Acipimox push-pull osmotic pump controlled release tablet and preparation method thereof

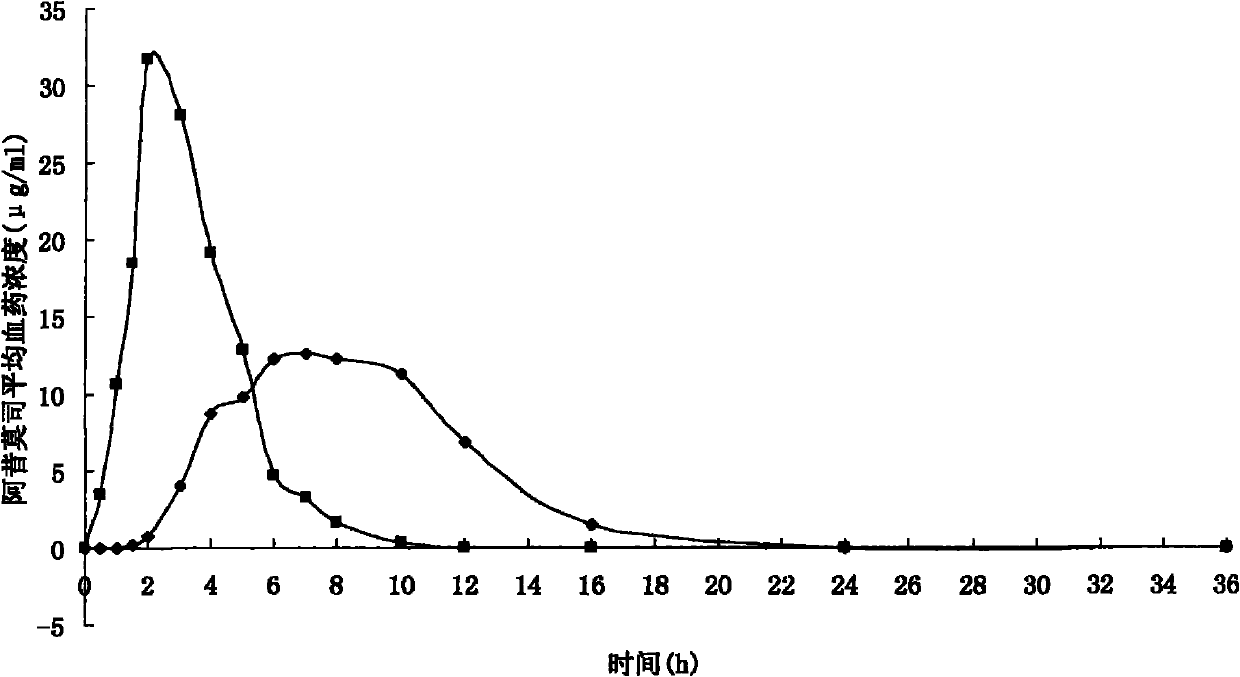

A technology of osmotic pump controlled release and acyclolimus, which is applied in the field of acyclomus double-layer osmotic pump controlled release tablet and its preparation, and achieves the effect of overcoming the frequent taking and maintaining blood drug concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

