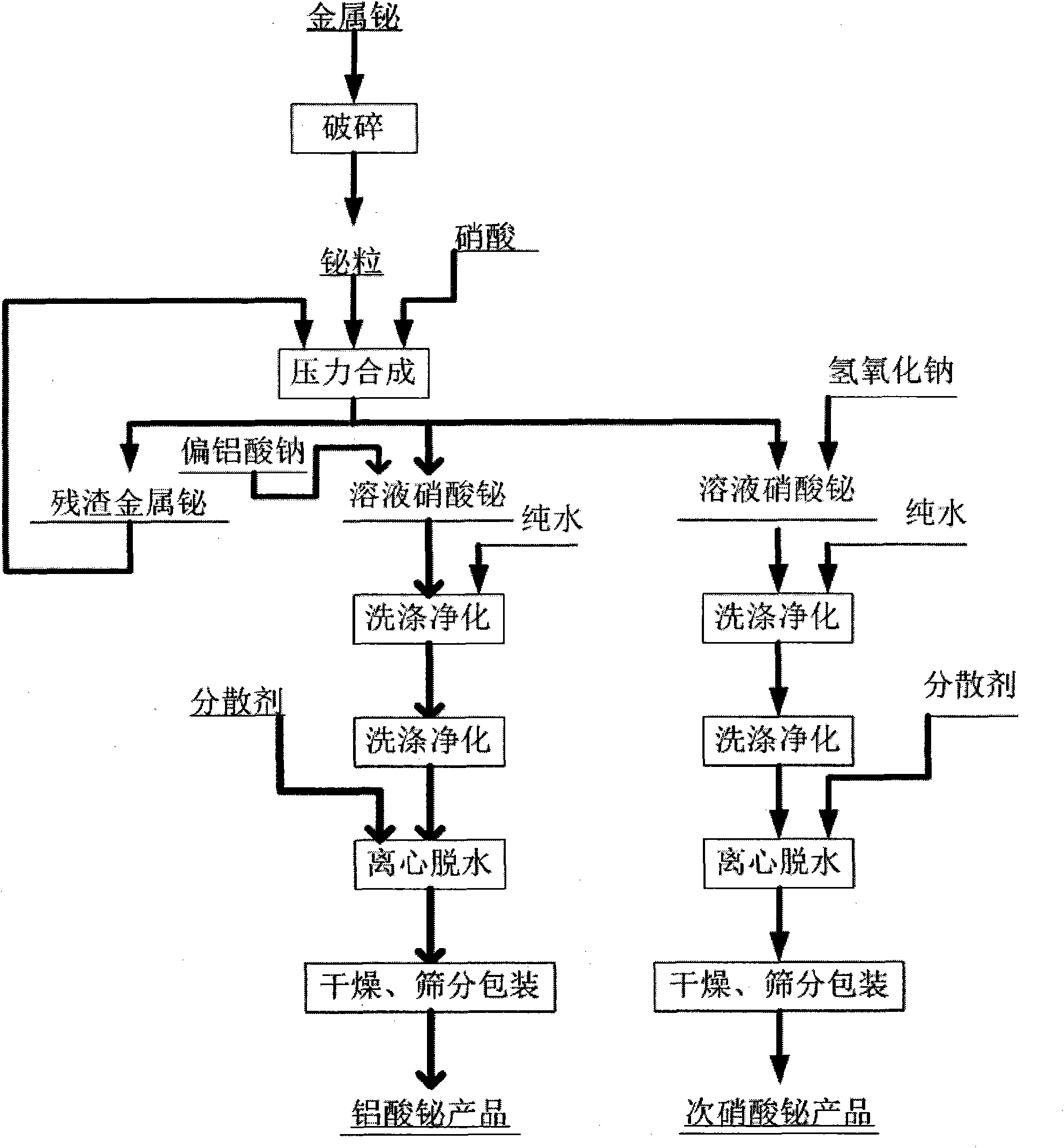

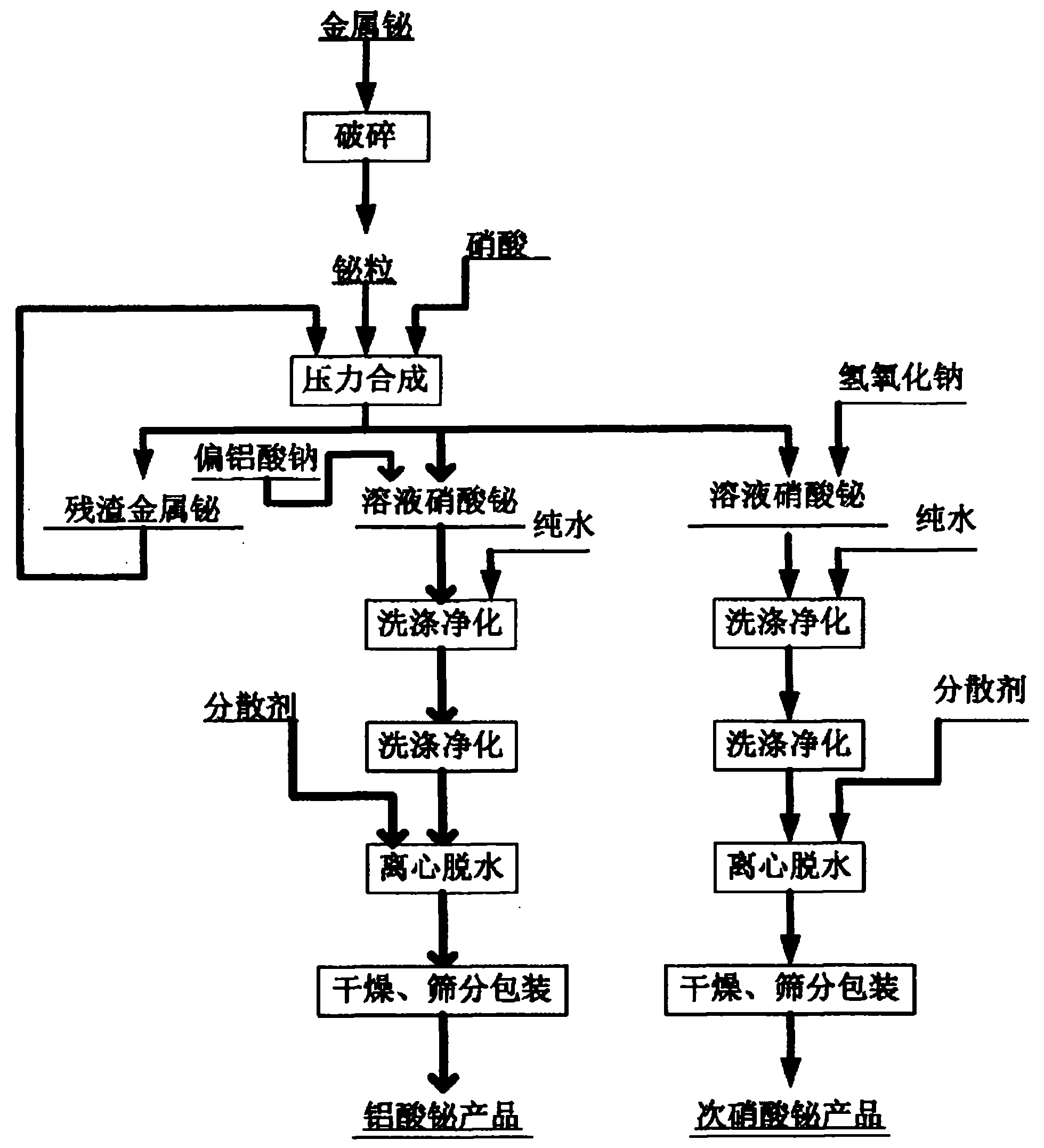

Method for synthesizing bismuth subnitrate and bismuth aluminate

A bismuth subnitrate and synthesis method technology, applied in bismuth compounds, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as no public reports, and achieve the effects of reducing energy consumption, high conversion rate of bismuth, and increasing reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Add 5Kg of metal bismuth particles with a particle size of 5 mm in a 50-liter pressure vessel, 16.7 liters of 30% industrial nitric acid, pass cooling water to control the temperature at 140° C., pressure at 1.0 MPa, and the reaction time for 1.5 hours. After the reaction, the liquid and solid were separated to obtain 0.5 Kg of the reaction residue and 17 liters of the intermediate product bismuth nitrate solution. The composition of the reaction intermediate product bismuth nitrate solution is: free nitric acid 8%, bismuth 254g / L, iron 0.0008g / L, lead 0.005g / L. Add 4.5Kg of metal bismuth particles to the reaction residue, return 16.7 liters of 30% industrial nitric acid to the pressure vessel, control the mass ratio of metal bismuth to nitric acid to be 1.0, react under the above reaction conditions, and add nitric acid and metal bismuth to return the reaction residue after the reaction , and back and forth. The intermediate product bismuth nitrate solution produced b...

Embodiment 2

