Dispersant for dispersing carbon nano-tube and preparation method of carbon nano-tube film

A technology of carbon nanofilm and carbon nanotube, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of reducing the transmittance of the film, and achieve the effect of favorable performance and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

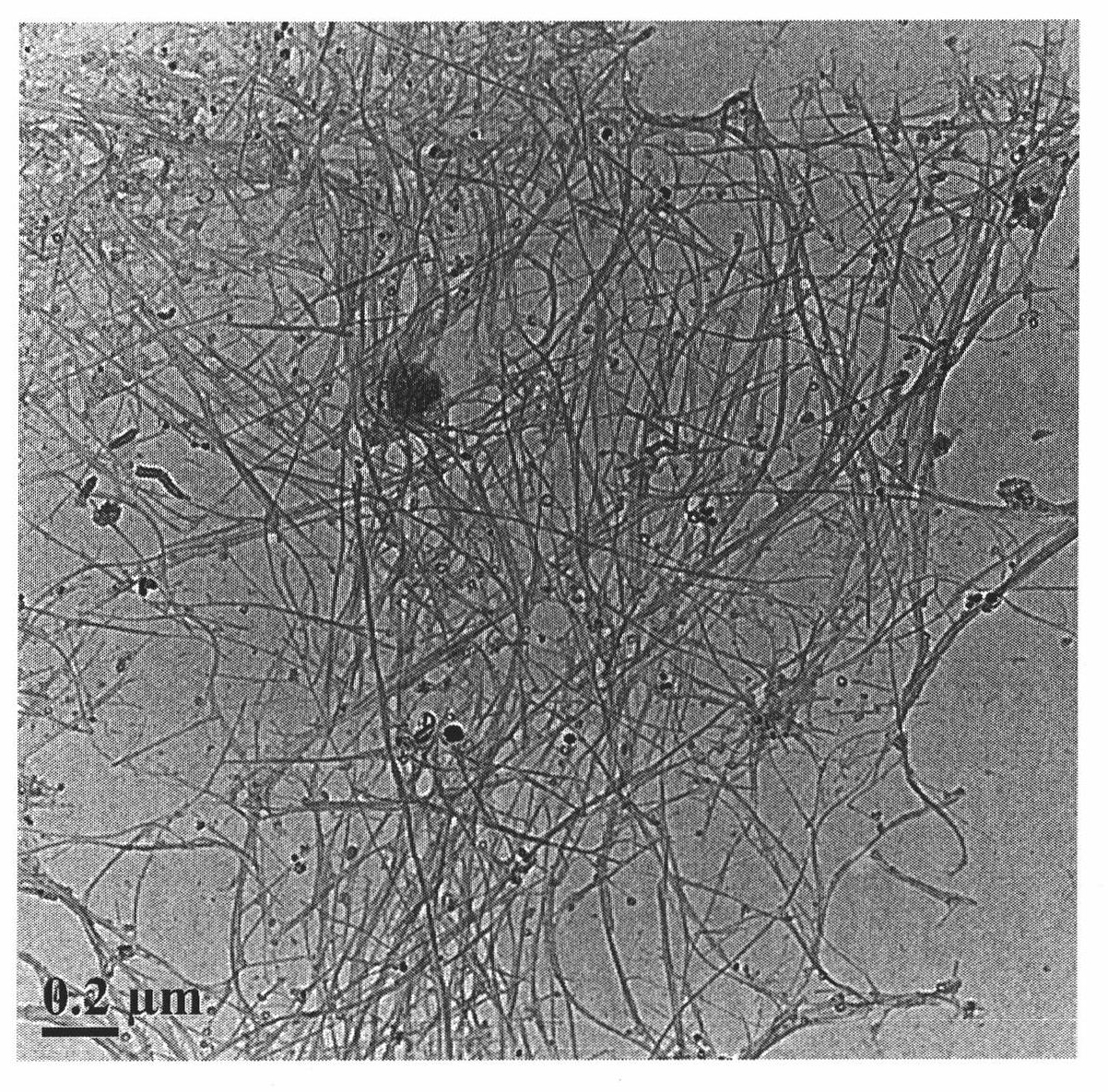

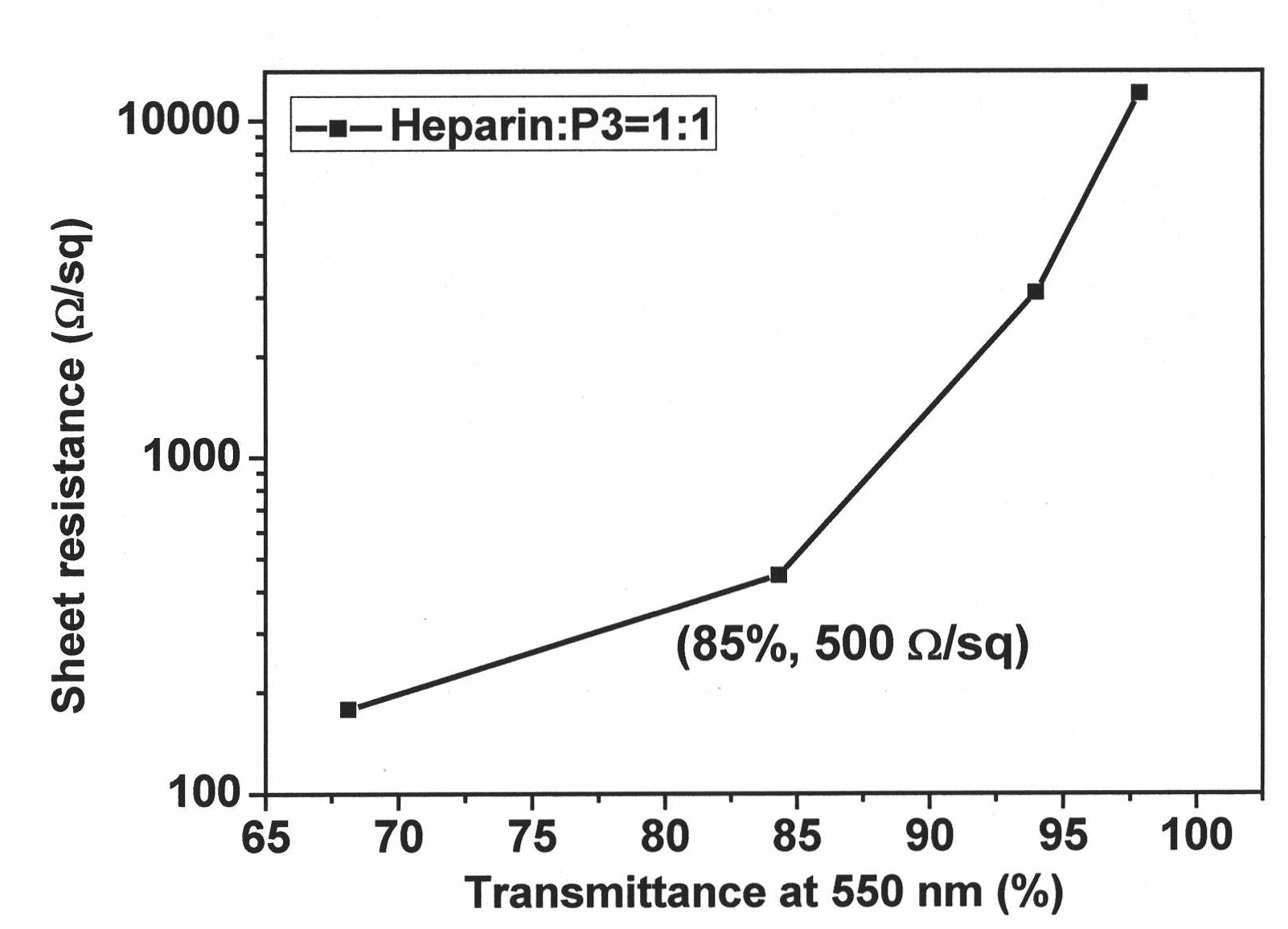

[0032] Add 10 mg of heparin into 50 mL of deionized water, stir to dissolve. Then add 10 mg of single-wall or multi-wall carbon nanotubes, and sonicate in a water bath for 2 hours to obtain a black suspension. Then the suspension was centrifuged at 13000rpm for 30min, the supernatant was taken, the above centrifugation process was repeated once, the supernatant was diluted 10 times, and then 10-50mL were taken for vacuum filtration to form a carbon nanotube film. The filter membrane and the membrane formed on it were transferred to the substrate together, dried in the air at 60° C. for 2 hours, and then soaked in acetone for 30 minutes to remove the filter membrane. The obtained carbon nanotube film was finally dried at 60° C. for 3 hours. The transmittance of the film was measured by ultraviolet-visible spectrometer, and the film resistance was measured by four-probe resistivity meter. figure 1 It is a transmission electron microscope photo of the obtained supernatant, and ...

