Graphite base with protective coating layer and preparation method thereof

A technology of graphite base and protective coating, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of SiC material difficult to be completely dense, coating failure, SiC coating cracking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

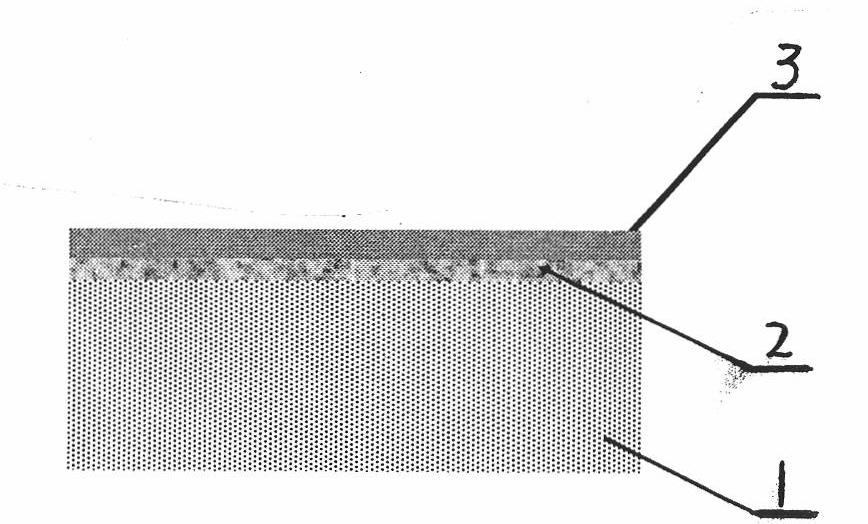

[0022] a. Put the graphite base base 1 into a reaction chamber with a vacuum of 200Pa. When the temperature of the reaction chamber rises to 1600°C, according to SiCl 4 :H 2 =1:5 volume ratio SiCl is introduced into the reaction chamber 4 Gas and H 2 Gas, using H 2 SiCl as carrier gas 4 Gas carry out, control the carrier gas H 2 The gas flow rate is 1000ml / min, the ventilation time is 0.5 hours, and the in-situ gas phase reaction penetrates a layer of primary SiC coating 2 on the graphite base substrate 1; then

[0023] b. Change to CH 3 SiCl 3 Gas and H 2 Gas, in the case of constant temperature and pressure in the reaction chamber, according to CH 3 SiCl 3 :H 2 = 1:100 volume ratio to feed CH into the reaction chamber 3 SiCl 3 Gas and H 2 Gas, using H 2 SiCl as carrier gas 4 gas carried out using H 2 Gas bubbling will CH 3 SiCl 3 Gas carry out, control the carrier gas H 2 The gas flow rate is 200ml / min, and the aeration time is 1 hour. After cracking, a la...

Embodiment 2

[0025] a. Put the graphite base base 1 into a reaction chamber with a vacuum of 5000Pa. When the temperature of the reaction chamber rises to 1300°C, according to SiCl 4 :H 2 =1:50 volume ratio SiCl is introduced into the reaction chamber 4 Gas and H 2 Gas, using H 2 SiCl as carrier gas 4 Gas carry out, control the carrier gas H 2 The gas flow rate is 200ml / min, the ventilation time is 2 hours, and the in-situ gas phase reaction penetrates a layer of primary SiC coating 2 on the graphite base substrate 1; then

[0026] b. Change to CH 3 SiCl 3 Gas and H 2 Gas, in the case of constant temperature and pressure in the reaction chamber, according to CH 3 SiCl 3 :H 2 = 1:5 volume ratio to feed CH into the reaction chamber 3 SiCl 3 Gas and H 2 Gas, using H 2 Gas as a carrier gas will CH 3 SiCl 3 Gas carry out, control the carrier gas H 2 The gas flow rate is 1000ml / min, and the ventilation time is 50 hours. After cracking, a layer of secondary SiC coating 3 is depos...

Embodiment 3

[0028] a. Put the graphite base base 1 into a reaction chamber with a vacuum of 3000Pa. When the temperature of the reaction chamber rises to 1400°C, according to SiCl 4 :H 2 =1:30 volume ratio SiCl is introduced into the reaction chamber 4 Gas and H 2 Gas, using H 2 SiCl 4Gas carry out, control the carrier gas H 2 The gas flow rate is 600ml / min, the ventilation time is 1 hour, and the in-situ gas phase reaction penetrates a layer of primary SiC coating 2 on the graphite base substrate 1; then

[0029] b. Change to CH 3 SiCl 3 Gas and H 2 Gas, in the case of constant temperature and pressure in the reaction chamber, according to CH 3 SiCl 3 :H 2 = 1:20 volume ratio to feed CH into the reaction chamber 3 SiCl 3 Gas and H 2 Gas, using H 2 gas as a carrier gas to convert CH 3 SiCl 3 Gas carry out, control the carrier gas H 2 The gas flow rate is 600ml / min, and the ventilation time is 30 hours. After cracking, a layer of secondary SiC coating 3 is deposited on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com