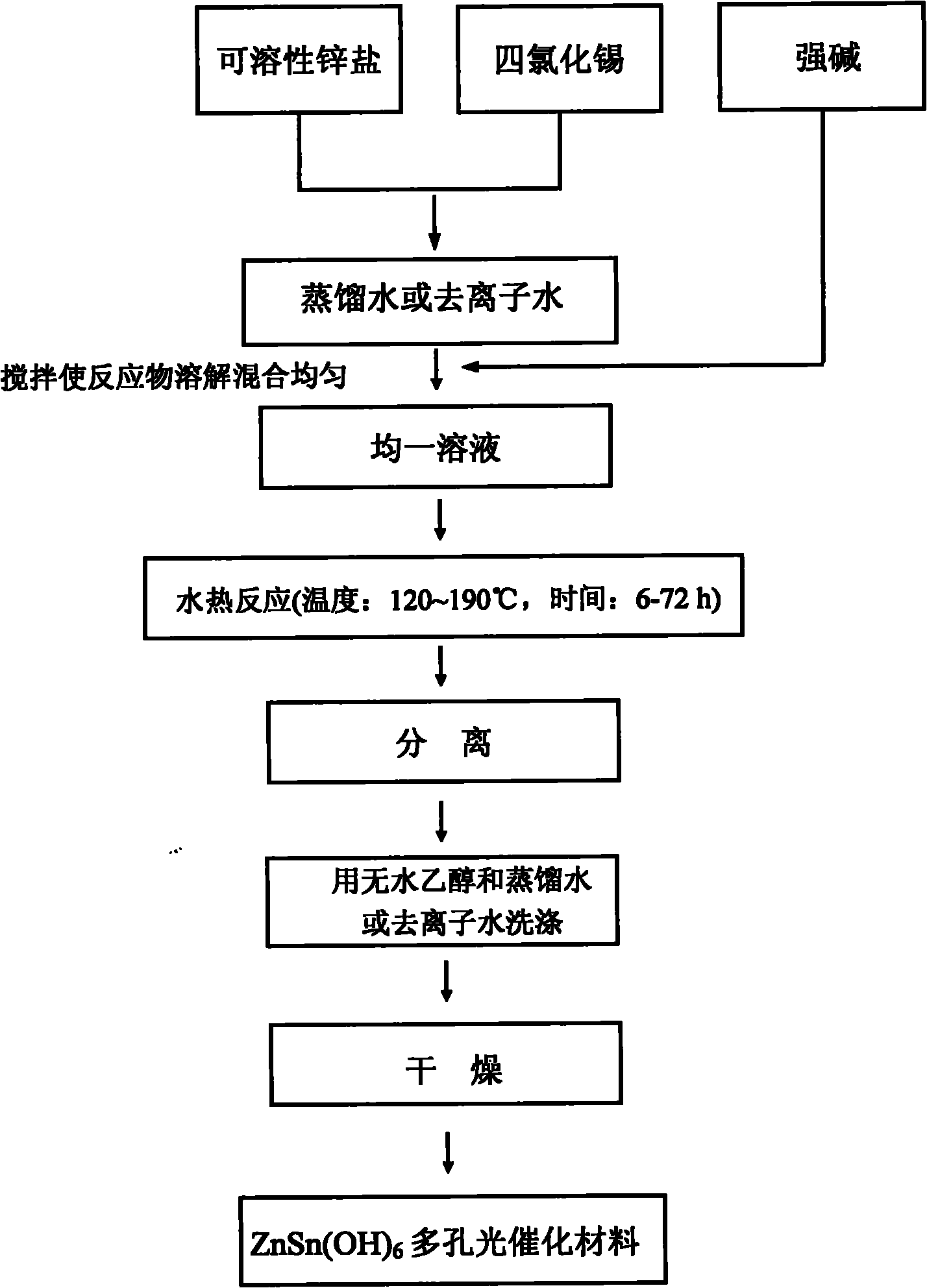

Preparation method of ZnSn(OH)6 porous photocatalytic material

A technology of photocatalytic materials and raw materials, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of lack of catalytic performance and application research reports, etc. It has the advantages of convenient operation, cheap and easy-to-obtain raw materials, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Step 1: Dissolve 0.3g of zinc acetate and 1.5g of tin tetrachloride in 63mL of deionized water, then add 1.5g of sodium hydroxide, and stir evenly to form a mixed solution.

