Method for extracting carotenoid and liquid biological fuel from Dunaliella sallina

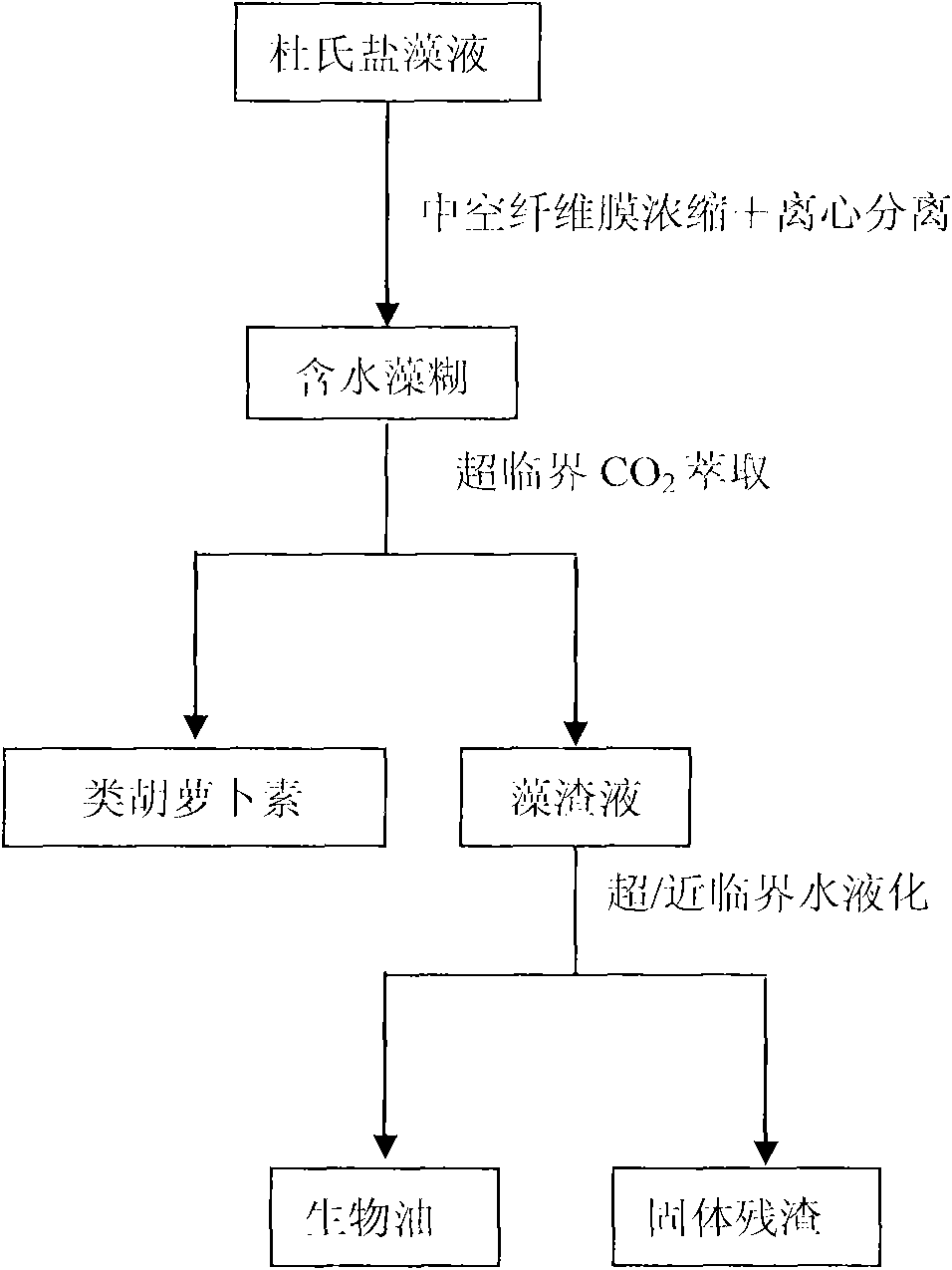

A Dunaliella salina and carotene technology is applied in the production of bulk chemicals, the preparation of liquid hydrocarbon mixtures, and the petroleum industry. It can solve the problems of underutilization of algae residues, low quality ratio, and waste of resources. Easy recycling, simple process and high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

