Preparation process of N,N-dimethylcyclohexylamine

A technology for the preparation of dimethylcyclohexylamine, which is applied to the preparation of amino compounds, the preparation of organic compounds, organic chemistry, etc., can solve the problems of high pressure and high production cost, and achieve low production cost, high product yield, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Preparation of N, N-dimethylcyclohexylamine: In a 0.5 liter reactor equipped with an electric stirrer, reflux condensing device, and feeding funnel device, 50 grams of cyclohexylamine were added, and 135 grams of cyclohexylamine were added dropwise under stirring. 85% formic acid solution, stirred at 300 rpm for 0.5 hour, added 90 g of 36% formaldehyde solution, reacted at 90°C for 3 hours, cooled the reaction mixture, and brought it to room temperature, added an appropriate amount of sodium hydroxide solution to alkalize, water After steam distillation, the fraction at 160-163°C was collected, which was N,N-dimethylcyclohexylamine, and the yield was 82%.

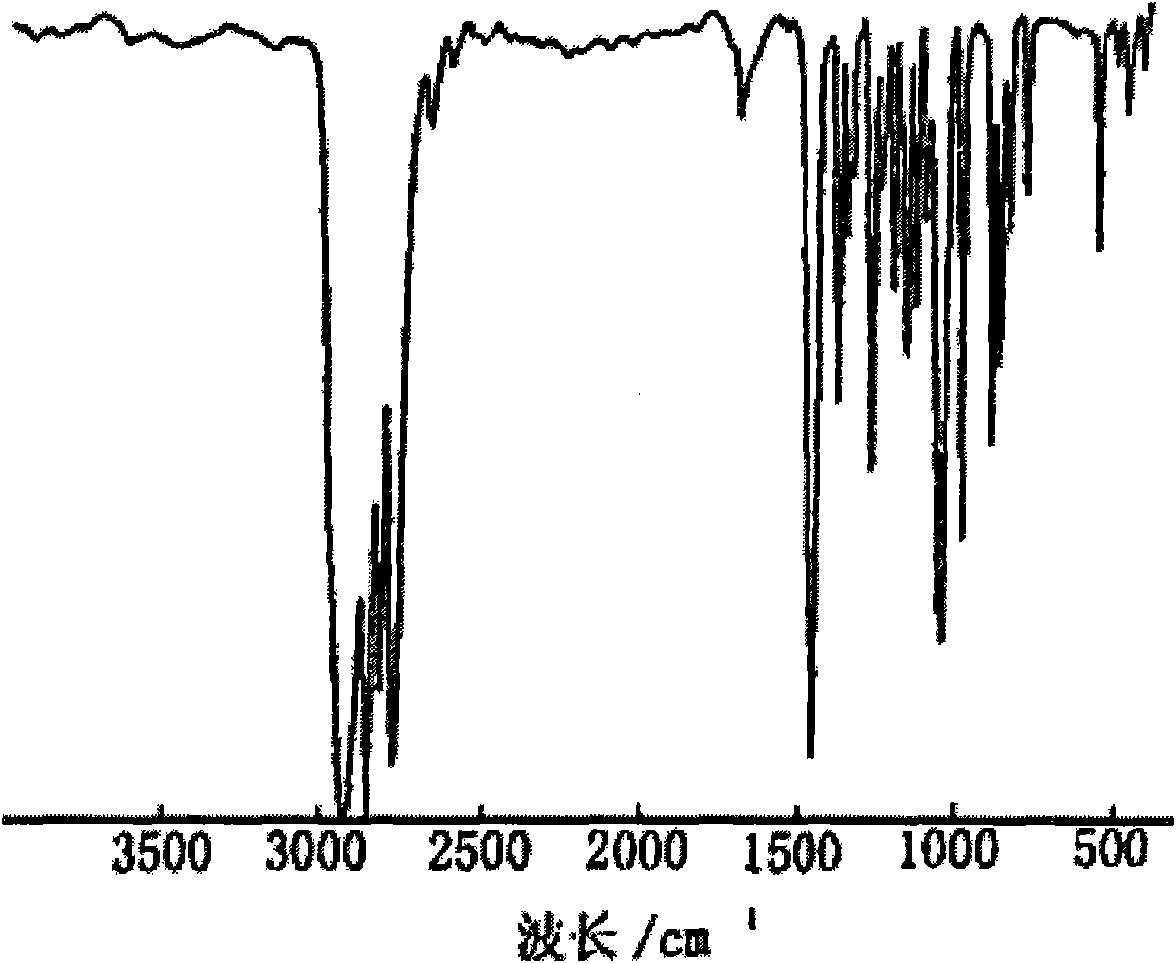

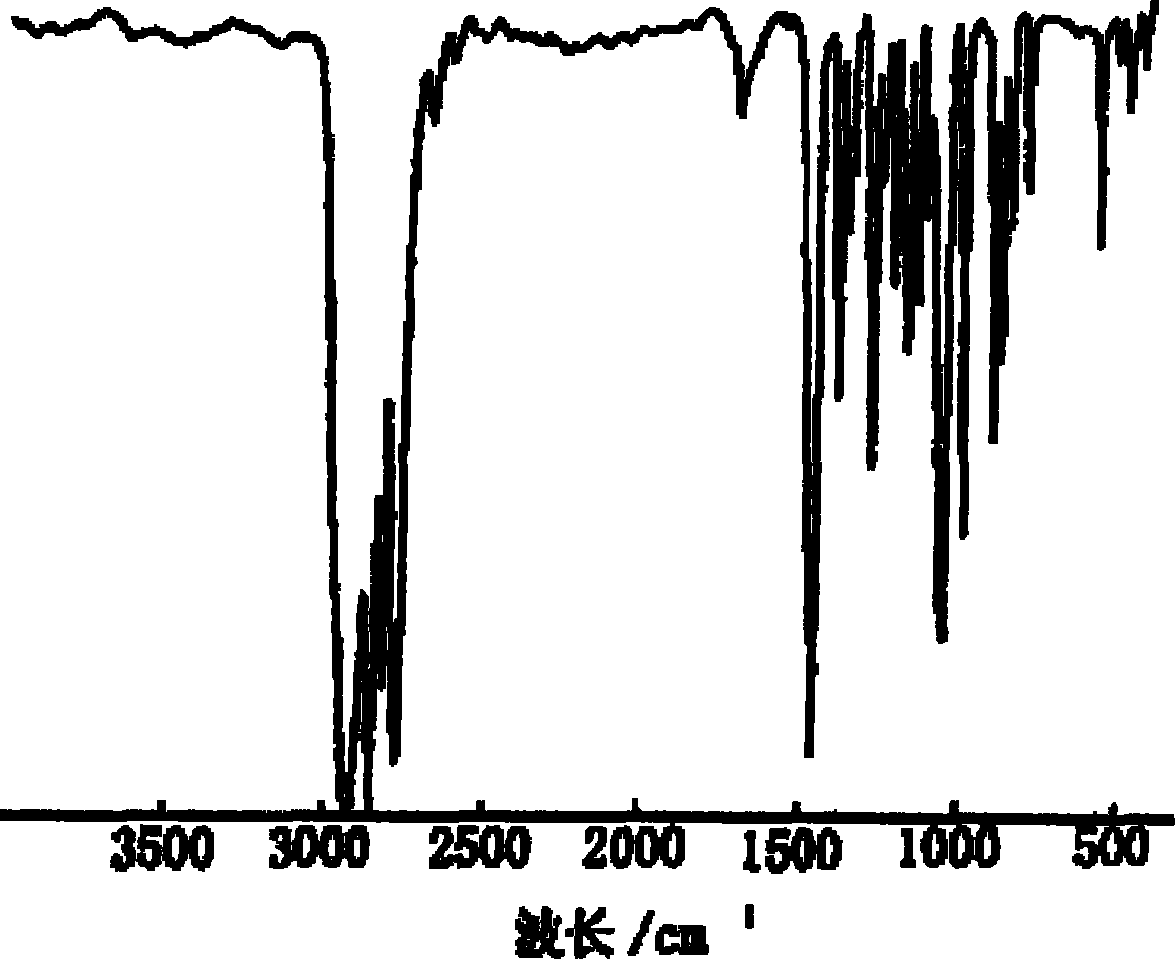

[0014] Utilize FTIRNicolet-460 infrared spectrometer (liquid film method) to product analysis, draw conclusion as follows: figure 1 Shown, IR(v / cm -1 ): 2926, 2852, 2825, 2775 are antisymmetric and symmetric stretching vibration absorption of C-H; 1450, 1376 are -CH respectively 3 Antisymmetric and sy...

