Neutral ink base material with wide application and flash neutral ink prepared by same

A neutral ink and base material technology, applied in the field of writing materials, can solve the problems of single applicability, single compatibility and harm of pigments (dyes), achieve good thixotropy and other properties, high storage stability, and reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 rose red flash neutral ink

[0067] Get the following raw materials to prepare neutral ink base material:

[0068] 60kg deionized water

[0069] Ethylene glycol 15 kg

[0070] Sodium dodecyl sulfonate 10 kg

[0071] Zonyl 8868 (DuPont) 0.3 kg

[0072] Dihydroxyacylethylene titanate 3 kg

[0073] hydroxymethyl cellulose 1 kg

[0074] Propylene glycol 1 kg

[0075] Benzotriazole 0.01 kg

[0076] Water-based silicone oil 0.5 kg.

[0077] Inject deionized water, ethylene glycol, sodium dodecylsulfonate, Zonyl 8868, and dihydroxyacylethylene titanate into the reactor at room temperature, stir and mix well, and after 2 hours, under stirring conditions Add dropwise dimethylaminoethanol as a pH regulator, continue stirring for 1.0 hour, then add propylene glycol, benzotriazole, water-based silicone oil and hydroxymethylcellulose, and stir for another 20 minutes to obtain a neutral ink base.

[0078] Take the following raw materials to prepare pink glitter ...

Embodiment 2

[0086] Embodiment 2 blue flash neutral ink

[0087] Get the following raw materials to prepare neutral ink base material:

[0088] 60kg deionized water

[0089] Glycerol 45 kg

[0090] Sodium dodecyl sulfonate 1 kg

[0091] Fluorad FC-4430 10kg

[0092] Dihydroxyacylethylene titanate 0.5 kg

[0093] Hydroxyethyl Cellulose 5kg

[0094] Propylene glycol 0.01 kg

[0095] Benzotriazole 0.3 kg

[0096] Water-based silicone oil 0.05 kg.

[0097] Inject deionized water, propylene glycol, sodium dodecylsulfonate, Fluorad FC-4430, and dihydroxyacyl ethylene titanate into the reactor at room temperature, stir and mix well, and after 3 hours, under stirring conditions Add dimethylaminoethanol dropwise, continue to stir for 0.5 hours, then add propylene glycol, benzotriazole, water-based silicone oil and hydroxymethylcellulose, and stir for another 30 minutes to obtain a neutral ink base.

[0098] Take the following raw materials to prepare pink glitter neutral ink:

[0099] The...

Embodiment 3

[0106] Embodiment 3 common black neutral ink

[0107] The neutral ink base material obtained in Example 1 is used, combined with common black color paste, and fully stirred evenly to obtain common black neutral ink.

[0108] Can find out from above each embodiment: neutral ink base material of the present invention has very wide adaptability, not only can be used for preparing the glitter neutral ink of various colors, and can make common black neutral ink. The neutral ink base material also has the characteristics of easy storage, thus bringing great convenience to large-scale personalized production. Normally, a relatively large amount of neutral ink base material can be produced. When it is necessary to produce a certain color of glitter neutral ink, the compound of glitter neutral ink can be carried out immediately. It is faster and more efficient than directly mixing flash neutral ink.

