Method for producing L-lactic acid by taking cassava powder as material

A technology of cassava flour and lactic acid, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve the effects of simple formula, easy-to-obtain ingredients, and simple and easy-to-operate process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

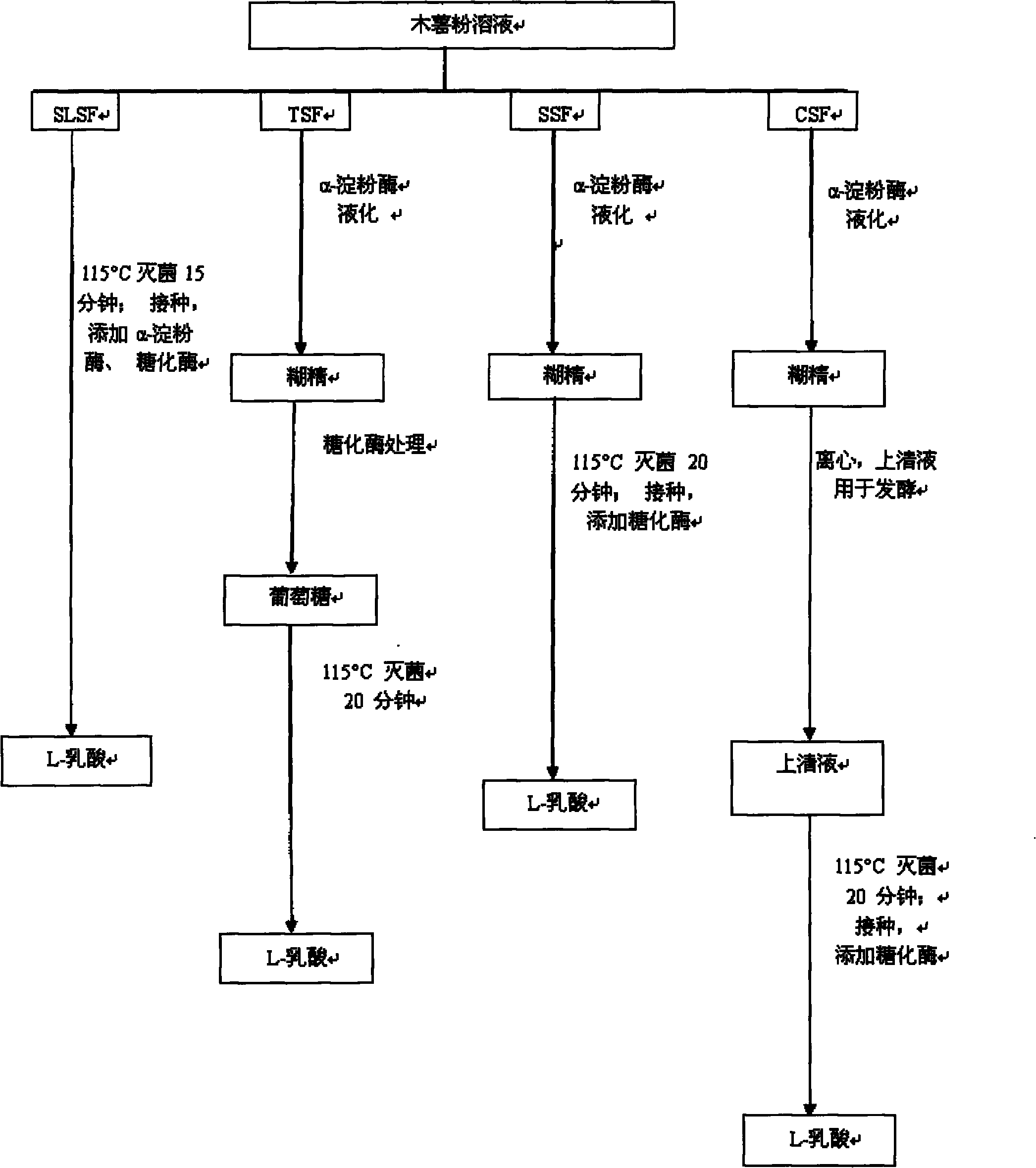

Method used

Image

Examples

Embodiment 1

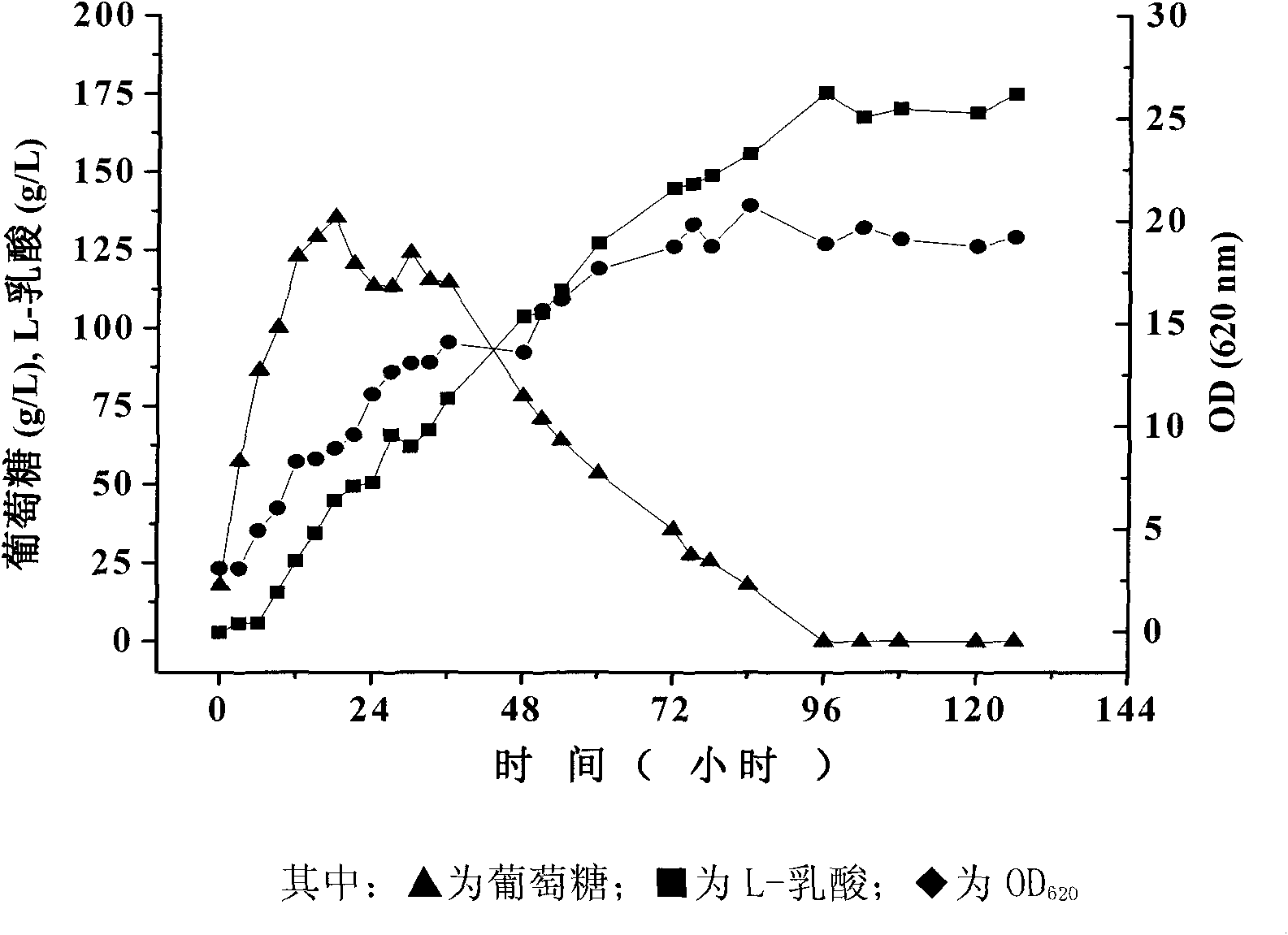

[0032] Embodiment 1, take cassava flour as raw material to ferment and produce L-lactic acid in the Erlenmeyer flask

[0033] The composition of the medium used in this embodiment is as follows:

[0034] Slant medium: glucose 20g / L, yeast extract 5g / L, peptone 10g / L, beef extract 10g / L, dipotassium hydrogen phosphate 2g / L, diammonium citrate 2g / L, sodium acetate 5g / L, spit Temperature 80 1ml / L, magnesium sulfate heptahydrate 0.58g / L, manganese sulfate tetrahydrate 0.25g / L, calcium carbonate 15g / L, agar powder 15g / L. The initial pH of the medium was 6.5. Sterilization was performed at 115°C for 20 minutes.

[0035] Seed medium: glucose 50g / L, yeast powder 15g / L, calcium carbonate 30g / L. The initial pH of the medium was 6.5. Sterilization was carried out at 115° C. for 20 minutes.

[0036] Fermentation medium: cassava flour 275g / L, yeast powder 10g / L, calcium carbonate 165g / L, α-amylase 20U / g cassava flour, glucoamylase 104U / g cassava flour. Sterilize at 115°C for 20 minutes...

