Gel electrolyte and preparation method thereof

A technology of gel electrolyte and iodine simple substance, which is applied in the direction of capacitor electrolyte/absorbent, circuit, photovoltaic power generation, etc., can solve the problem of low battery efficiency, and achieve the effect of high battery efficiency, low leakage and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

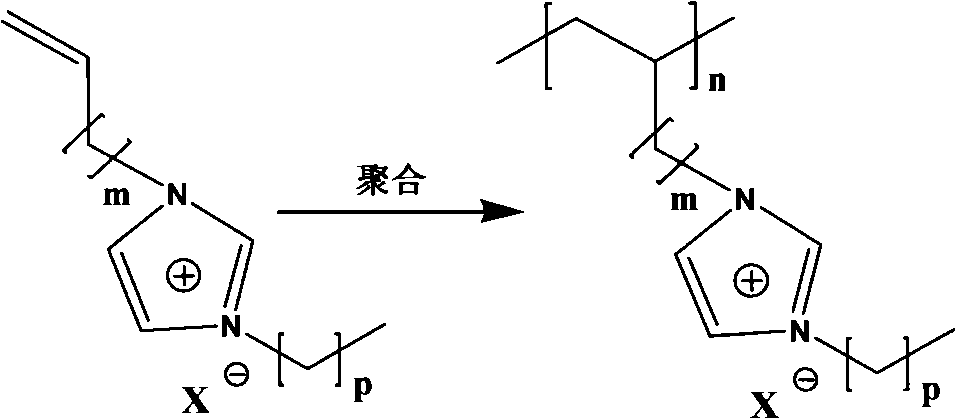

Method used

Image

Examples

Embodiment 2

[0031] 0.4g, KI0.1g, tert-butylpyridine 0.09g, iodine simple substance 0.12g, mixed and stirred for 10h at 70°C to obtain a gel electrolyte, which was dropped while hot between the photoanode dye titanium dioxide film and the Pt electrode, and further heated The gel electrolyte is completely permeated into the titanium dioxide membrane porous membrane, and then encapsulated to obtain a quasi-solid-state all-ionic liquid gel solar cell. At room temperature, use a xenon lamp to simulate sunlight with a light intensity of 100mW / cm 2 Under the conditions, the measured battery (effective area 0.16cm 2 ) The photoelectric conversion efficiency is 4.5%.

Embodiment 3

[0033] 4.5g, 0.95g, 0.25g, 0.05g NaI, 0.1g tert-butylpyridine, 0.6g elemental iodine, mixed and stirred for 1 hour at 140°C to obtain a gel electrolyte, which was dropped into between the photoanode dye titanium dioxide film and the Pt electrode while hot, and further heated The gel electrolyte is completely permeated into the titanium dioxide membrane porous membrane, and then encapsulated to obtain a quasi-solid-state all-ionic liquid gel solar cell. At room temperature, use a xenon lamp to simulate sunlight with a light intensity of 100mW / cm 2 Under the conditions, the measured battery (effective area 0.16cm 2 ) The photoelectric conversion efficiency is 3.2%.

Embodiment 4

[0035] 0.075g, 0.6g, 0.6g, LiI0.3g, 0.3g tert-butylpyridine, 0.01g elemental iodine, mixed and stirred for 20h at 50°C to obtain a gel electrolyte, which was dropped into between the photoanode dye titanium dioxide film and the Pt electrode while hot, and further heated The gel electrolyte is completely permeated into the titanium dioxide membrane porous membrane, and then encapsulated to obtain a quasi-solid-state all-ionic liquid gel solar cell. At room temperature, use a xenon lamp to simulate sunlight with a light intensity of 100mW / cm 2 Under the conditions, the measured battery (effective area 0.16cm 2 ) The photoelectric conversion efficiency is 6.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com