Composite material with electromagnetic shielding effect and preparation method thereof

A technology of composite materials and composite material boards, applied in the jointing of wooden veneers, magnetic field/electric field shielding, paper coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

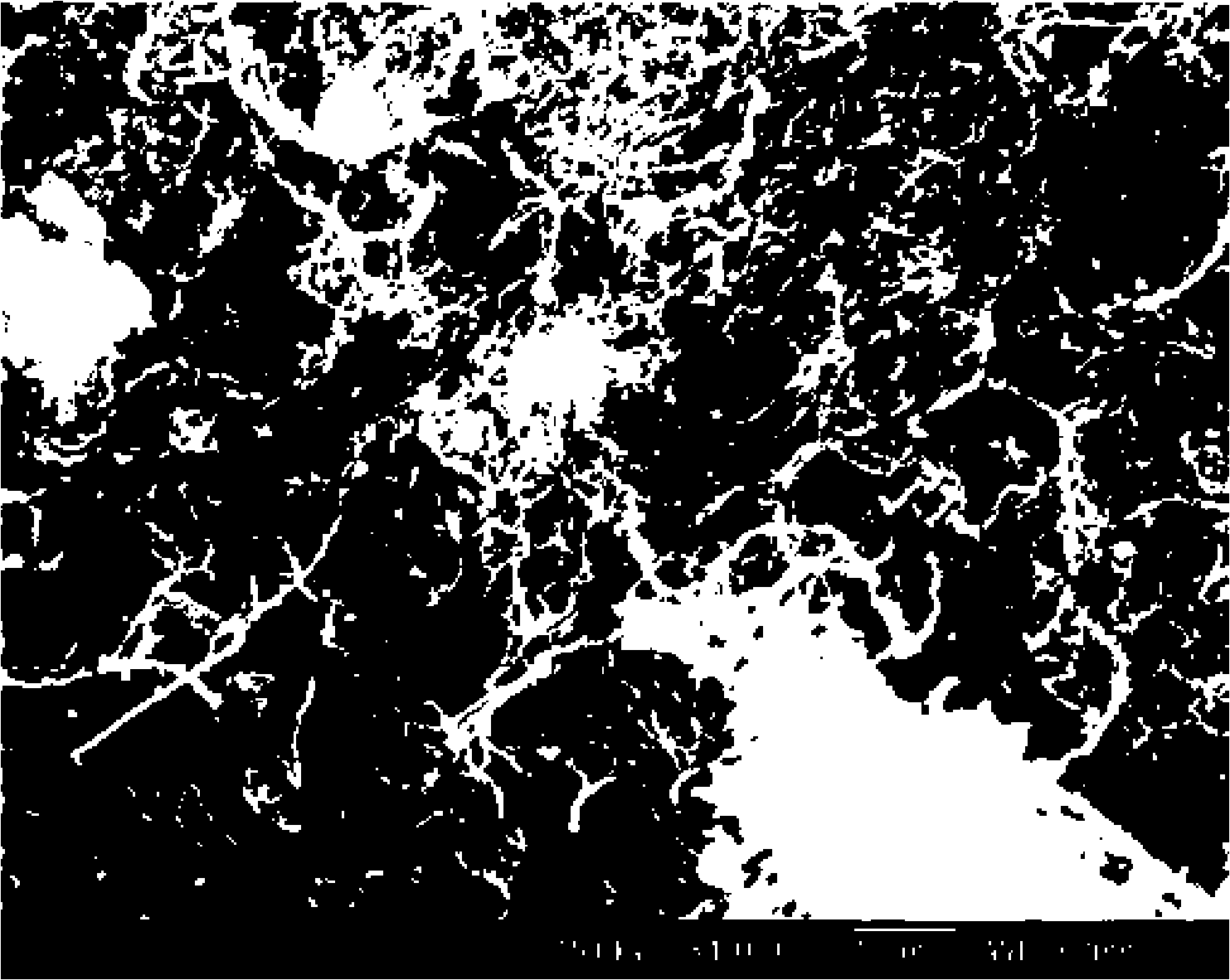

[0037] The multi-walled carbon nanotubes were azeotroped with 480g of sulfuric acid / nitric acid (160g of sulfuric acid and 320g of nitric acid) at 50°C for 24 hours, then washed with a large amount of pure water, filtered 6 times, and then dried. The multi-walled carbon nanotubes are azeotroped with a strong acid to generate -OH and -COOH functional groups on the surface, and the functional groups can make the multi-walled carbon nanotubes disperse in the polymer material.

[0038] 2.62 g of multi-walled carbon nanotubes modified according to the above method were dispersed in 50 g of toluene solvent, and 262 g of high-molecular polyacrylonitrile was added, and stirred at 25° C. to form a multi-walled carbon nanotube / polyacrylonitrile nanocomposite material. The above-mentioned multi-walled carbon nanotube / polyacrylonitrile nanocomposite material was coated on 20cm×20cm waste paper, and the coating thickness was 0.1mm.

[0039] Dry naturally or heat to evaporate the solvent an...

Embodiment 2

[0053] The multi-wall carbon nanotubes were first azeotroped with 480g of sulfuric acid / nitric acid (120g of sulfuric acid and 360g of nitric acid) at 40°C for 30 hours, then washed with a large amount of pure water, filtered 6 times, and then dried.

