Environment-friendly nano ceramic film coating with self heat radiating function and preparation method thereof

A ceramic film coating, an environmentally friendly technology, applied in the direction of coating, can solve the problems of poor heat resistance, heat dissipation, passenger health threat, etc., and achieve the effects of good weather resistance, high thermal conductivity and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

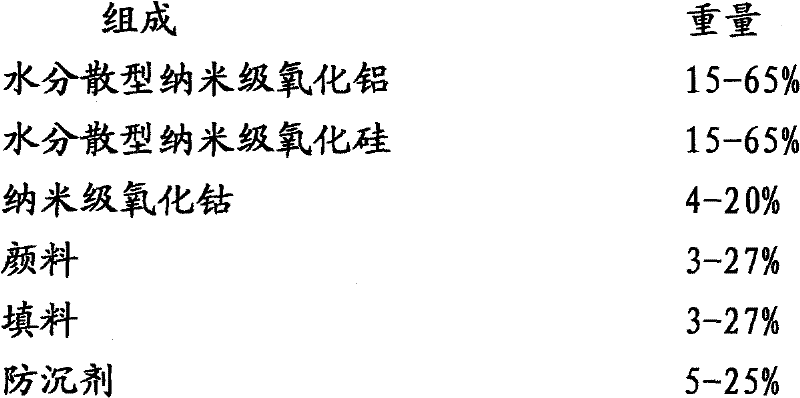

[0027] The environment-friendly nano-ceramic film coating with self-radiating function of the present invention can be formed according to the following formula:

[0028]

[0029]

[0030] These components add up to a total of 1000 kg.

[0031] The aluminum sol is water-dispersed nano-scale alumina, and its particle size can be selected as 15nm.

[0032] The silica sol is water-dispersed nano-scale silicon oxide with a particle size of 20nm.

[0033] The cobalt oxide is nano-scale cobalt oxide, and its particle size is 30nm.

[0034] The pigment can be copper chrome black, which has excellent chemical corrosion resistance, outdoor weather resistance, heat stability, light resistance, and has no permeability and no migration.

[0035] The filler can be nano-sized microcrystalline powder silica, the whiskers have small particle size and strong dispersibility, which helps to achieve the purpose of uniform mixing in the coating.

[0036] The anti-sedimentation agent can b...

specific Embodiment 2

[0037] The environment-friendly nano-ceramic film coating with self-radiating function of the present invention can be formed according to the following formula:

[0038]

[0039] These components add up to a total of 1000 kg.

[0040] The aluminum sol is water-dispersed nano-scale alumina, and its particle size can be selected as 25nm.

[0041] The silica sol is water-dispersed nano-scale silicon oxide with a particle size of 15nm.

[0042] The cobalt oxide is nano-scale cobalt oxide, and its particle size is 20nm.

[0043] The pigment can be titanium dioxide, which has strong hiding power, uniform and fine particles, easy dispersion and stable performance.

[0044] The filler can be alumina, which is a nano-scale powder with strong dispersion and easy to achieve uniform mixing in the coating. At the same time, because of its own nano-effect, it is beneficial to optimize the performance of the coating.

[0045] Among them, the anti-sedimentation agent can choose lithium...

specific Embodiment 3

[0046] The environment-friendly nano-ceramic film coating with self-radiating function of the present invention can be formed according to the following formula:

[0047]

[0048] These components add up to a total of 1000 kg.

[0049] The aluminum sol is water-dispersed nano-scale alumina, and its particle size can be selected as 35nm.

[0050] The silica sol is water-dispersed nano-scale silicon oxide with a particle size of 25nm.

[0051] The cobalt oxide is nano-scale cobalt oxide, and its particle size is 10nm.

[0052] One of the pigments, optional cobalt blue, has excellent hiding power, color transparency and high tinting strength, thermal stability, light fastness, and high light reflectivity.

[0053] The filler may be potassium titanate whiskers, which are highly dispersible and help to achieve the purpose of homogenization and mixing in the coating. At the same time, because of the strength of the whiskers themselves, it is beneficial to strengthen the cohesio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com