Preparation method of sodium bismuth titanate-based ferroelectric film

A bismuth sodium titanate and ferroelectric thin film technology, applied in the direction of layered products, etc., can solve the problems of no effective optimization of performance, poor film formation and insufficient performance of bismuth sodium titanate-based thin films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

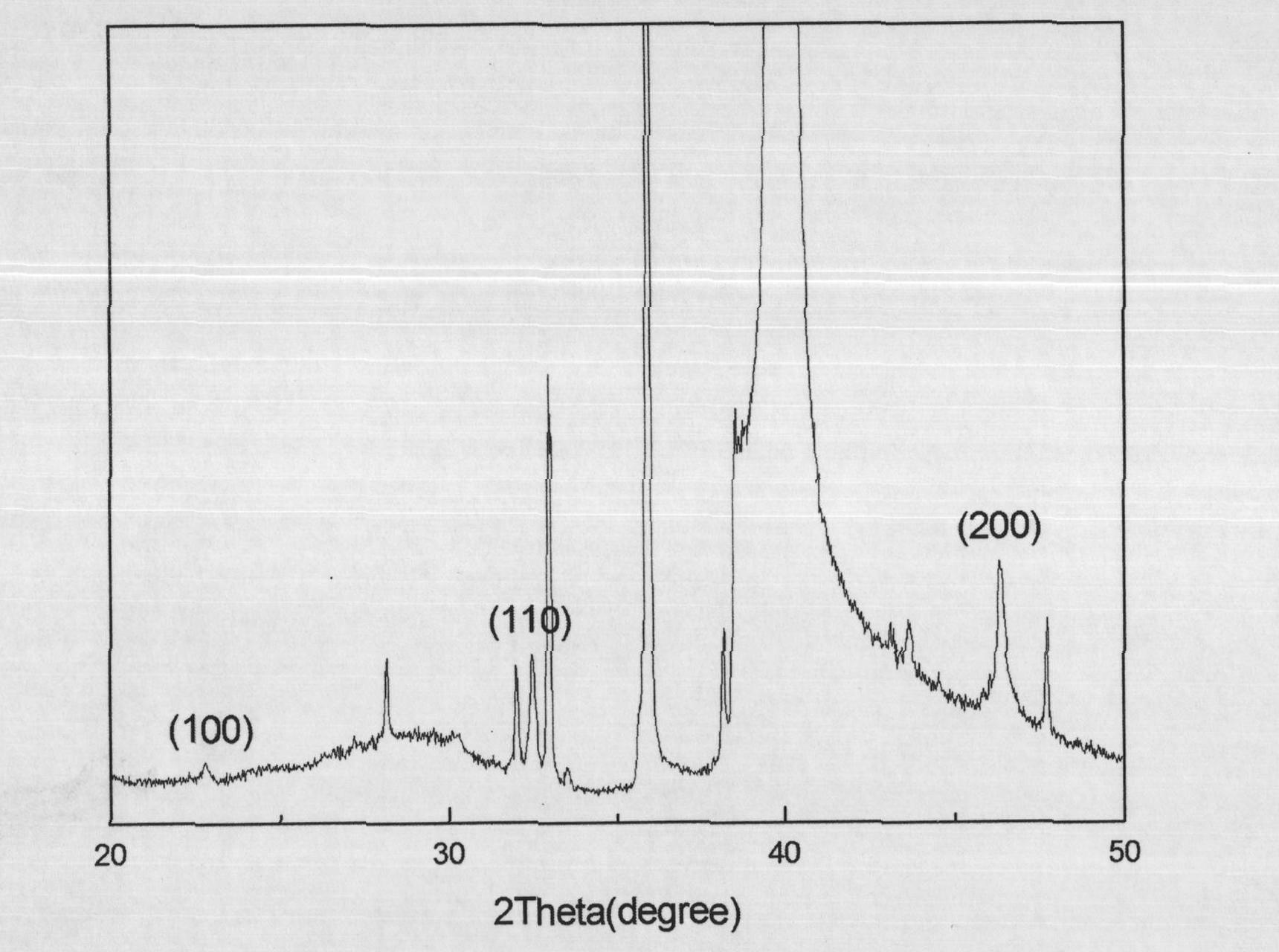

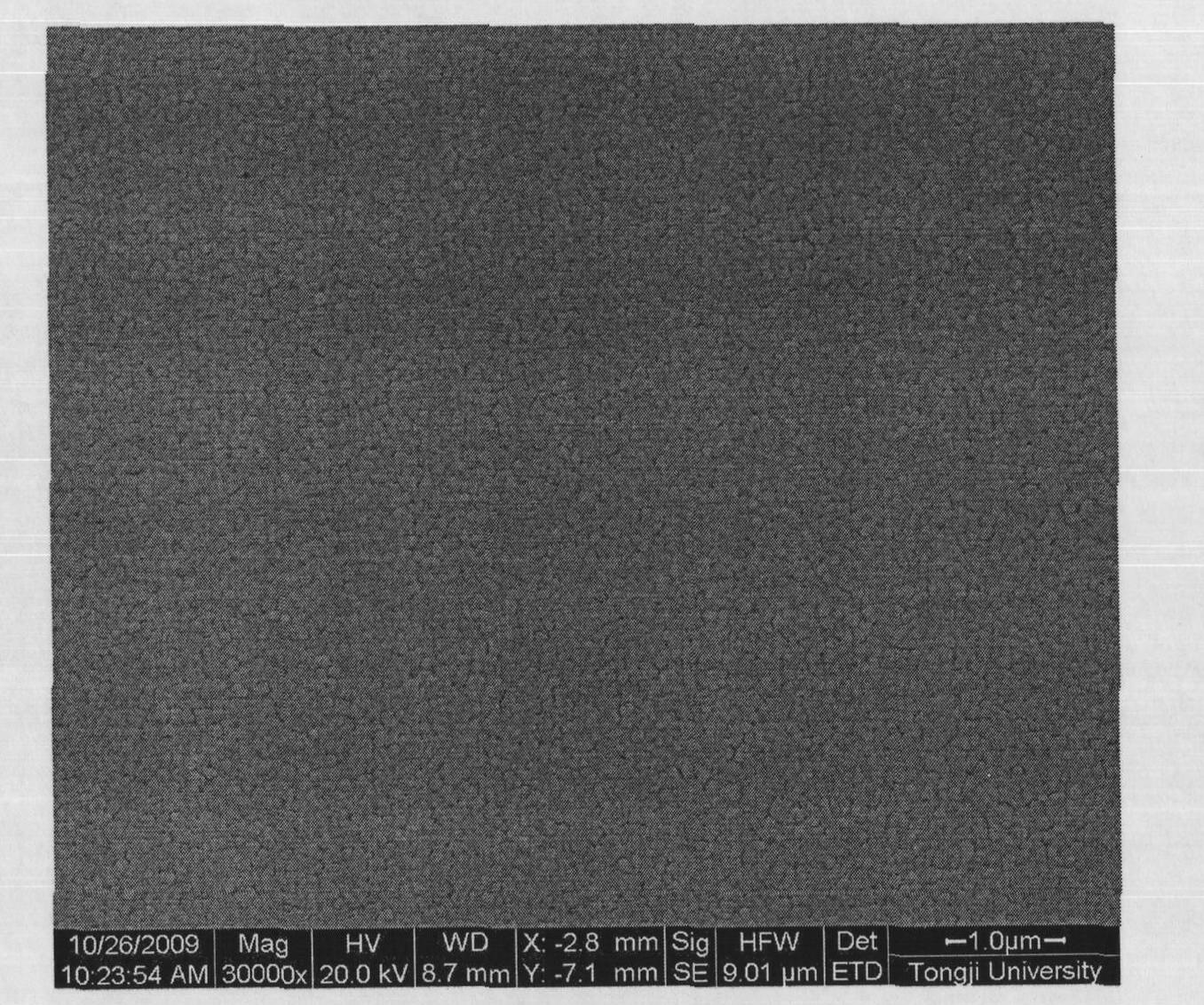

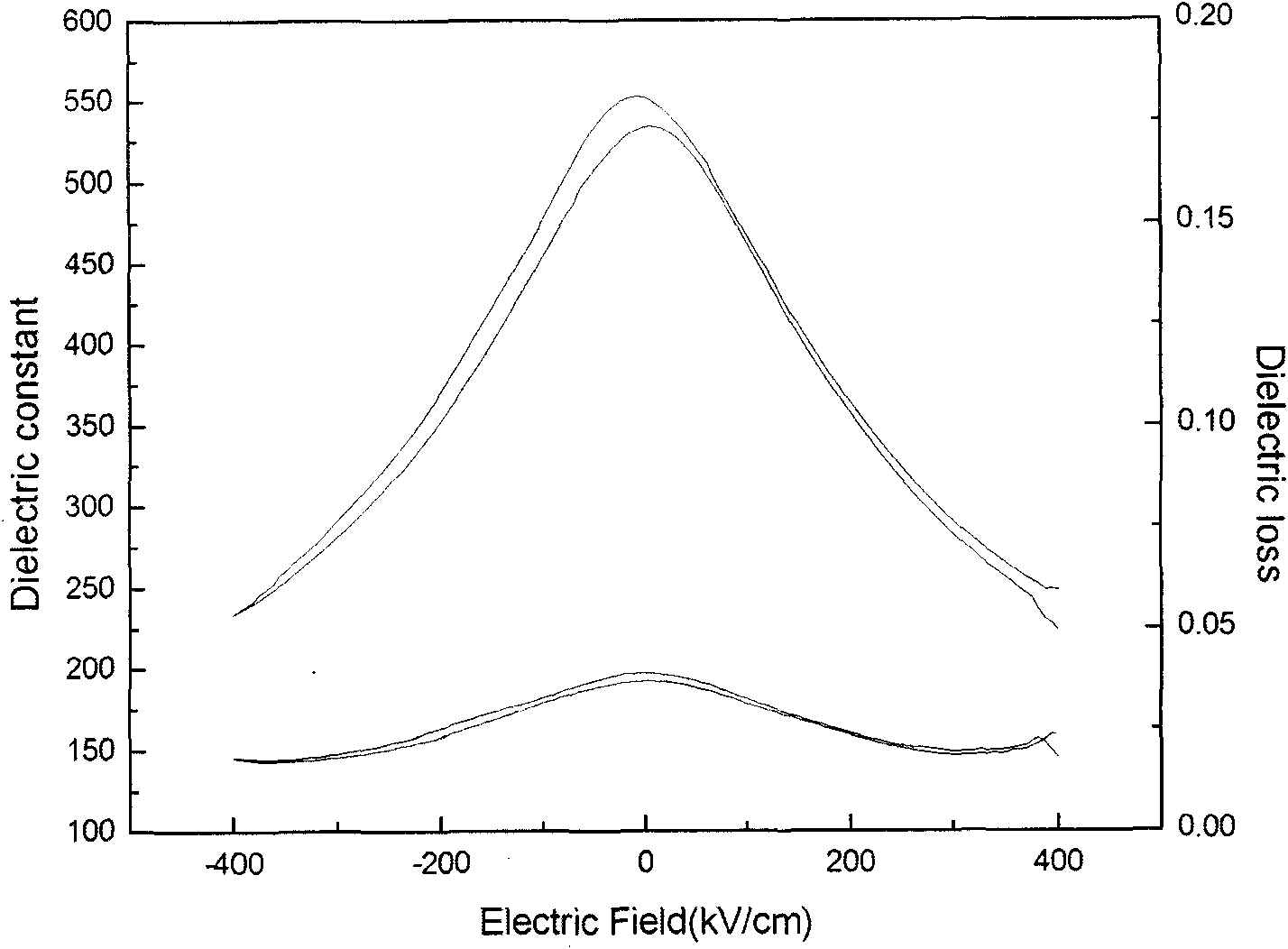

[0047] Embodiment 1: in Pt / Ti / SiO 2 / Si substrate prepared 0.94Na 0.5 Bi 0.5 TiO 3 -0.06BaTiO 3 Ferroelectric thin film

[0048] 1. The chemical raw materials used are bismuth nitrate (pentahydrate), sodium acetate (trihydrate), barium acetate and tetrabutyl titanate, and the solvent is glacial acetic acid and water (the volume ratio of glacial acetic acid and water is about 6:1 ). First bismuth nitrate (pentahydrate), sodium acetate (trihydrate) is 1.02:1 according to the molar ratio of bismuth nitrate and sodium acetate, and in the glacial acetic acid mixed solution of described bismuth nitrate and sodium acetate, bismuth nitrate and sodium acetate The sum of the molar