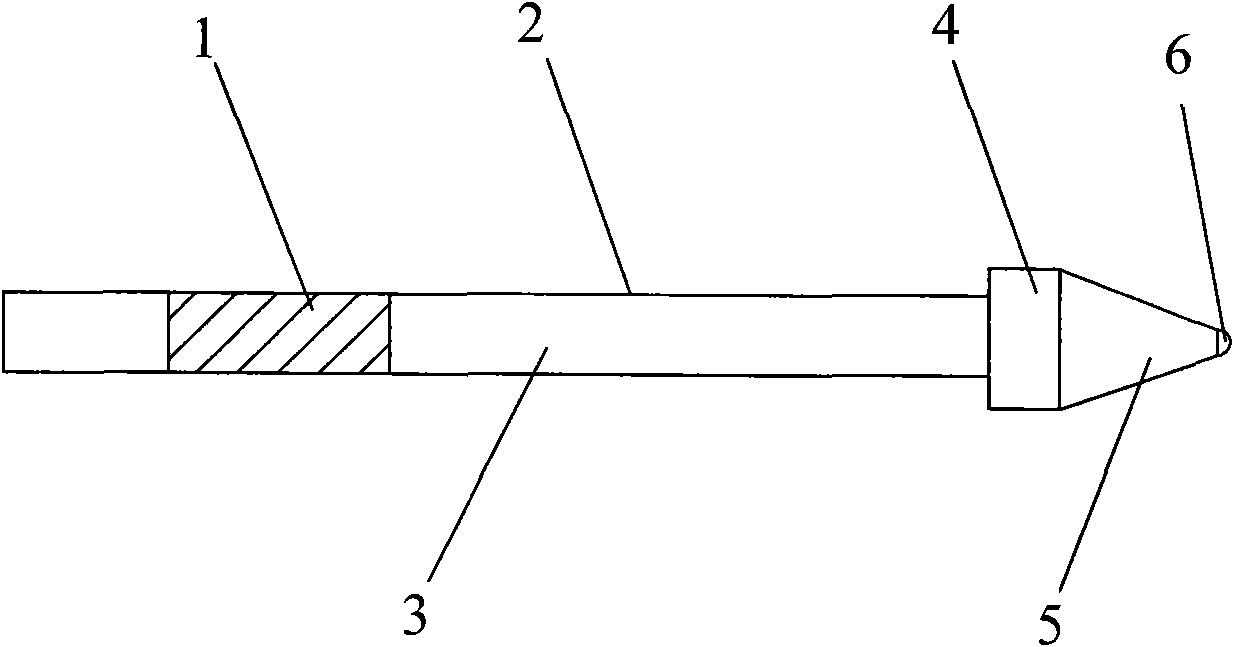

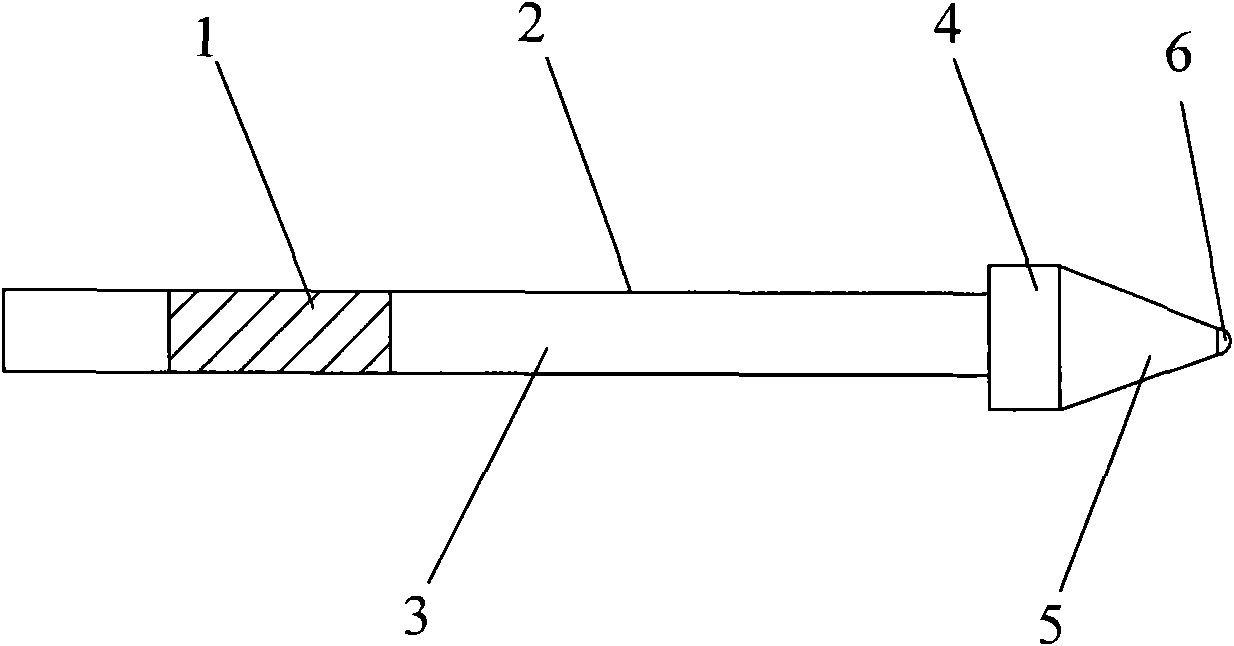

[0109] The ink obtained in each embodiment is tested with the writing pen shown in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com