Cleaning agent

A cleaning and gelling agent technology, applied in cleaning methods and utensils, chemistry, cleaning methods using liquids, etc., can solve problems such as insufficient effect and ineffective cleaning agent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

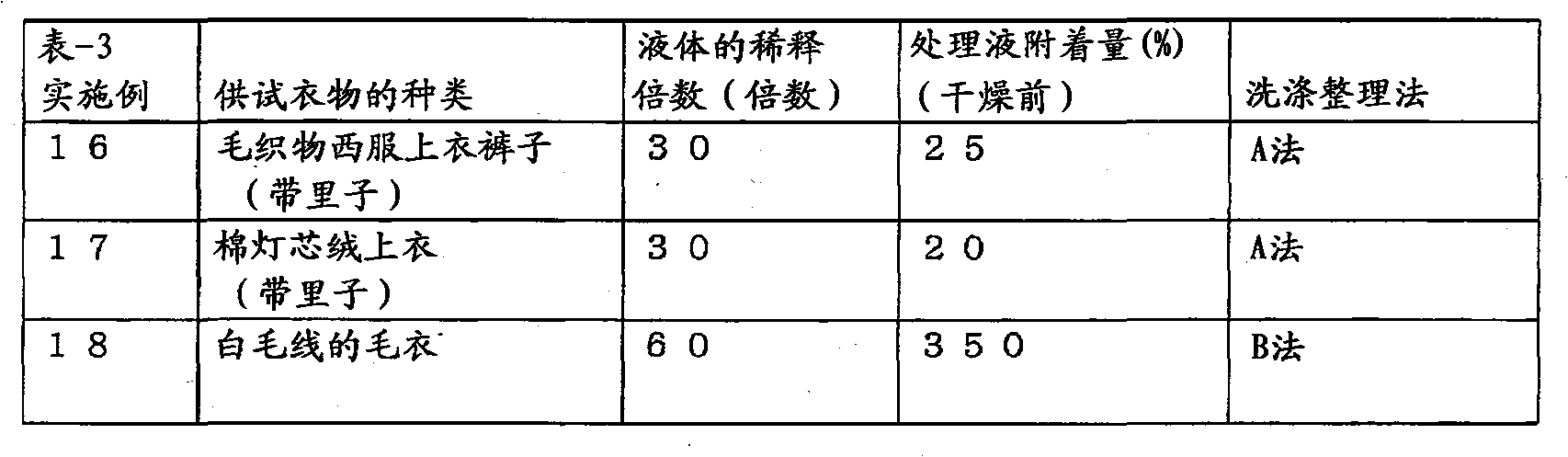

[0134] The present invention is further described in detail with examples below. % in the examples means % by weight unless otherwise specified.

[0135]

[0136] The cleaning agent and the cleaning method of the present invention are to spray the cleaning agent of the present invention on the airflow in the pipes, chimneys, and ventilation passages that discharge polluted air from various enterprise premises and facilities, and in the spray chambers provided between them. , so that the molecular to aerosol air pollutants settle in the lower part until the exhaust, and after separation, the waste liquid is treated and the clean air is discharged into the atmosphere. It can also be used in various production plants, processing plants or hospitals, nursing care In the exhaust of facilities, public facilities, high-rise buildings, etc.

reference example 1

[0138] In a certain asphalt recycling factory, there is a device that strips and heats asphalt that has deteriorated over time and is used for road paving 10 years ago, and mixes almost the same amount of new asphalt while heating, and softens the asphalt. In the state, it is transported to the road paving site. During the operation of the factory, in order to deodorize and eliminate the black smoke with a strong stench produced by the device, a horizontal water spray cleaner was installed 2.5m above the ground surface. After cleaning, it was cleaned from a height of about 25m The chimney exhausts into the atmosphere, but it has no effect at all. There are black tar-like substances settled and polluted on the flat land around the factory and tens of meters around the forest. Residents in the area have continued to complain.

Embodiment 1

[0140] From the entrance hole of about 30cm in diameter in about 3m under the high 25m chimney of distance reference example 1 factory, made by containing amphoteric macromolecule compound 0.0006%, m=3, n=3, p=12 in formula (1) Poly(hexamethylene biguanide) hydrochloride 0.001%, glycine 0.001%, diisopropanolamine 0.001% aqueous solution to form a cleaning agent, the amphoteric macromolecular compound is acrylic acid 20 mol% and acrylamide 80 Mole % average molecular weight 1.9 x 10 7A compound having a composition such that 20 mol % of dimethylaminomethacrylamide groups were introduced into 1 kg of the copolymer. This cleaning agent is used as a spray liquid, using a two-fluid sprayer with an average particle diameter of 15 μm and a spray angle of 15 degrees at a distance of 30 cm from the front end of the nozzle, at a rate of about 2 minutes and 120 ml / minute, in parallel with the air flow. Fluidly insert the nozzle at approximately the center of the chimney and spray. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com