[0033] Add 10Kg of metal bismuth grains with a particle size of 10 mm, 11.7 liters of 60% industrial nitric acid in a 50-liter pressure vessel, pass cooling water to control the temperature at 170° C., pressure at 1.6 MPa, and the reaction time for 1.0 hour. After the reaction was finished, the liquid and solid were separated to obtain 0.5 Kg of the reaction residue and 12 liters of the intermediate product bismuth nitrate solution. The composition of the reaction intermediate product bismuth nitrate solution is: free nitric acid 2%, bismuth 790g / L, iron 0.0005g / L, lead 0.003g / L. Reaction residue replenishes metal bismuth particles 9.5Kg, 11.7 liters of 60% industrial nitric acid returns to the pressure vessel, controls the mass ratio of metal bismuth to nitric acid to be 0.7, reacts under the above reaction conditions, and the residue after the reaction supplements nitric acid and metal bismuth to return to the reaction , and back and forth. The intermediate product bismuth ...

Embodiment 3

[0035] Basically with embodiment 1. The difference is:

[0036] In the preparation of the intermediate product bismuth nitrate: metal bismuth particle size is 8 millimeters, nitric acid concentration is 60%, nitric acid addition is 5.83 liters, metal bismuth and nitric acid mass ratio are 1: 0.7, reaction temperature 170 ℃, reaction pressure 1.6Mpa, reaction After 1.0 hour, 0.65 Kg of the reaction residue and 5.5 liters of the intermediate product bismuth nitrate solution were obtained.

[0037] In the preparation of the bismuth subnitrate product: add sodium hydroxide to neutralize, add sodium hydroxide to neutralize the end point pH value 2.0, the addition of liquid dispersant ethanol is 1% of product weight, obtain 6.3 kilograms of bismuth subnitrate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com