[0019] Step 2: Transfer the mixed solution obtained in Step 1 to a 100mL stainless steel reaction kettle, and let it stand in a constant temperature oven at 170°C for 10h.

[0020] Step 3: After natural cooling, centrifuge and wash 3 times with deionized water and absolute ethanol respectively, and vacuum-dry the obtained white solid at 50°C to finally obtain ZnSn(OH) 6 Porous photocatalytic materials.

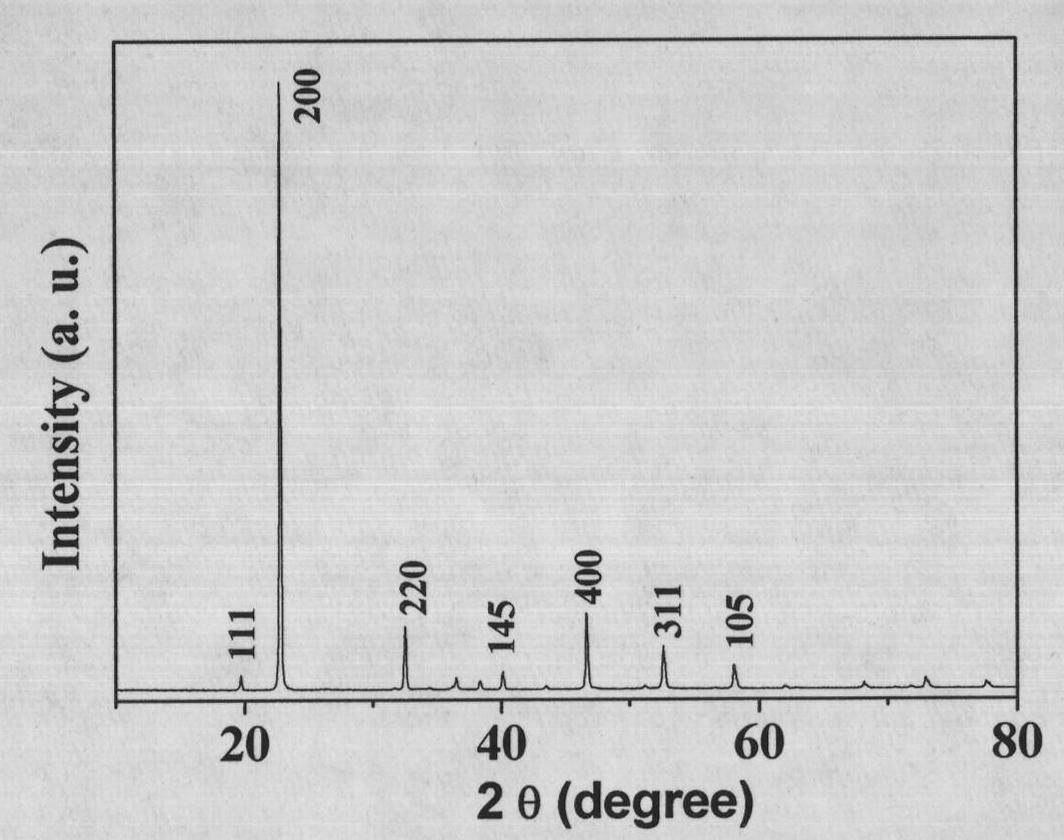

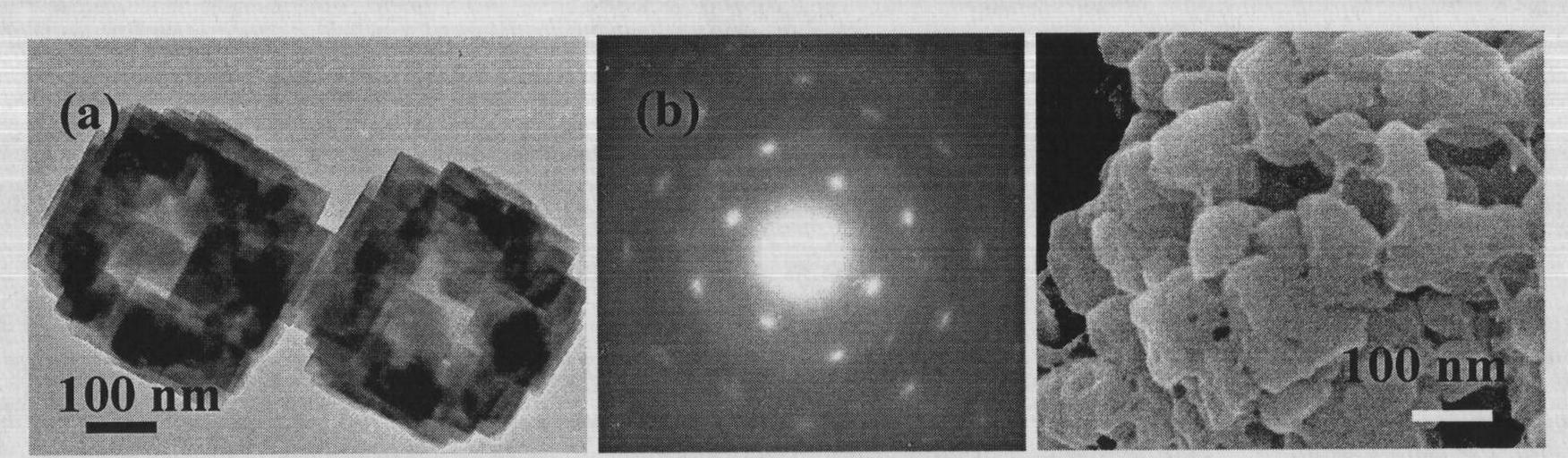

[0021] figure 2 The ZnSn(OH) prepared for this embodiment 6 The X-ray diffraction spectrum of the porous photocatalytic material, no diffraction peaks of other impurities are found in the spectrum, indicating that the obtained is ZnSn(OH) 6 . From image 3 (a) ZnSn(OH) can be seen 6 It is formed by the accumulation of some irregular particles with a particle size of less than 100nm. The colo...

Embodiment 2

[0024] Step 1: Dissolve 0.07g of zinc acetate and 0.33g of tin tetrachloride in 63mL of deionized water, then add 0.5g of sodium hydroxide and 0.28g of potassium hydroxide, and stir evenly to form a mixed solution.

[0025] Step 2: Transfer the mixed solution obtained in Step 1 to a 100mL stainless steel reaction kettle, and let it stand in a constant temperature oven at 150°C for 24h.

[0026] Step 3: After natural cooling, centrifuge and wash 3 times with deionized water and absolute ethanol respectively, and vacuum-dry the obtained white solid at 50°C to finally obtain ZnSn(OH) 6 Porous photocatalytic materials.

Embodiment 3

[0028] Step 1: Dissolve 1.5g of zinc nitrate and 5.34g of tin tetrachloride in 63mL of deionized water, then add 5.7g of potassium hydroxide, and stir evenly to form a mixed solution.

[0029] Step 2: Transfer the mixed solution obtained in Step 1 to a 100mL stainless steel reaction kettle, and let it stand in a constant temperature oven at 180°C for 12h.

[0030] Step 3: After natural cooling, centrifuge and wash 3 times with deionized water and absolute ethanol respectively, and vacuum-dry the obtained white solid at 50°C to finally obtain ZnSn(OH) 6 Porous photocatalytic materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com