Method for preparing silicon nitride and silicon carbide compounded powder through self-propagating combustion

A technology of silicon nitride composite silicon carbide and self-propagating combustion, which is applied in the field of inorganic non-metallic materials, can solve the problems of complex process, poor mixing effect and high production cost of silicon nitride composite silicon carbide powder, and achieve the convenience of grinding after grinding Good treatment and sintering activity and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

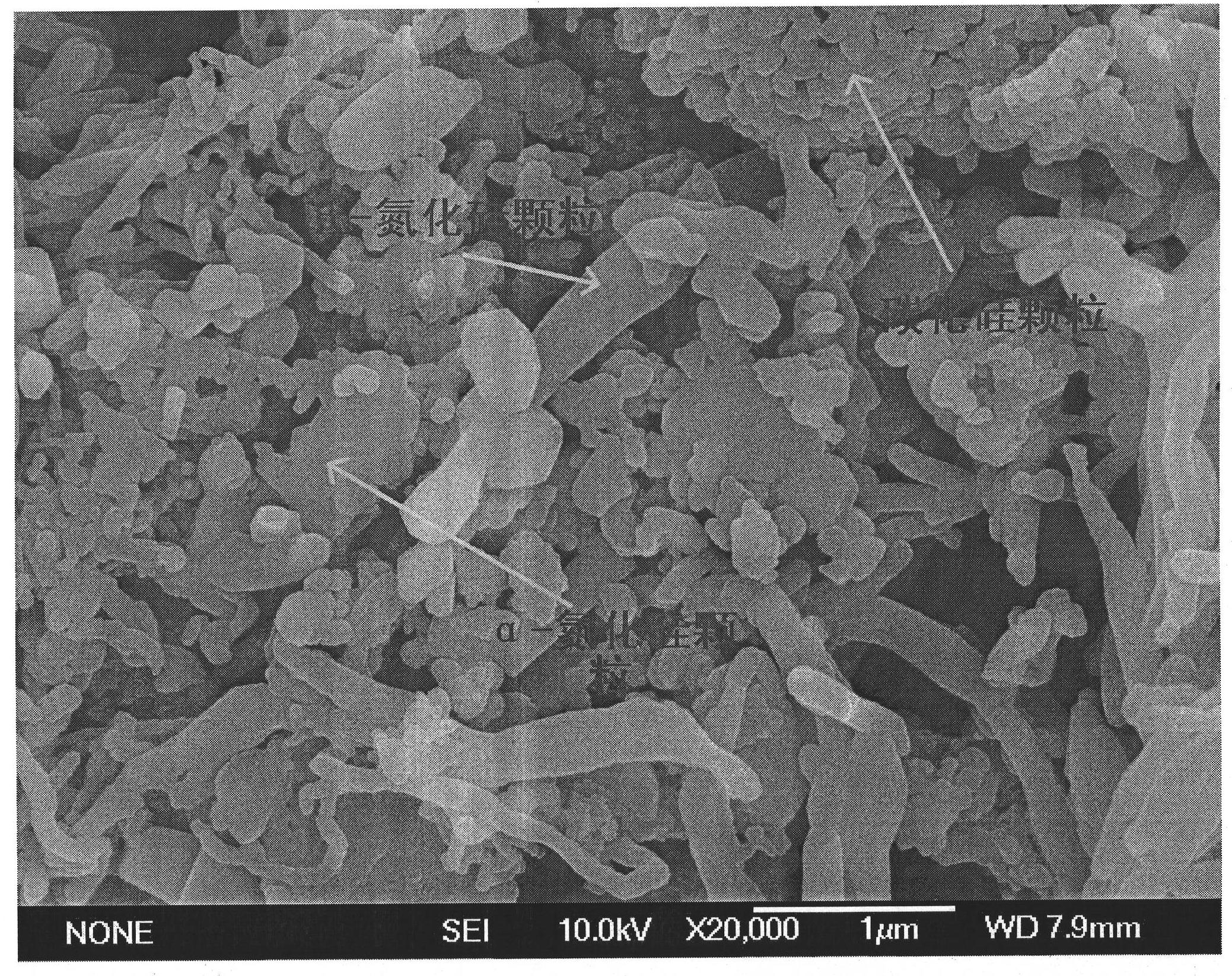

[0025] Example 1, 300 mesh metal silicon powder, purity > 98.5%, iron content < 0.8%, with steel balls as the ball milling medium, placed in a steel tank, material: ball weight ratio is 1: 2, on a planetary ball mill Carry out 12 hours of ball milling; the silicon powder after ball milling is as the raw material of next step mixing; By weight metal silicon powder (after ball milling) is 50%, and weight is 1000 grams, and high-purity carbon black is 5%, and weight is 100 gram, silicon nitride powder body is 45% (average particle diameter is 3 μm), and weight is 900 grams, after mixing, be ball milling medium with steel ball, be placed in corundum tank, material: ball weight ratio is 1: 2, put Stir and ball mill on a pot mill for 1 hour, and the evenly mixed material passes through a 40-mesh sieve, and the sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then put into a self-propagating synthesis reactor, pumped After vacuuming, fill it with 5MPa ...