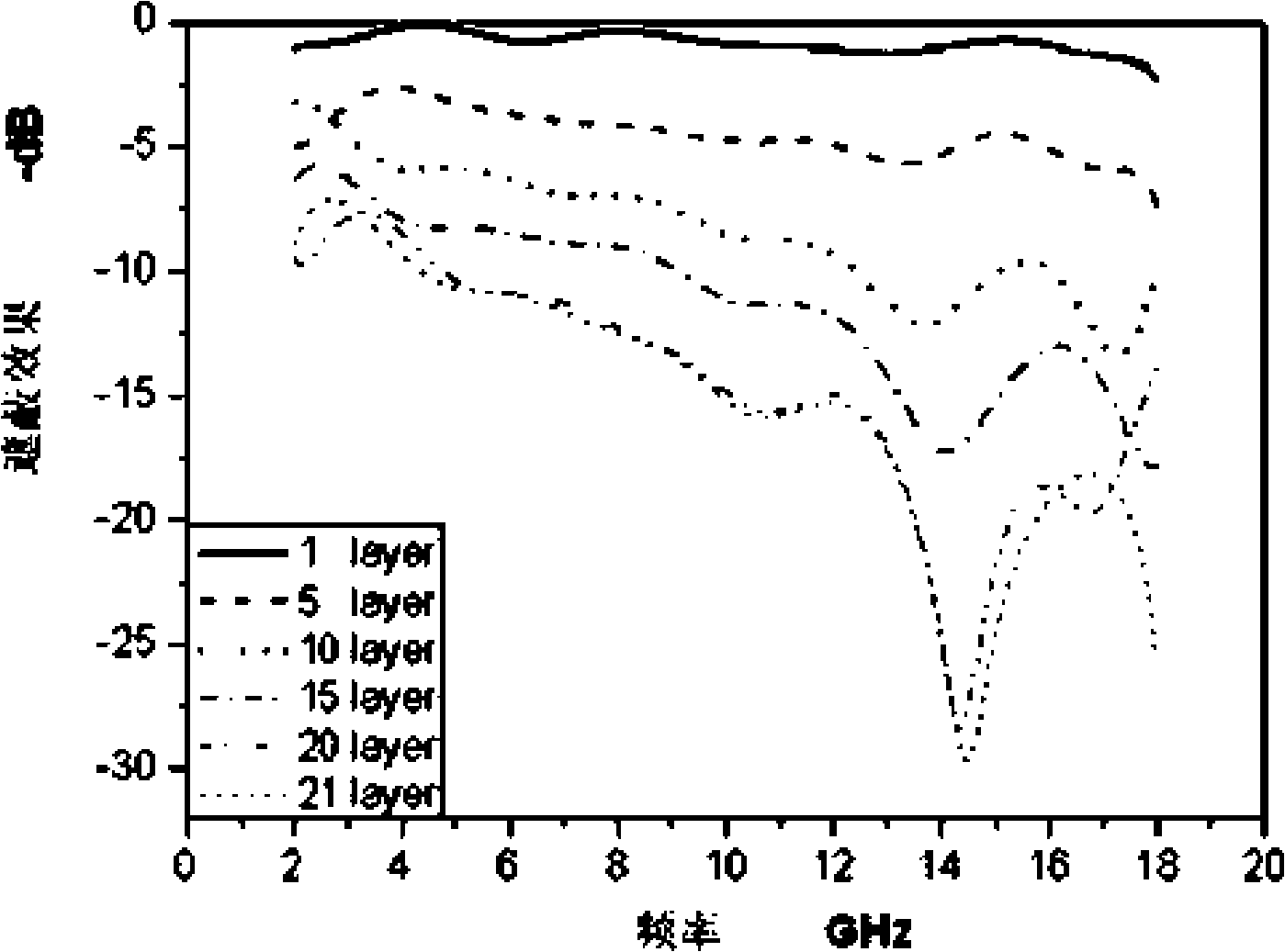

[0054] 4 g of multi-walled carbon nanotubes were dispersed in 30 g of dimethylacetamide solvent, added with 99.5 g of polymer polystyrene, and stirred at 25° C. to form a multi-walled carbon nanotube / polystyrene nanocomposite material. The above-mentioned multi-walled carbon nanotube / polystyrene nanocomposite material was coated on a 20 cm×20 cm PET film, and the coating thickness was 0.1 mm. And overlap them into boards (15 to 21 layers) as needed.

[0055] Among the above materials, multi-walled carbon nanotubes play the role of shielding electromagnetic waves, and dimethylacetamide is a good solvent for polyacrylonitrile, which can make the composite material into a gel and facilitate coating.

Embodiment 3

[0057] The multi-walled carbon nanotubes were first azeotroped with 480g of sulfuric acid / nitric acid (320g of sulfuric acid and 160g of nitric acid) at 70°C for 10 hours, then washed with a large amount of pure water, filtered 6 times, and then dried.

[0058] 0.5 g of multi-walled carbon nanotubes were dispersed in 15 g of tetrahydrofuran solvent, and 96 g of acrylonitrile-butadiene styrene copolymer was added.

[0059] Similar to Example 1, the difference is that the above-mentioned multi-walled carbon nanotube / acrylonitrile-butadiene styrene copolymer composite material is not coated on paper, but coated on a wood board, and its coating thickness 1.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com