Method for biologically removing sulfureted hydrogen from marsh gas

A biological method, hydrogen sulfide technology, applied in the direction of chemical instruments and methods, separation methods, gas fuel, etc., can solve the problems of secondary pollution, complex regeneration process, high cost, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

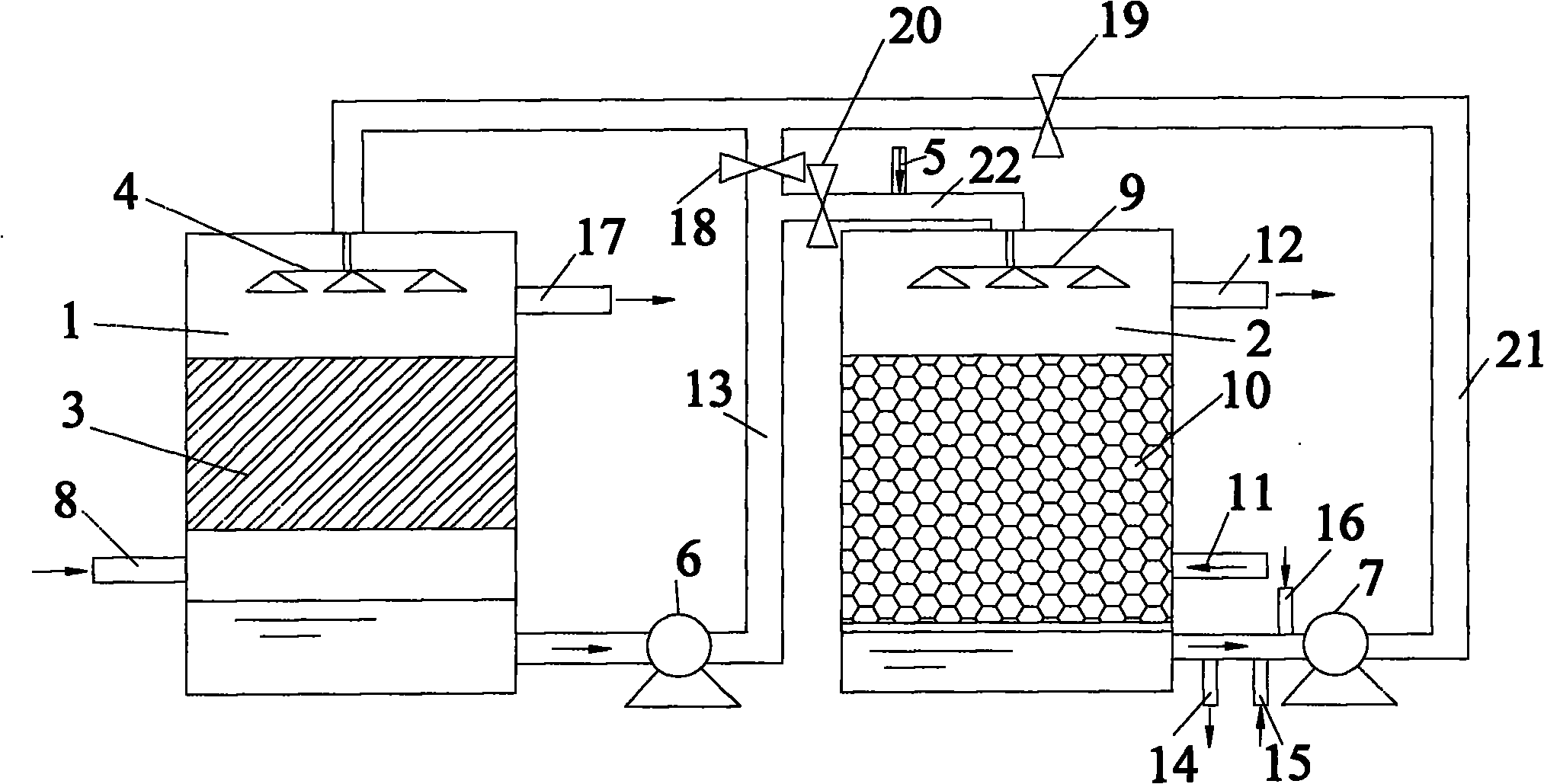

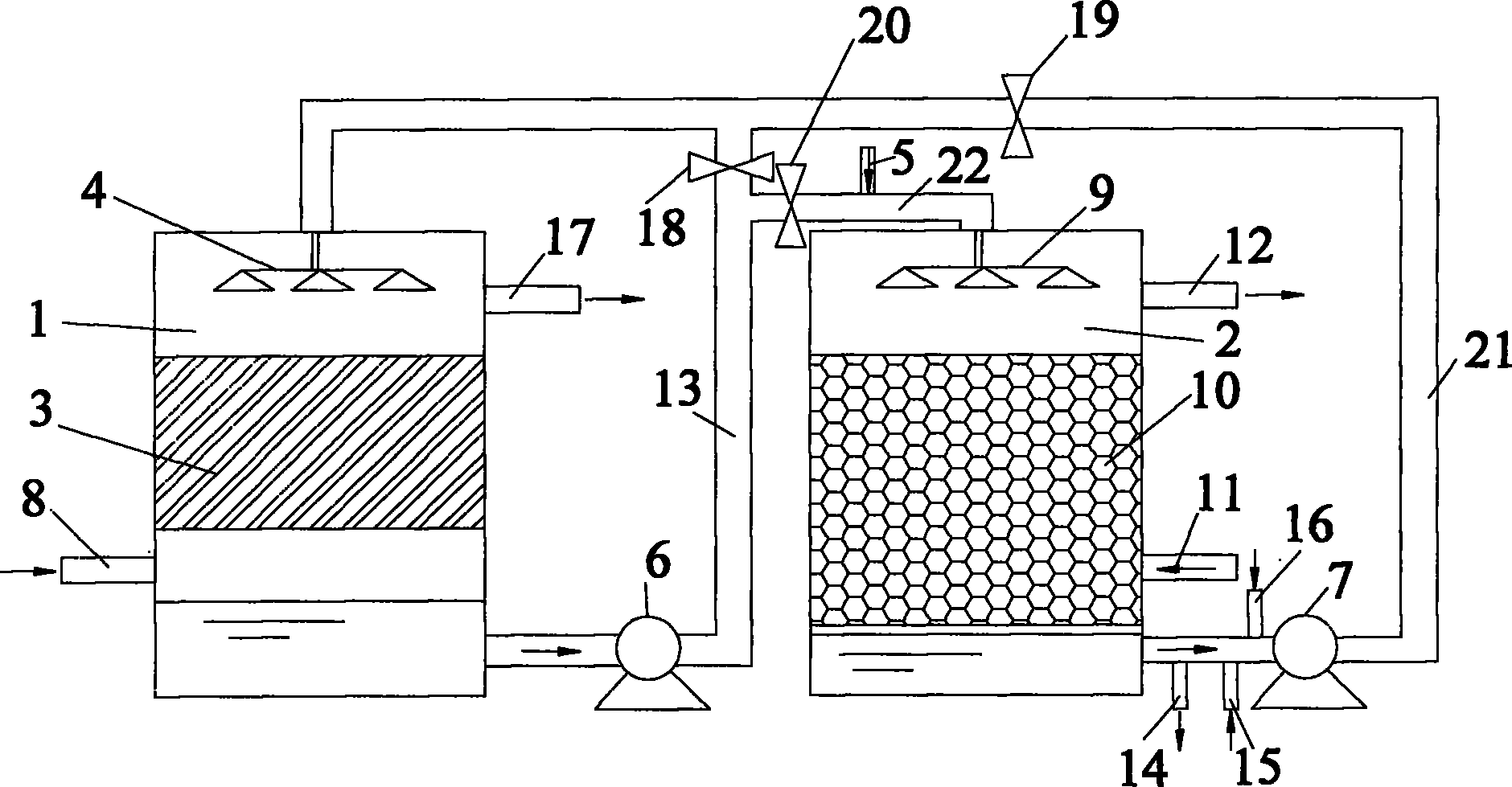

Method used

Image

Examples

Embodiment 1

[0020] In this embodiment, the packed spray absorption tower 1 has a height of 1 m, a diameter of 0.25 m, and a built-in polypropylene filler 3 with a height of about 0.5 m. A spray device 4 is installed on the top of the absorption tower. h 2 Biogas with an S content of 300ppm enters the tower through the biogas inlet pipe 8 in the middle of the absorption tower 1, and diffuses to the top of the tower through the packing 3 of the absorption tower 1 under the action of pressure. The residence time of the biogas in the absorption tower 1 is 2 minutes. The spray 4 at the top of the tower will contain Na 2 CO 3 The spray liquid with NaOH is sprayed on the filler 3 of the packing layer, the total volume of the spray liquid is 10L, and the biogas reacts with the spray liquid in the process of upward diffusion as follows:

[0021] h 2 S+OH-=HS-+H 2 O (1)

