Nylon 6 slice prepared by using waste fishing net and preparation method thereof

A technology for fishing nets and nylon, applied in the field of nylon 6 slices and its preparation, can solve the problems that the mechanical properties and appearance cannot meet the basic requirements of use, engineering plastics lose their use value, and the molecular weight of nylon 6 slices is low, so as to achieve great social effects and economic benefits. Benefits, low cost, less impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

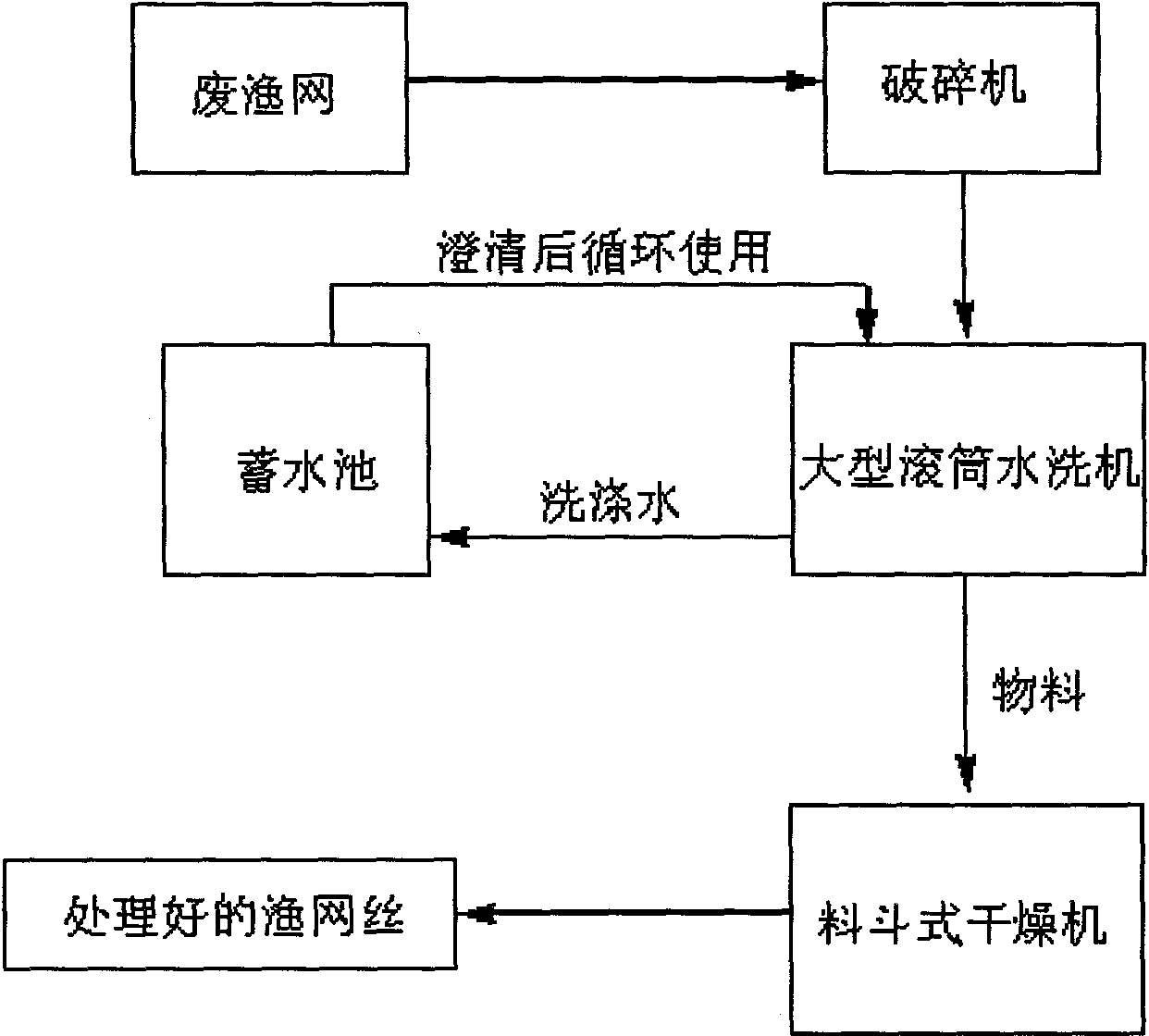

[0028] The recovered waste fishing nets are added to a high-speed crusher and broken into fragments with a diameter of less than 10 mm, then poured into a large drum washing machine to wash away the sediment and centrifugally dried, and then dried to a moisture content of 0.2% ( percent by weight).

[0029] With 98Kg above-mentioned dried waste fishing net fragments and 0.5Kg bisoxazoline, 0.5Kg hindered phenolic stabilizer: antioxidant 1098 (Yabao), 0.5Kg phosphite stabilizer: antioxidant 168 (Yabao ) and 0.5Kg magnesium stearate are mixed at a high speed in a high-speed mixer for 2min, and then added from the first feeder (main feed) into the twin-screw extruder that the die head is equipped with an 800-mesh metal filter screen, and the twin-screw extruder The temperature of the machine from the feed section to the head is: 245°C, 245°C, 245°C, 235°C, 230°C, 220°C, 220°C, 210°C, the temperature of the die head is 235°C, and it is water-cooled after extrusion , dicing, and t...

Embodiment 2

[0031] After the reclaimed waste fishing nets are processed to meet the requirements according to the treatment method in Example 1, the above-mentioned dried waste fishing net fragments of 98Kg are stabilized with 0.5Kg epoxy-based styrene-acrylate oligomer and 0.5Kg hindered phenol hindered phenols. Agent: Antioxidant 1098 (Abemarle), 0.5Kg phosphite stabilizer: Antioxidant 168 (Abemarle) and 0.5Kg polyester lubricant AC540 (Honeywell) mixed in a high-speed mixer for 2min Finally, feed it from the first feeder (main feed) into the twin-screw extruder with a 800-mesh metal filter installed in the die head. The temperature of the twin-screw extruder from the feeding section to the die head is: 245°C, 245°C, 235°C, 230°C, 220°C, 220°C, 210°C. The temperature of the die head is 235°C. After extrusion, it is water-cooled, pelletized, and then packaged to obtain PA6 slices.

Embodiment 3

[0033] After the reclaimed waste fishing nets are processed to meet the requirements according to the treatment method in Example 1, the above-mentioned dried waste fishing net fragments of 95Kg are mixed with 0.5Kg bisoxazoline, 0.5Kg epoxy-based styrene-acrylate oligomer, 1.5 Kg hindered phenolic stabilizer: antioxidant 1098 (Albemarle), 1.0Kg phosphite stabilizer: antioxidant 168 (Albemarle), 0.5KG cuprous iodide and 0.5Kg magnesium stearate, 0.5Kg Polyester lubricant AC540 (Honeywell) was mixed at a high speed in a high-speed mixer for 2 minutes, and then added from the first feeder (main feed) to a twin-screw extruder with a 800-mesh metal filter installed on the die head. The temperature of the screw extruder from the feed section to the head is: 245°C, 245°C, 245°C, 235°C, 230°C, 220°C, 220°C, 210°C, the temperature of the die head is 235°C, and the extrusion Afterwards, it is water-cooled, cut into pellets, and then packaged to obtain PA6 slices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com