Method for producing energy-saving and environmentally-friendly concrete

An energy saving, environmental protection, production method technology, applied in chemical instruments and methods, clay preparation devices, sustainable waste treatment, etc., can solve the problems of small allowable change performance, reduced living area, increased wall thickness, etc. The effect of thermal insulation performance, increasing living area and reducing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

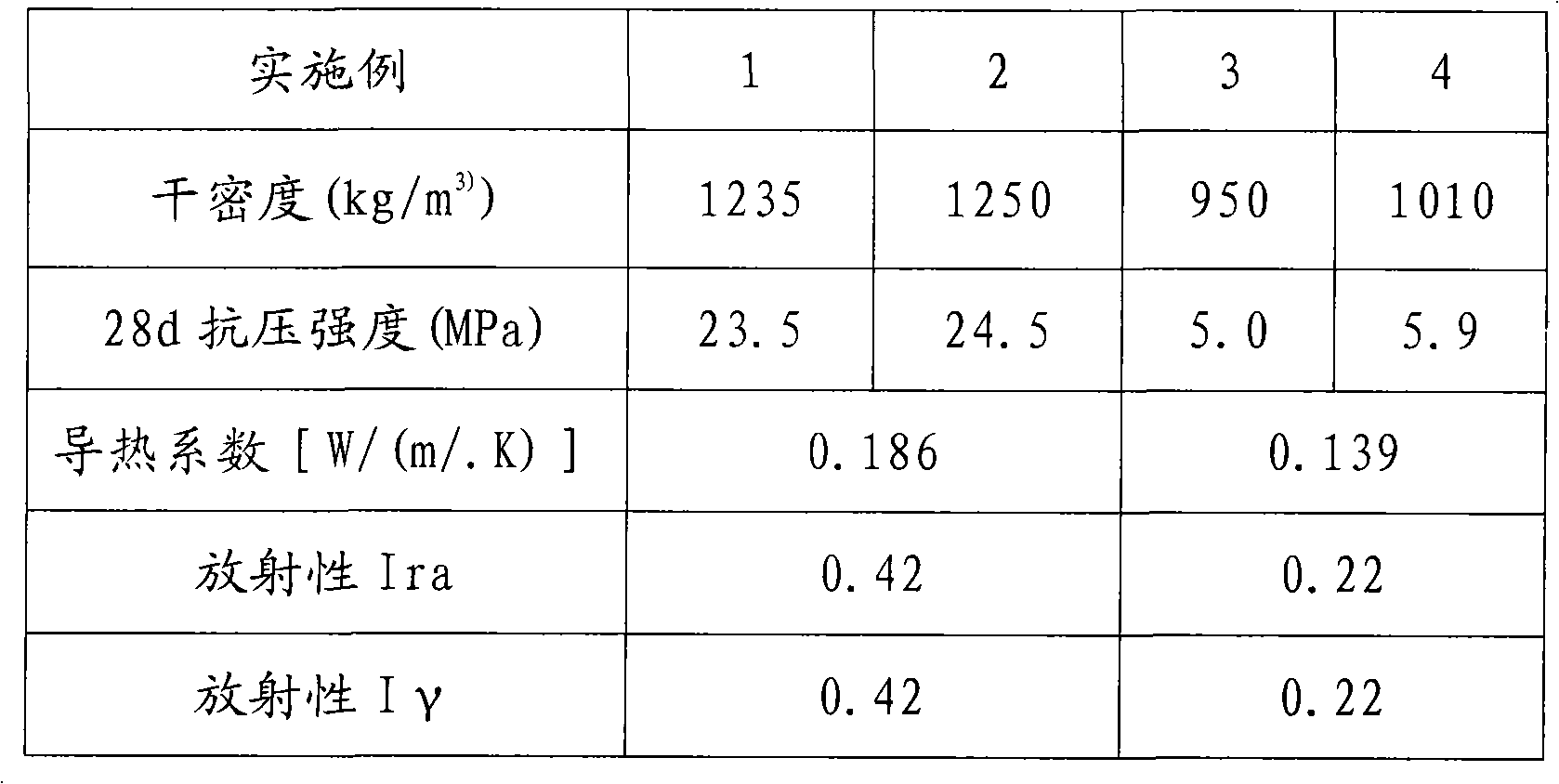

Examples

Embodiment 1

[0063] Cement 143

[0064] Fly Ash 12

[0065] mountain sand 43

[0066] Ceramsite 95

[0067] Phosphorus slag sand 100

[0068] water 54

[0069] Polycarboxylate superplasticizer 1.7

Embodiment 2

[0071] Cement 105

[0072] Fly Ash 11

[0073] mountain sand 39

[0074] Ceramsite 86

[0075] Phosphate slag sand 90

[0076] water 41

[0077] Polycarboxylate superplasticizer 1.3

Embodiment 3

[0079] Cement 57

[0080] fly ash 38

[0081] Ceramsite 79

[0082] Phosphate slag sand 43

[0083] water 40

[0084] Polycarboxylate superplasticizer 0.7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com