Micro powder graphite carburant, preparation method and use method thereof

A technology of micropowder graphite and recarburizer, which is applied in the field of recarburizers, can solve problems such as environmental pollution, and achieve the effects of reducing production costs, stable recarburization effect, and high fixed carbon content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

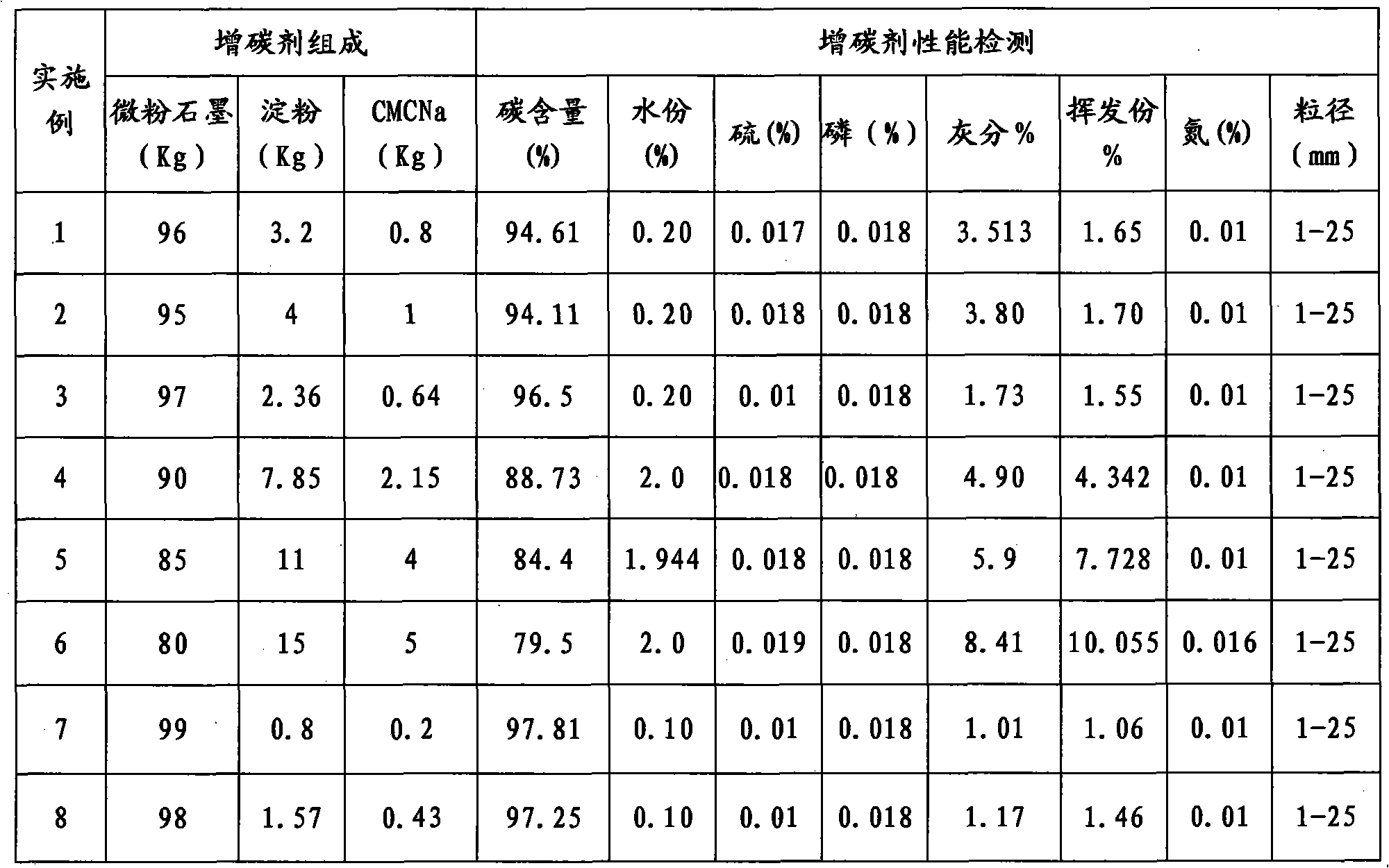

[0048] Examples 1-8 Preparation and Performance Testing of Micropowder Graphite Carburizer of the Present Invention

[0049] The composition and performance detection of the micropowder graphite recarburizer of the present invention described in Examples 1-8 are shown in Table 1, and its preparation method comprises the following steps:

[0050] 1) Weigh the starch or tapioca starch, CMCNa or CMC of the composition described in Table 1, add an appropriate amount of water, stir, and mix uniformly to obtain a binder solution;

[0051] 2) take by weighing the micropowder graphite of composition described in table 1, described micropowder graphite is the graphite tailings that generate in the lithium-ion battery composite negative electrode material process, add 1) the binder solution that step makes, after stirring and mixing, Carry out granulation, dry, sieve treatment, obtain.

[0052] 3) The physical and chemical properties of graphite tailings are tested in Table 1.

[005...

Embodiment 9

[0057] Example 9 Carburizing Effect Test of Micropowder Graphite Carburizing Agent of the Present Invention

[0058] According to the method for steel smelting, the micropowder graphite recarburizer of the embodiment of the present invention 1-8 is used for smelting steel types above the Q235 series, and the test results include:

[0059] 1. The micropowder graphite recarburizer of the present invention is a columnar particle, and has the characteristics of less powder content, uniform particle size, moderate specific gravity, stable quality, convenient use, no dust, safety and environmental protection, and excellent recarburization effect;

[0060] 2. From the point of view of field use, after the micropowder graphite recarburizer of the present invention is added in the molten steel ladle, the melting time is relatively short, and it can be well melted after tapping;

[0061] 3. The carburizing effect of the micropowder graphite recarburizer of the present invention is exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com