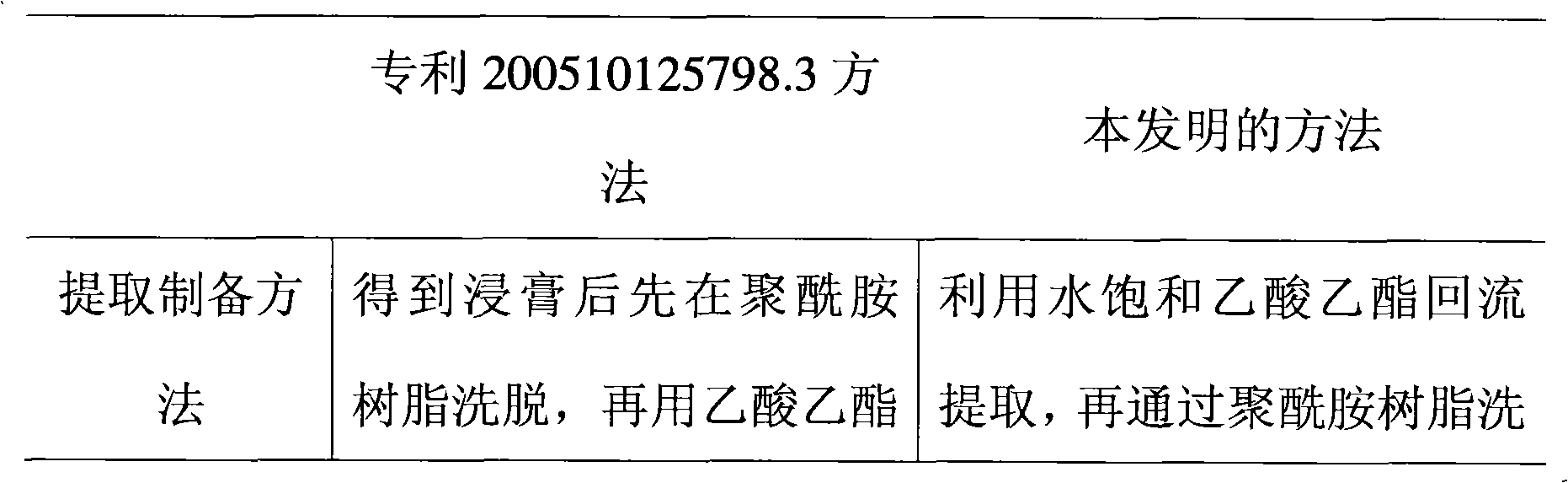

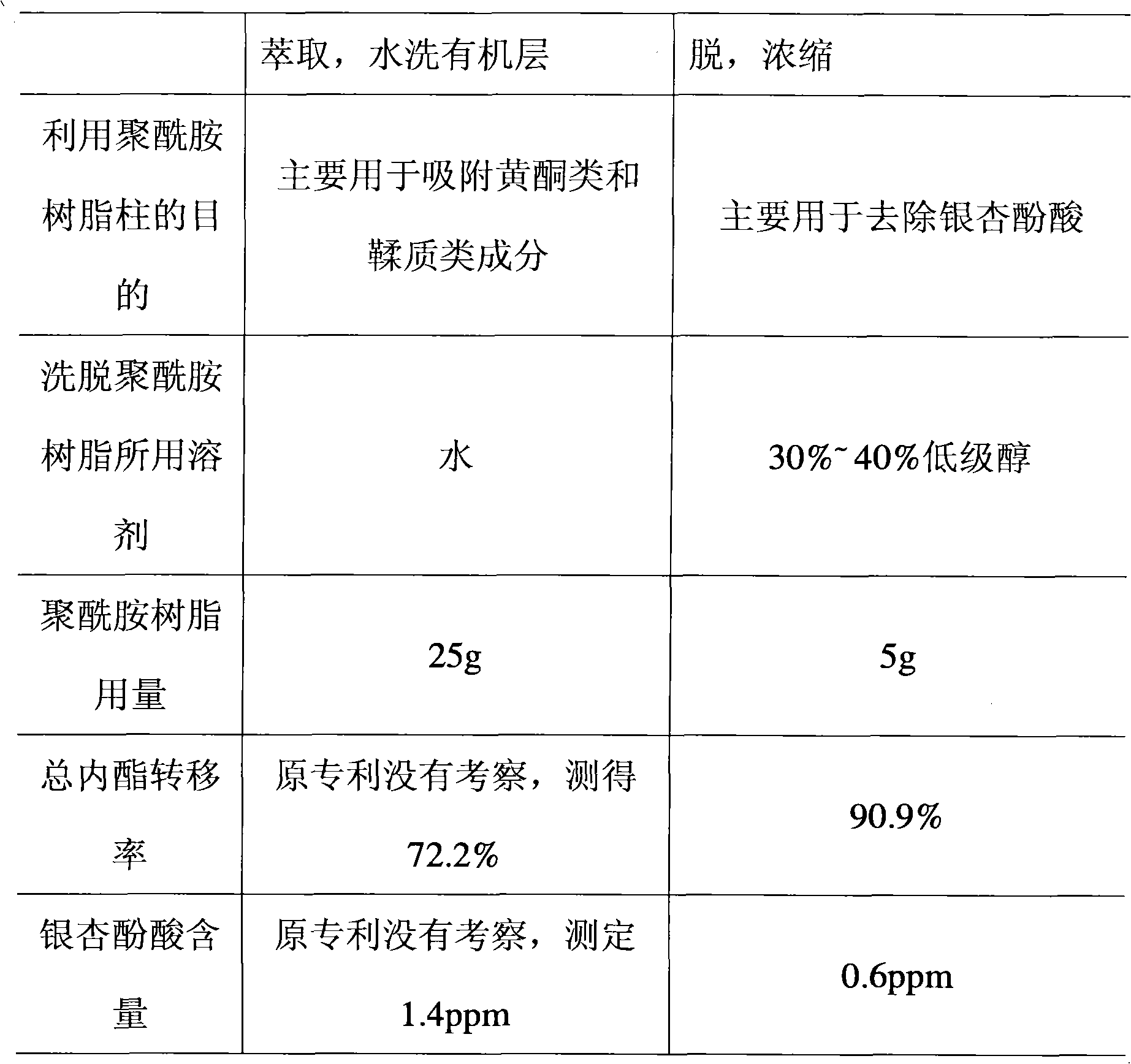

The technology of total ginkgo lactone and phenolic acid is applied in the field of preparation of natural medicine ginkgo total lactone, which can solve the problems that the safety requirements of ginkgo products cannot be met, and achieve the effects of simple operation, reduction of production cost and solvent saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

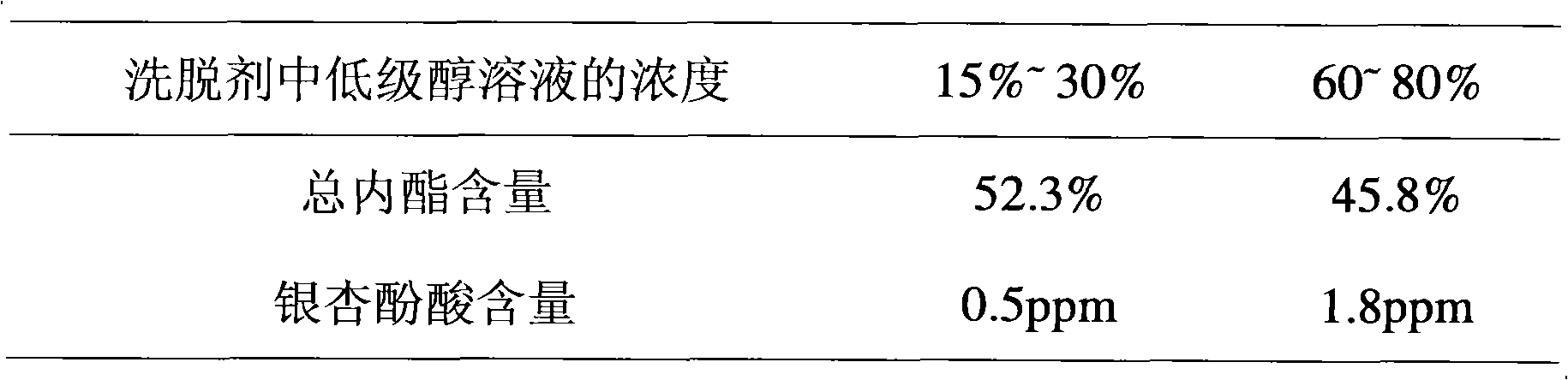

[0032] Take 1000 grams of ginkgo extract as raw material, put it in an extraction tank, use water-saturated ethyl acetate as a solvent, the weight-to-volume ratio of the extract to the solvent is 1:3 (W / V), stir and extract at 60°C for 1 hour, filter , concentrate the filtrate to get medicinal extract; after polyamide resin adsorption, 20% ethanol elutes in the polyamide resin column, collects fraction, concentrates and dries, pulverizes and obtains ginkgo lactone powder, result: powder total lactone content 52.9%, ginkgo biloba Acid content 0.5ppm.

Embodiment 2

[0034] Take 1000 grams of ginkgo extract as raw material, place it in an extraction tank, use water-saturated ethyl acetate as a solvent, the weight-to-volume ratio of the extract to the solvent is 1:2 (W / V), stir and extract at 60°C for 1 hour, Filtrate and concentrate the filtrate to obtain the extract; mix the extract with polyamide, elute with 15% ethanol in the polyamide resin column, collect the fractions, concentrate and dry, and pulverize to obtain the total ginkgo lactone powder. The result: the total lactone content of the powder is 50.2 %, ginkgolic acid content 0.5ppm.

Embodiment 3

[0036] As shown in Example 2, the difference is that the extraction temperature of Example 2 is 60°C, while that of Example 3 is 70°C. Results: The total lactone content of the powder was 51.4%, and the ginkgolic acid content was 0.5ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com