concentrations is 0.6M; heated to boiling in glacial acetic acid solution, evaporated for 10 minutes, stirred at 60°C for about 120 minutes, cooled and stirred for 10 minutes, cooled to room temperature, and recorded as precursor solution 1. Mix ethylene glycol ether and acetylacetone (the volume ratio o...

Embodiment 2

[0055] Embodiment 2: in Pt / Ti / SiO 2 / Si substrate prepared 0.94Na 0.5 Bi 0.5 TiO 3 -0.06BaTiO 3 Ferroelectric thin film

[0056] 1. The chemical raw materials used are bismuth nitrate (pentahydrate), sodium acetate (trihydrate), barium acetate and tetrabutyl titanate, and the solvent is glacial acetic acid and water (the volume ratio of glacial acetic acid and water is about 10:1 ). First bismuth nitrate (pentahydrate), sodium acetate (trihydrate) is 1.10:1 according to the molar ratio of bismuth nitrate and sodium acetate, and in the glacial acetic acid mixed solution of described bismuth nitrate and sodium acetate, bismuth nitrate and sodium acetate The sum of the molar volume concentrations is 0.4M; heated to boiling in glacial acetic acid solution, evaporated for 5 minutes, stirred at 80°C for 120 minutes, cooled and stirred for 20 minutes, cooled to room temperature, and recorded as precursor solution 1. Mix ethylene glycol ether and acetylacetone (the volume ratio ...

Embodiment 3

[0061] Embodiment 3: in Pt / Ti / SiO 2 / Si substrate prepared 0.94Na 0.5 Bi 0.5 TiO 3 -0.06BaTiO 3 Ferroelectric thin film

[0062]1. The chemical raw materials used are bismuth nitrate (pentahydrate), sodium acetate (trihydrate), barium acetate and tetrabutyl titanate, and the solvent is glacial acetic acid and water (the volume ratio of glacial acetic acid and water is about 8:1 ). First bismuth nitrate (pentahydrate), sodium acetate (trihydrate) is 1.02:1 according to the molar ratio of bismuth nitrate and sodium acetate, and in the glacial acetic acid mixed solution of described bismuth nitrate and sodium acetate, bismuth nitrate and sodium acetate The sum of the molar volume concentrations is 0.2M; heated to boiling in glacial acetic acid solution, evaporated for 10 minutes, stirred at 60°C for about 120 minutes, cooled and stirred for 10 minutes, cooled to room temperature, and recorded as precursor solution 1. Mix ethylene glycol ether and acetylacetone (the volume r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercive field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com