Embodiment 2

[0015] Embodiment 2: prepare N, N-dimethylcyclohexylamine: in the 1 liter reactor that electric stirrer, reflux condensing device, feeding funnel device are housed, add 110 grams of cyclohexylamine, add dropwise 270 grams under stirring 85% formic acid solution, stirred at 500 rpm for 1 hour, added 180 g of 36% formaldehyde solution, reacted for 4 hours at 95°C, cooled the reaction mixture, and brought it to room temperature, added an appropriate amount of sodium hydroxide solution to alkalize, water After steam distillation, the fraction at 160-163°C was collected, which was N,N-dimethylcyclohexylamine, and the yield was 84%.

Embodiment 3

[0016] Embodiment 3: prepare N, N-dimethylcyclohexylamine: in 10 liters of reactors that electric stirrer, reflux condensing device, feeding funnel device are housed, add 1100 grams of cyclohexylamines, add dropwise 2700 grams under stirring 85% formic acid solution was stirred for 1.5 hours at a speed of 500 rev / s, and 1800 g of 36% formaldehyde solution was added, and reacted for 5 hours at 98° C., and the reaction mixture was cooled to room temperature, and an appropriate amount of sodium hydroxide solution was added to make it alkaline, and water After steam distillation, the fraction at 160-163°C is collected, which is N,N-dimethylcyclohexylamine, and the yield is 86%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com