Embodiment 2

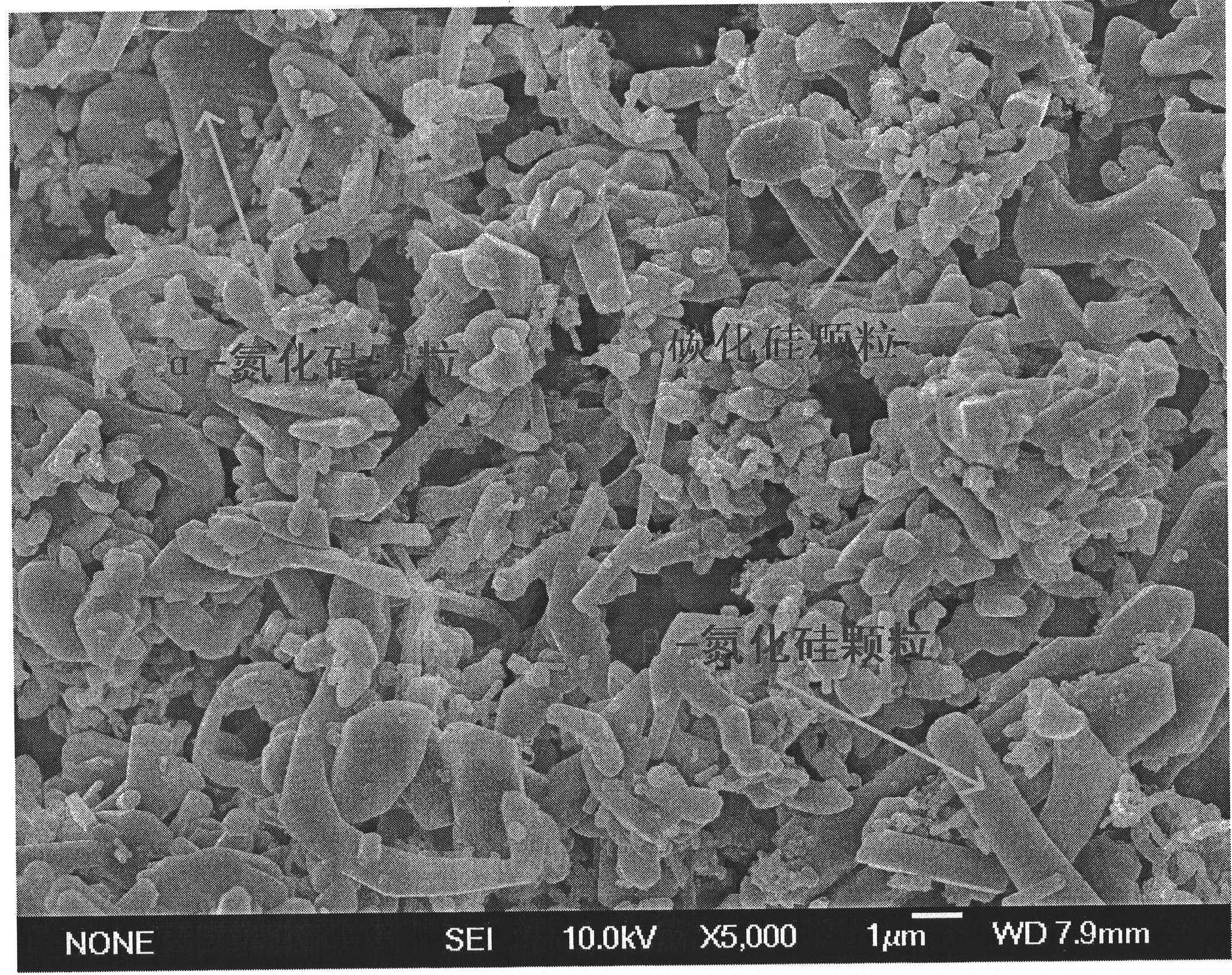

[0027] Example 2, 300 mesh metal silicon powder, purity > 98.5%, iron content < 0.8%, with steel balls as the ball milling medium, placed in a steel tank, material: ball weight ratio is 1: 5, on a planetary ball mill Carry out 16 hours of ball milling, the silicon powder after ball milling is as the raw material of next step mixing; By weight metal silicon powder (after ball milling) is 45%, and weight is 900 grams, and high-purity carbon black is 10%, and weight is 200 grams. gram, silicon nitride powder body is 45% (average particle diameter is 10 μ m), and weight is 900 grams, after mixing, be ball milling medium with steel ball, be placed in corundum tank, material: ball weight ratio is 1: 5, put Stir and ball mill on a pot mill for 4 hours, and the evenly mixed material passes through a 40-mesh sieve, and the sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then put into a self-propagating synthesis reactor, pumped After vacuuming, fill it ...