Embodiment 2

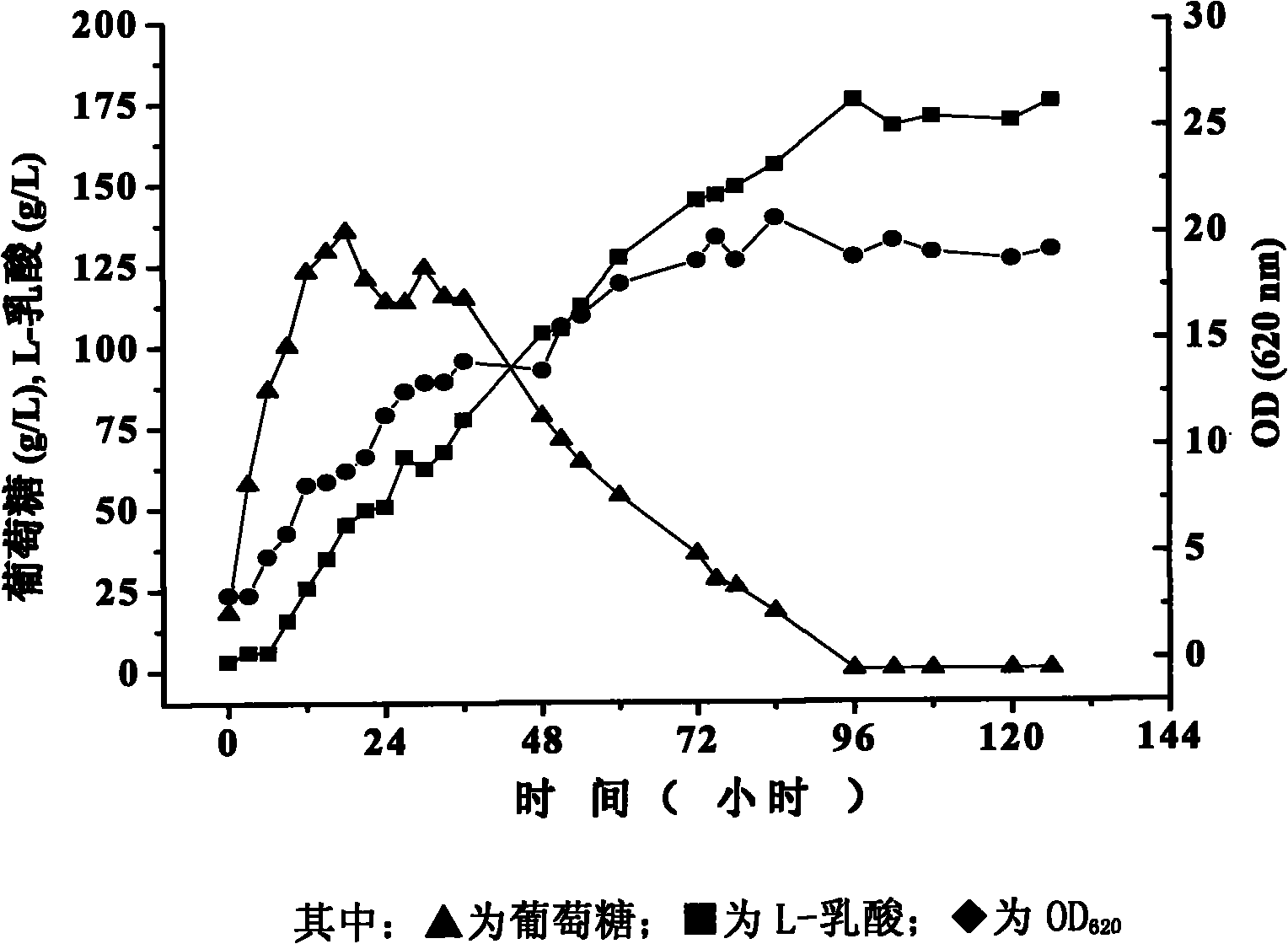

[0044] Embodiment 2, take cassava flour hydrolyzate as raw material two-step fermentation process to produce L-lactic acid

[0045] The composition of the medium used in this embodiment is as follows:

[0046] Slant culture medium and seed culture medium: with embodiment 1.

[0047] Fermentation medium: cassava flour hydrolyzate 275g / L, yeast powder 10g / L, calcium carbonate 165g / L. The initial pH of the medium was 6.5. Sterilization was carried out at 115° C. for 20 minutes.

[0048] The process adopted is a two-step fermentation method.

[0049] The cassava flour hydrolyzate can be prepared according to the following method, with a suitable concentration of cassava flour solution, adjust the pH to 6.0, add excess α-amylase (20U / g cassava flour), liquefy in a water bath at 95°C, and detect the color with iodine-potassium iodide Variety. After the liquefaction is complete, the sample is taken out and cooled. Adjust the pH to 4.2, add 104U / g cassava flour glucoamylase, and ...

Embodiment 3

[0055] Embodiment 3, using cassava flour hydrolyzate as raw material synchronous saccharification and fermentation process to produce L-lactic acid

[0056] The composition of the medium used in this embodiment is as follows:

[0057] The slant medium and seed medium are the same as in Example 1.

[0058] Fermentation medium: cassava flour liquefaction solution 275g / L, yeast powder 10g / L, calcium carbonate 165g / L. Sterilize at 115°C for 20 minutes.

[0059] The process adopted is synchronous saccharification and fermentation.

[0060] The method for producing L-lactic acid by fermentation method of the present invention comprises the following steps:

[0061] (1) inclined plane culture: with embodiment 1;

[0062] (2) seed culture: with embodiment 1;

[0063] (3) Fermentation culture: prepare cassava flour solution of appropriate concentration, adjust pH to 6.0, add excess α-amylase (20U / g cassava flour), liquefy in 95°C water bath, and detect color change with iodine-pot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com