[0022] h 2 S+CO 3 2- =HS-+HCO 3 - (2)

[0023] CO 2 +OH-=HCO 3 - (3)

[0024] HCO ...

Embodiment 2

[0031] Embodiment 2: the difference between this embodiment and embodiment 1 is: the residence time of the biogas in the absorption tower 1 is 1.5min, and the H in the biogas in the biogas outlet pipe 17 of the absorption tower 1 2 The concentration of S is 21ppm, and the purification rate is 93%; 2 78% of the spraying liquid of S is sent back to the absorption tower 1 for circulating spraying, and the other 22% of the spraying liquid is mixed with 6ml / h nutrient solution and enters the biological filter tower 2; the residence time of the mixed liquid in the biological filter tower 2 for 30min.

Embodiment 3

[0032] Embodiment 3: the difference between this embodiment and embodiment 1 is: the residence time of the biogas in the absorption tower 1 is 1min; in the biogas in the biogas outlet pipe 17 of the absorption tower 1, H 2The concentration of S is 24ppm, and the purification rate is 92%; 2 70% of the spraying liquid of S is transported back to the absorption tower 1 for circulating spraying, and the other 30% of the spraying liquid is mixed with 7.5ml / h nutrient solution and enters the biological filter tower 2; The residence time is 60min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com