Embodiment 3

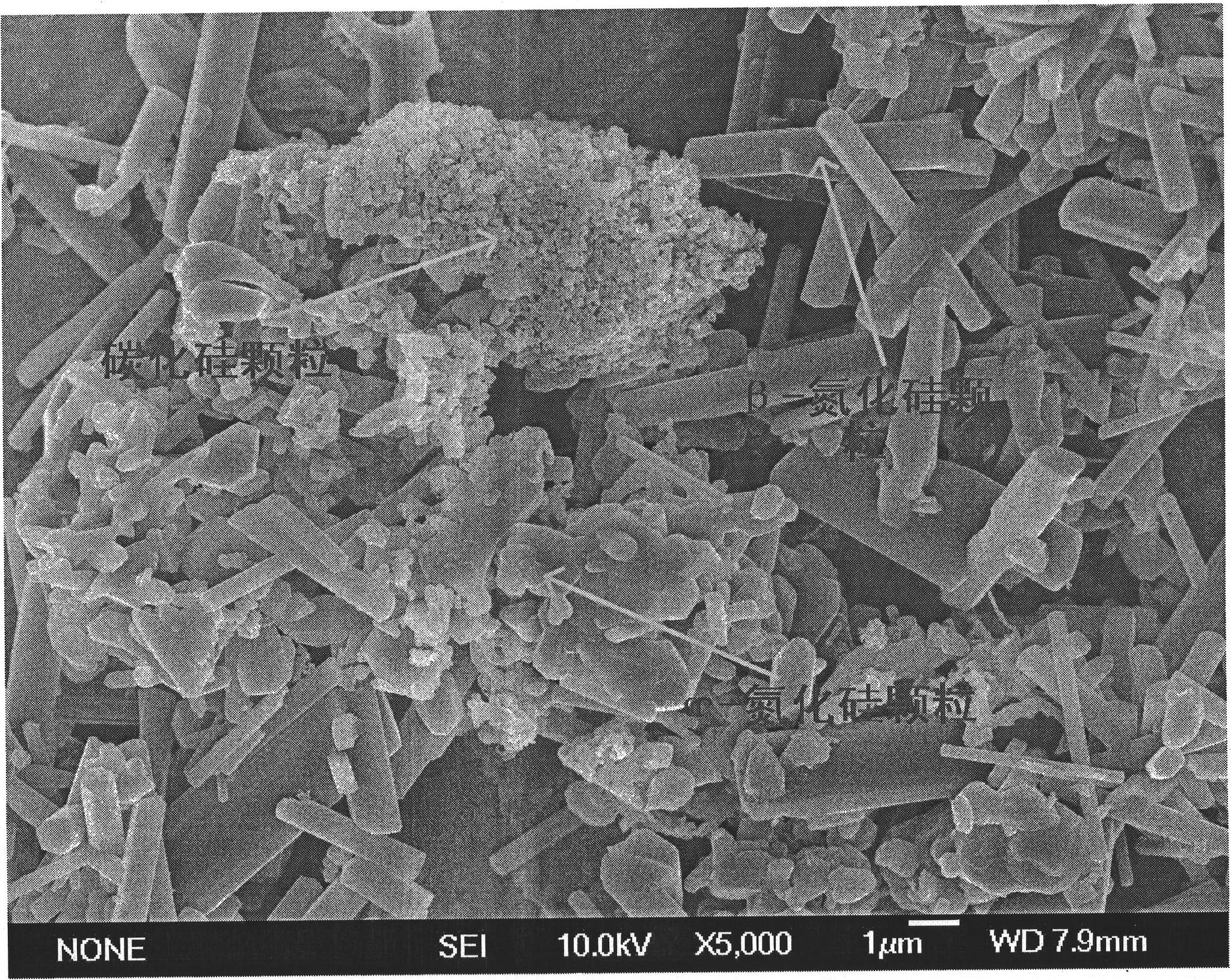

[0029]Example 3, 200 mesh metal silicon powder, purity > 98.5%, iron content < 0.8%, with steel balls as the ball milling medium, placed in a steel tank, material: ball weight ratio is 1: 3, on a planetary ball mill Carry out the ball milling process of 14 hours; The silicon powder after the ball milling is as the raw material of next step mixing; By weight metal silicon powder (after ball milling) is 47%, and weight is 940 grams, and high-purity carbon black is 8%, and weight is 160 gram, silicon nitride powder body is 45% (average particle diameter is 6 μ m), and weight is 900 grams, after mixing, be ball milling medium with steel ball, be placed in corundum tank, material: ball weight ratio is 1: 4, put Stir and ball mill on a pot mill for 3 hours, and the evenly mixed material passes through a 40-mesh screen, and the sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then put into a self-propagating synthesis reactor, pumped After vacuuming, f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com