Compound microbial agent and production method and application thereof

A technology of compound microbial inoculum and Enterococcus faecalis, applied in application, animal feed, animal feed, etc., can solve the problems of single function of microbial feed additive, single metabolite composition, difficult product quality control, etc., and achieve great practicality and promotion. value, improve economic efficiency, and improve the effect of disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] The preparation method of the composite microbial bacterial agent: count the Candida utilis, Enterococcus faecalis, Lactobacillus acidophilus and Bacillus subtilis in parts by weight after the propagation and cultivation: Enterococcus faecalis: Lactobacillus acidophilus : Bacillus subtilis==1: 1: 1: 1, after mixing the above-mentioned strains, 10% by mass percentage is fermented at a constant temperature in the culture medium, and stirred while passing oxygen, the initial temperature of the culture is 28 ℃ for 24 hours, Cultivate at 30°C for 24 hours and at 35°C for 12 hours until the fermentation culture reaches a pH value of 2.5.

[0012] The medium is 1g of agar, 1g of beef extract, 2.5g of yeast extract, 35g of sucrose, 1.5g of defoamer (commercially available product, purchased from Meichen Group Co., Ltd. in this embodiment), 1g of peptone, and distilled water is added to 1000ml pH3.0~5.0, autoclave at 110~130℃. The yeast extract is yeast extract powder (commerci...

Embodiment 2

[0025] The preparation method of embodiment 2 composite microbial bacterial agents: the Candida utilis, Enterococcus faecalis, Lactobacillus acidophilus and Bacillus subtilis after the proliferation culture are calculated in parts by weight. Candida utilis: Enterococcus faecalis: Enterococcus faecalis Lactobacillus acidum: Bacillus subtilis == 1:2:2:1, mix the above strains and ferment in the culture medium at a constant temperature of 15% by mass, and stir while passing oxygen. The initial temperature of the culture is 28°C. 24 hours, culture at 30°C for 24 hours, and culture at 35°C for 12 hours, until the fermentation culture reaches a pH value of 3. The culture medium is 0.5 g of agar, 0.5 g of beef extract, 2 g of yeast extract, 30 g of sucrose, 3.0 g of defoamer, 0.5 g of peptone, and 1000 mL of distilled water. pH3.0~5.0, autoclave at 110~130℃. The yeast extract is yeast extract powder.