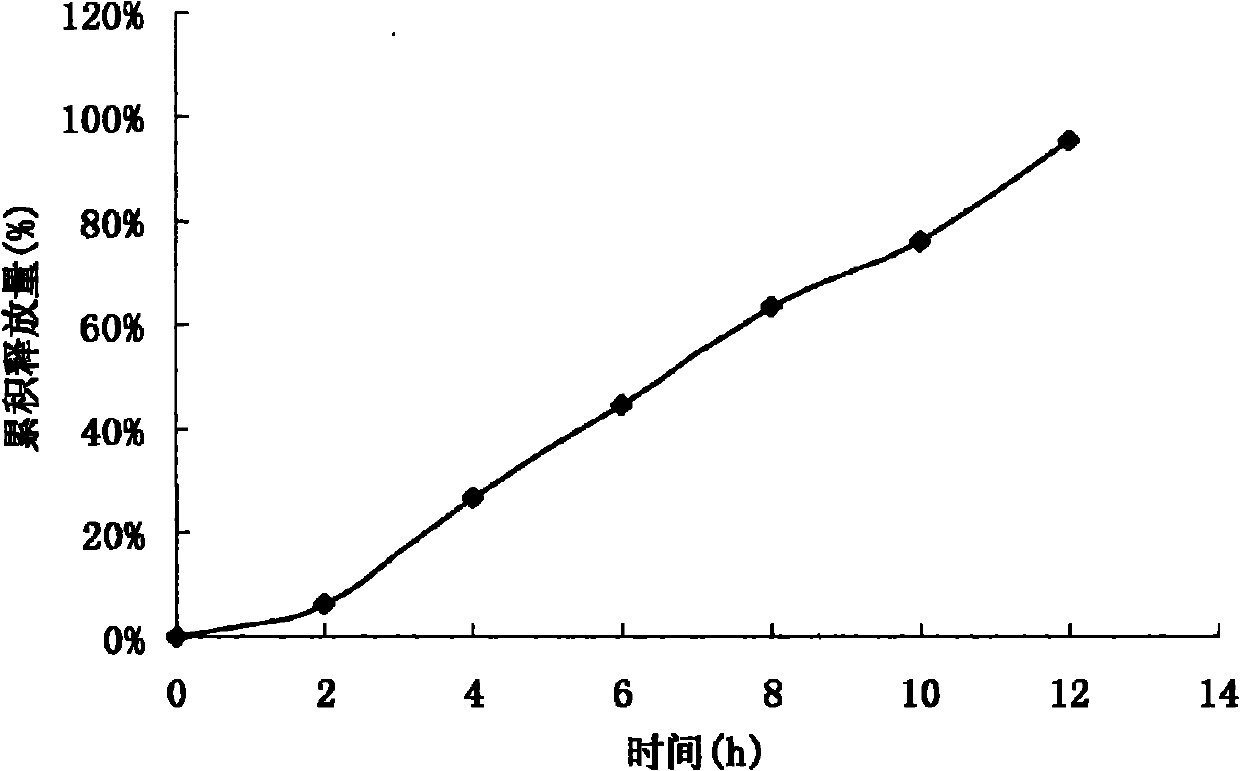

Examples

Embodiment 1

[0025] Tablet prescription:

[0026] Drug-containing layer

[0027] Acipimox 250mg

[0028] Polyoxyethylene 200mg

[0029] Mannitol 20mg

[0031] Anhydrous ethanol amount

[0032] booster layer

[0033] Sodium Alginate 90mg

[0034] Sucrose 15mg

[0035] Semi-permeable coating film prescription:

[0036] Cellulose acetate 18g

[0037] Macrogol 4000 4g

[0038] Solvent prescription for dissolving film coating material:

[0039] Acetone 1000mL

[0040] Distilled water 20mL

[0041] Preparation Process:

[0042] Pass the prescribed amount of medicine, polyoxyethylene with a molecular weight of 200,000, and mannitol through an 80-mesh sieve, mix evenly, use absolute ethanol as a binder to make a soft material, and granulate with a 20-mesh sieve. After the wet granules are dried, sieve through a 18-mesh sieve Granules, dry granules and lubricants are...

