Zirconia mesoporous fiber and preparation method thereof

A technology of zirconia mesoporous and zirconium mesoporous, which is applied in fiber treatment, spinning solution preparation, textile and paper making, etc., to achieve the effects of good continuity, mature preparation means and complete morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (1) Preparation solution: ZrOCl 2 ·8H 2 O 0.018mol and Si(OC 2 h 5 ) 4 0.002mol, (molar ratio Si(OC 2 h 5 ) 4 : ZrOCl 2 ·8H 2 O=1:9) is dissolved in dehydrated alcohol, is mixed with the solution that mass concentration is 25%, then adds the ethanol solution (mass concentration is 25%) of 2.5g block copolymer template agent P123, obtains mixed solution I; Room temperature down, press CH 3 COOK: ZrOCl 2 ·8H 2 Potassium acetate (CH 3 COOK, 0.018mol) and dissolved in absolute ethanol to prepare a mass concentration of 15% potassium acetate ethanol solution II. This solution II was slowly added to the above mixed solution I. Continue to stir, and after separating the generated white precipitate (KCl), a clear precursor sol is obtained.

[0045] (2) Distill and concentrate the obtained precursor sol under reduced pressure at 40° C. to obtain a sol spinning solution with a viscosity of 40 Pa·s.

[0046] (3) The sol was placed statically for 2 hours, and the pre...

Embodiment 2

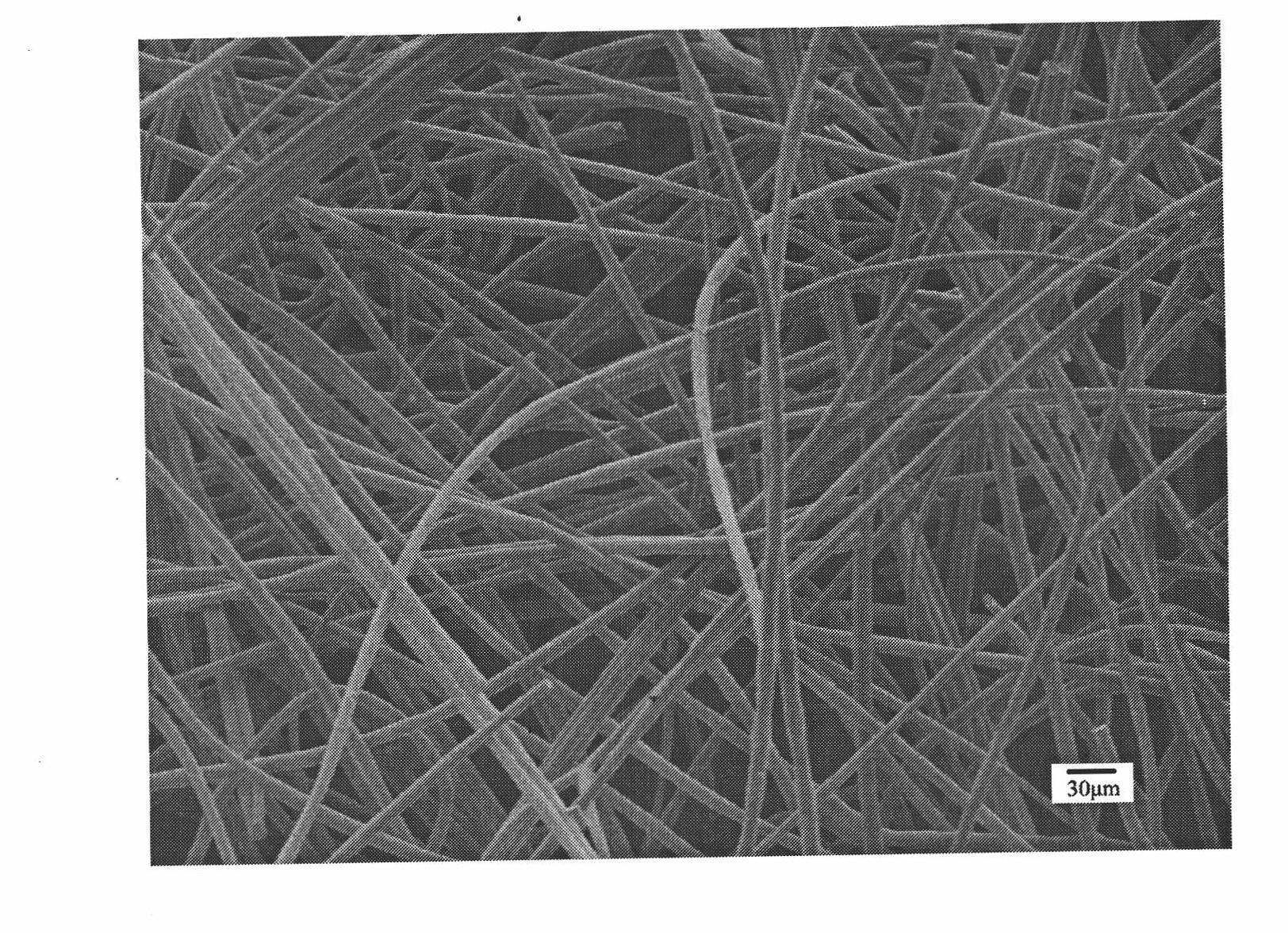

[0049] As described in Example 1, the difference is that the molar ratio of Si(OC 2 h 5 ) 4 : ZrOCl 2 ·8H 2 O=1:4, CH 3 COOK: ZrOCl 2 ·8H 2 O=1:1 add ZrOCl 2 ·8H 2 O, Si(OC 2 h 5 ) 4 and CH 3 COOK. It can be obtained with a diameter of 5-10μm, a pore diameter of about 5nm, and a specific surface area of 114m 2 g -1 , the pore volume is 0.137cm 3 g -1 zirconia mesoporous fibers.

Embodiment 3

[0051] As described in Example 1, the difference is that the molar ratio of Si(OC 2 h 5 ) 4 : ZrOCl 2 ·8H 2 O=3:7, CH 3 COOK: ZrOCl 2 ·8H 2 O=1:1 add ZrOCl 2 ·8H 2 O, Si(OC 2 h 5 ) 4 and CH 3 COOK. It can be obtained with a diameter of 5-10μm, a pore diameter of about 5nm, and a specific surface area of 146m 2 g -1 , the pore volume is 0.164cm 3 g -1 zirconia mesoporous fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com