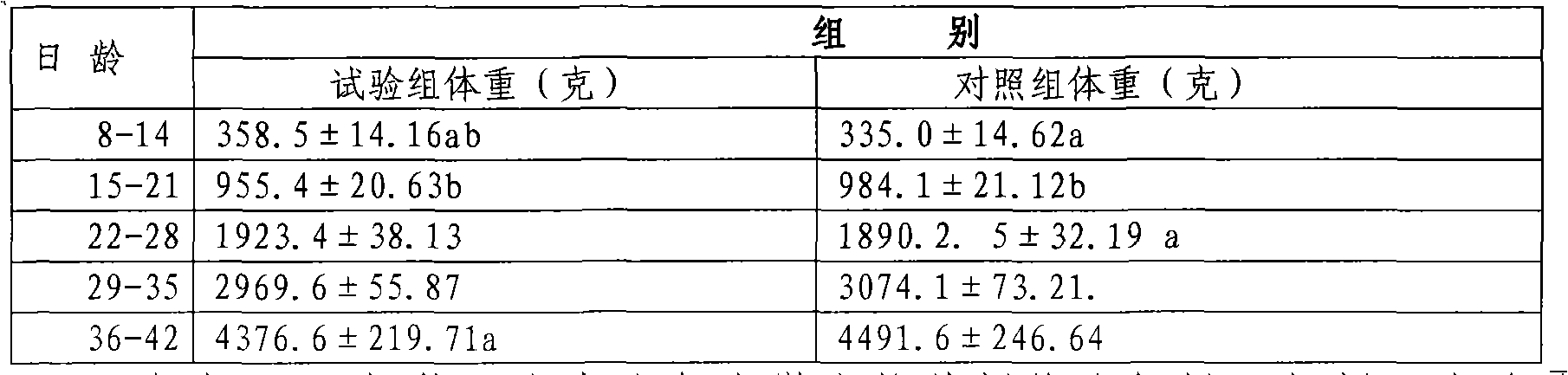

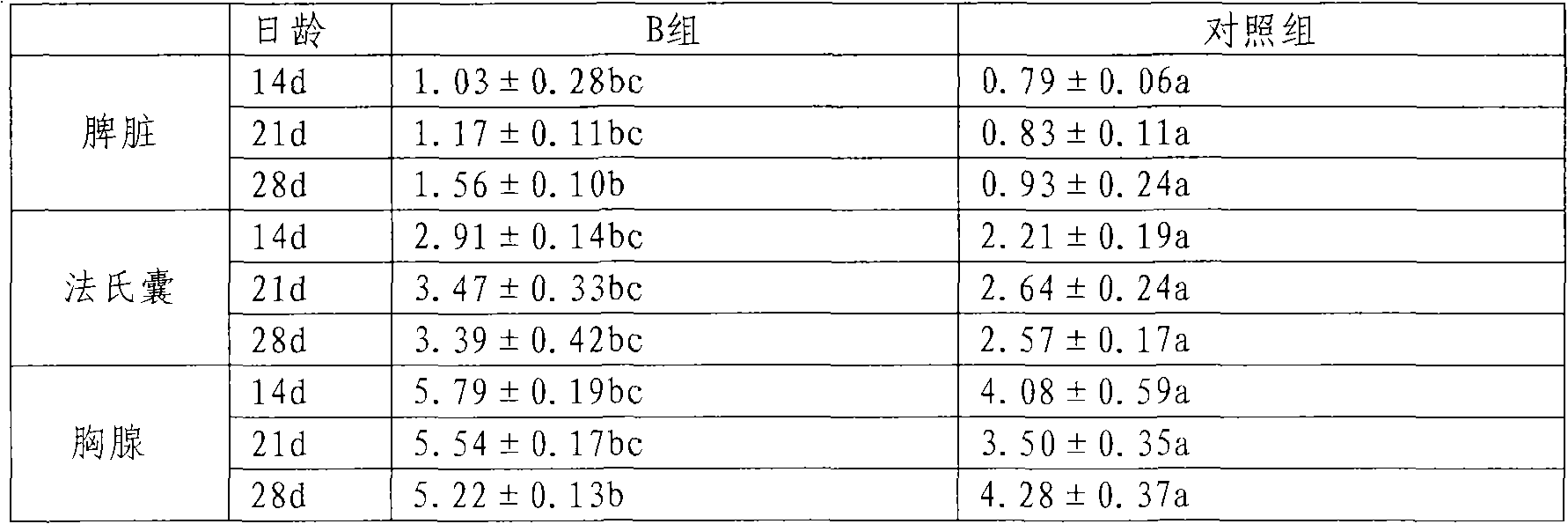

[0026] With above-mentioned compound microbial inoculum as the additive of raisi...

Embodiment 3

[0032] The preparation method of the composite microbial bacterial agent: count the Candida utilis, Enterococcus faecalis, Lactobacillus acidophilus and Bacillus subtilis in parts by weight after the propagation and cultivation: Enterococcus faecalis: Lactobacillus acidophilus : Bacillus subtilis==3: 1: 1: 1, the above-mentioned strains are mixed and fermented at a constant temperature in the culture medium by 12% by mass percentage, and stirred while passing oxygen, and the initial temperature of the culture is 28° C. for 24 hours. Cultivate at 30°C for 24 hours and at 35°C for 12 hours until the fermentation culture reaches a pH value of 3.5. The culture medium is 1.5g of agar, 1.5g of beef extract, 2g of yeast extract, 45g of sucrose, 2g of defoamer, 1.5g of peptone, and 1000mL of distilled water. pH3.0~5.0, autoclave at 110~130℃. The yeast extract is yeast extract powder.

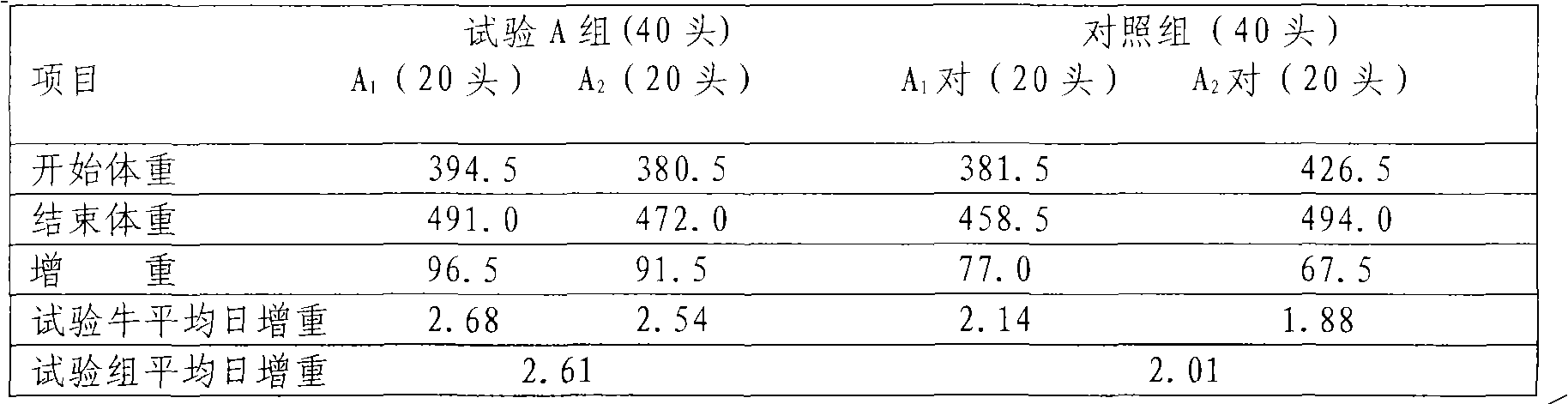

[0033] The above-mentioned compound microbial inoculum was used as an additive for raising cattle,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com