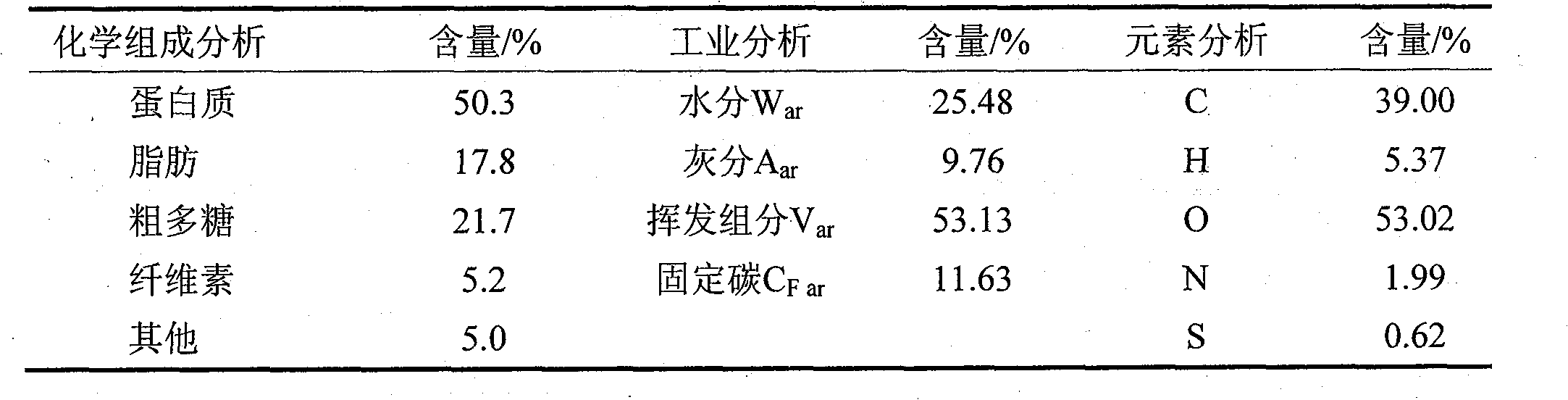

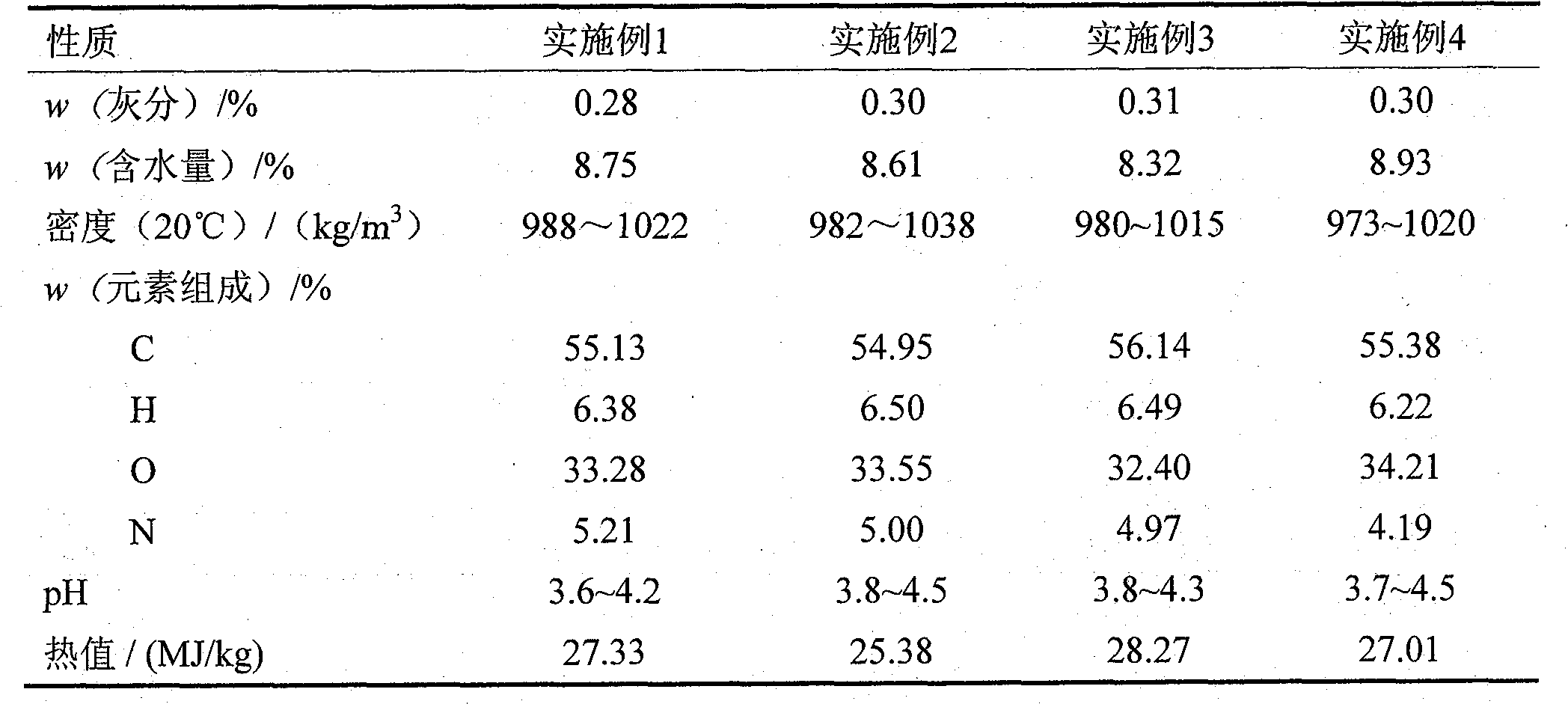

Embodiment 1

[0027] The above water-containing algae paste is extracted with supercritical carbon dioxide to obtain carotenoids and algae residue liquid. The temperature of the supercritical carbon dioxide in the extraction kettle is 35°C and the pressure is 10MPa, and the obtained carotenoid content accounts for 14% of the mass fraction of the product; 17MPa, the reaction time is 40min, using Na 2 CO 3 As a catalyst, when the mass ratio of the catalyst dosage to the algae residue liquid is 4:100, the yield of the obtained biofuel oil is 27%. The properties of the biofuel oil are shown in Table 2.

Embodiment 2

[0029]Carry out supercritical carbon dioxide extraction on the above-mentioned water-containing algae paste, the temperature of the supercritical carbon dioxide in the extraction kettle is 40°C, the pressure is 18MPa, and the obtained carotenoid content accounts for 18% of the mass fraction of the product; then use super / near-critical water to liquefy the algae residue liquid, at a reaction temperature of 340°C, a pressure of 15MPa, and a reaction time of 30min, using K 2 CO 3 It is a catalyst, and the mass ratio of catalyst dosage to algae residue liquid is 2.5:100, and the yield of biofuel oil is 24% under this condition. The properties of biofuel oil are shown in Table 2.

Embodiment 3

[0031] Use supercritical carbon dioxide to extract the above-mentioned water-containing algae paste. The temperature of the supercritical carbon dioxide in the extraction kettle is 40 ° C and the pressure is 16 MPa. The carotenoid content obtained accounts for 16% of the mass fraction of the product; then use super / near critical water to liquefy Algae residue liquid, when reaction temperature is 360 ℃, pressure is 18MPa, reaction time is 20min, adopts KOH as catalyst, when the mass ratio of catalyst dosage and algae residue liquid is 3:100, the productive rate of biofuel oil under this condition is 25%. The properties of biofuel oil are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com