Embodiment 2

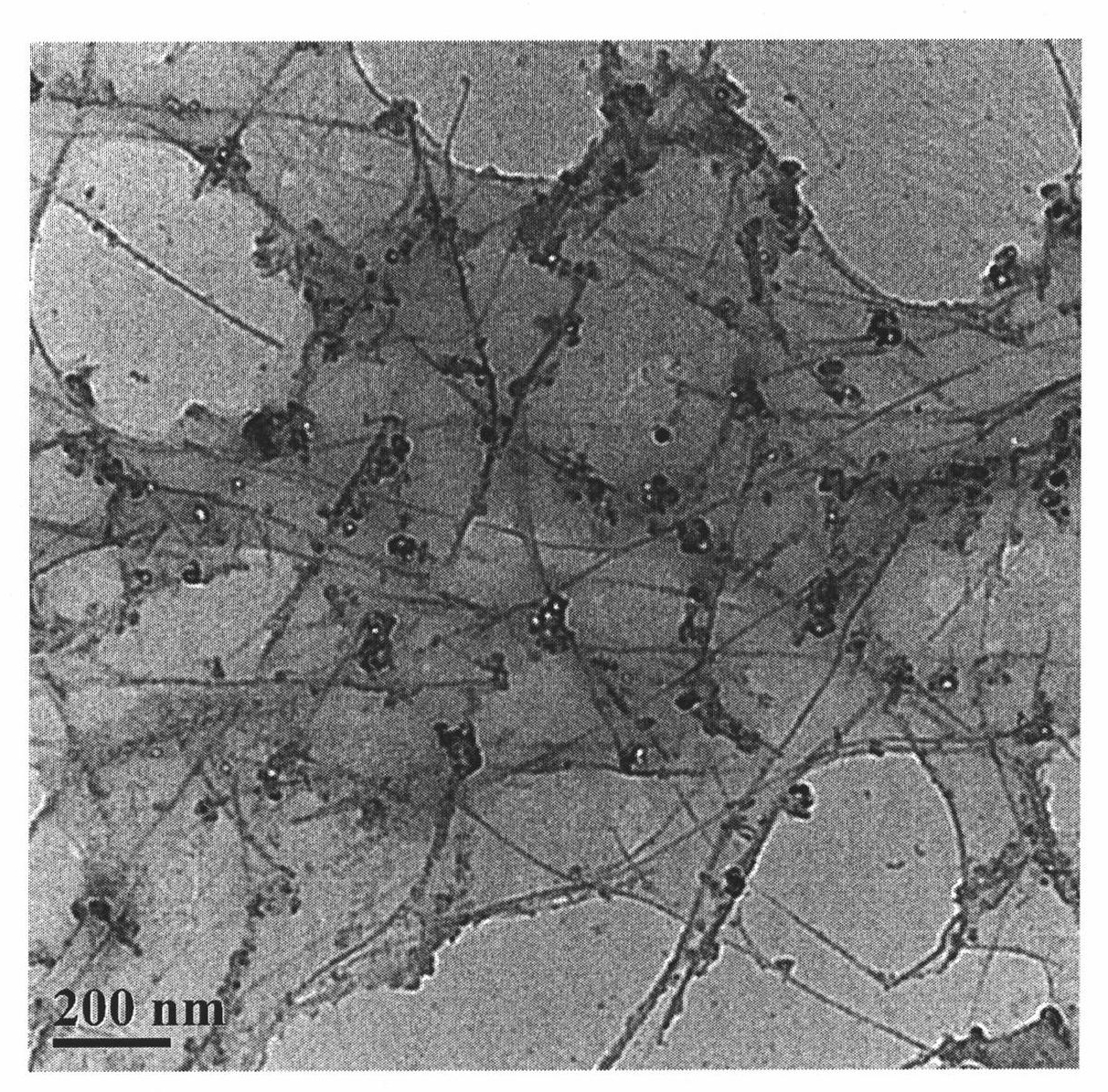

[0034]Add 5 mg of RNA to 50 mL of deionized water, stir magnetically until the RNA is completely dissolved, then add 10 mg of single-walled carbon nanotubes, and sonicate in a water bath for 2 hours to obtain a black suspension. Centrifuge the above suspension at 13000rpm for 30min, take the supernatant, repeat the centrifugation once, take the supernatant and dilute it 20 times, then take 10-60mL of the diluted solution respectively, and prepare a transparent conductive film by vacuum filtration. Concrete molding step is the same as embodiment 1. image 3 It is a transmission electron microscope photo of the obtained supernatant, it can be seen that the carbon tubes are uniformly dispersed, and the size of the tube bundle is about 5-7 nm. A thick film of organic matter can also be seen in the photo, indicating that not all the RNA was adsorbed on the carbon nanotubes, and a large amount remained in the solution. When the amount of RNA is reduced to 2.5mg, this phenomenon wil...

Embodiment 3

[0036] Add 10 mg of DNA to 50 mL of deionized water, stir magnetically until it is completely dissolved, then add 10 mg of multi-walled carbon nanotubes, sonicate the probe for 10 min in an ice-water bath, and then sonicate in a water bath for 1.5 h to obtain a black suspension. Centrifuge the obtained black suspension at 13000rpm for 30min, take the supernatant, repeat the centrifugation twice, and finally dilute the supernatant 10 times, take 10-40mL respectively to prepare a transparent conductive film by vacuum filtration, measure its resistance, permeability Rate. Then soak the film in concentrated nitric acid for 10 minutes to 8 hours, and then measure its resistance and transmittance. Figure 6 It is a transmission electron micrograph of a carbon nanotube suspension prepared with DNA as a dispersant. It can be seen that the carbon tubes are uniformly dispersed, and the size of the tube bundle is small, mostly 3-5 nm. Depend on Figure 7 It can be seen that the resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com