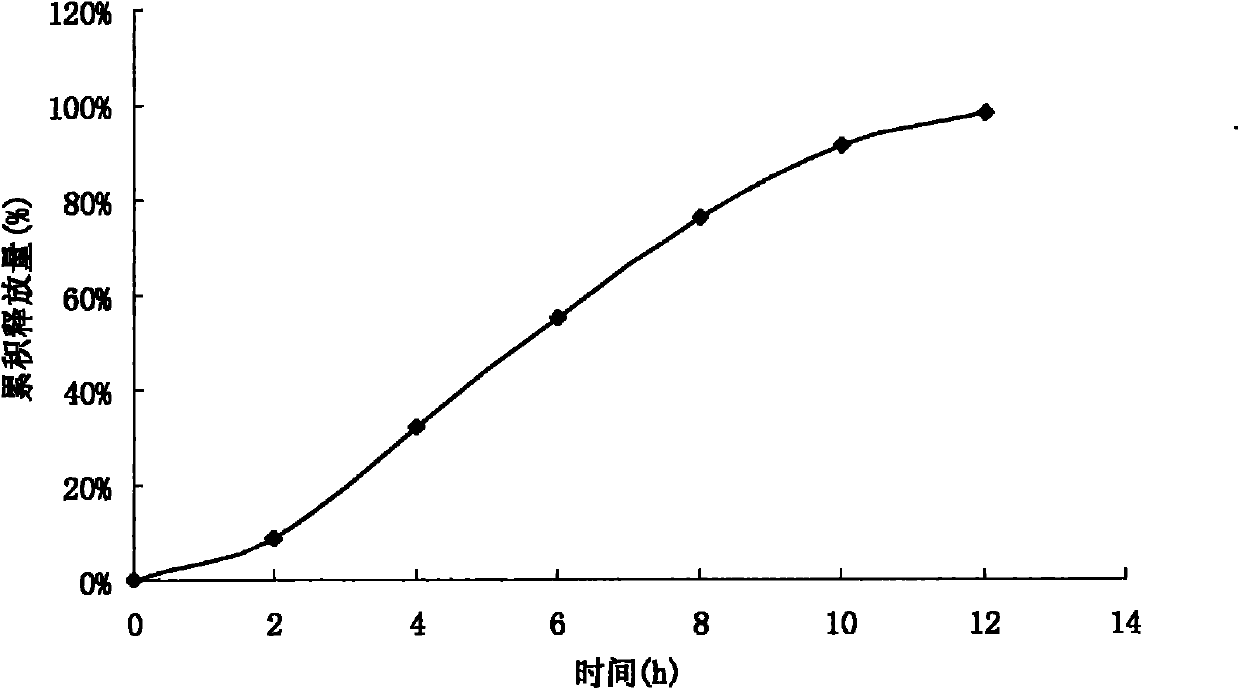

Embodiment 2

[0044] Tablet prescription:

[0045] Drug-containing layer

[0046] Acipimox 250mg

[0047] Gum Arabic 300mg

[0050] 95% ethanol appropriate amount

[0051] booster layer

[0052] Polyoxyethylene PEO WSR301 100mg

[0053] Lactose 10mg

[0054] Semi-permeable coating film prescription:

[0055] Ethyl cellulose 20g

[0056] Macrogol 6000 4g

[0057] Solvent prescription for dissolving film coating material:

[0058] Acetone 500mL

[0059]Distilled water 30mL

[0060] Preparation Process:

[0061] Pass the prescribed amount of medicine, gum arabic, and sodium chloride through an 80-mesh sieve, mix evenly, use 95% ethanol as a binder to make a soft material, granulate with a 20-mesh sieve, and after the wet granules are dried, granulate with an 18-mesh sieve and dry The drug layer is obtained after the granules and lubricant a...

Embodiment 3

[0063] Tablet prescription:

[0064] Drug-containing layer

[0065] Acipimox 250mg

[0066] Polyoxyethylene 150mg

[0067] Lactose 10mg

[0068] Micronized silica gel 3mg

[0069] Anhydrous ethanol amount

[0070] booster layer

[0071] Polyoxyethylene 130mg

[0073] Semi-permeable coating film prescription:

[0074] Cellulose acetate 12g

[0075] Acrylic 8

[0076] Macrogol 1500 5g

[0077] Solvent prescription for dissolving film coating material:

[0078] Acetone 1000mL

[0079] Distilled water 30mL

[0080] Preparation Process:

[0081] Pass the prescribed amount of medicine, polyoxyethylene with a molecular weight of 500,000, and lactose through a 80-mesh sieve, mix evenly, use absolute ethanol as a binder to make a soft material, granulate with a 20-mesh sieve, and dry the wet granules, then sieve through a 18-mesh sieve Granules, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com