Method for quickly precipitating and separating oversulfated chondroitin sulfate in sodium heparin

A technology of chondroitin polysulfate and precipitation separation, applied in the biological field, can solve the problems such as no reports of separation technology, insignificant separation effect, poor separation effect, etc., and achieve the effect of remarkable separation effect, improved color and lustre, and remarkable effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

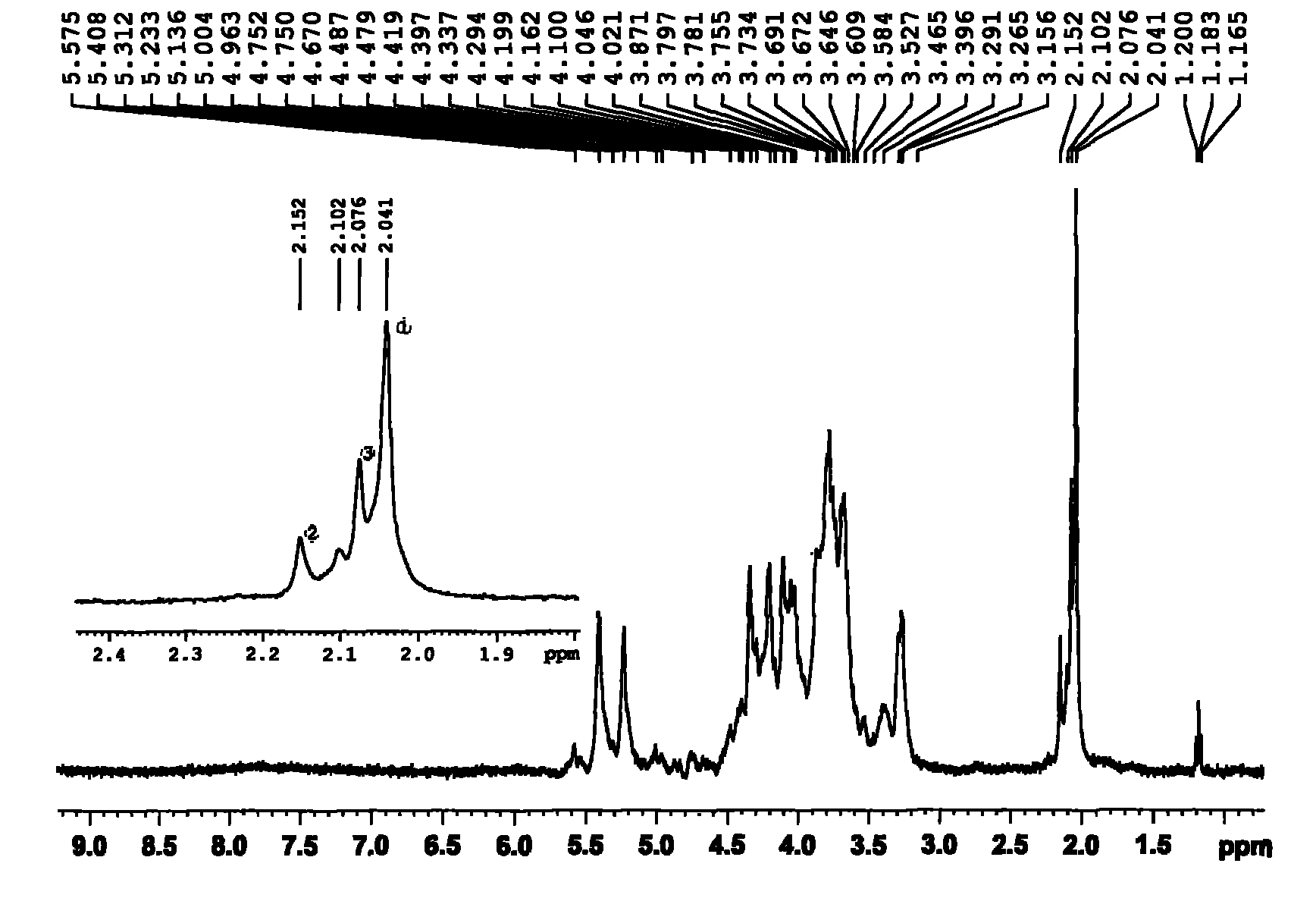

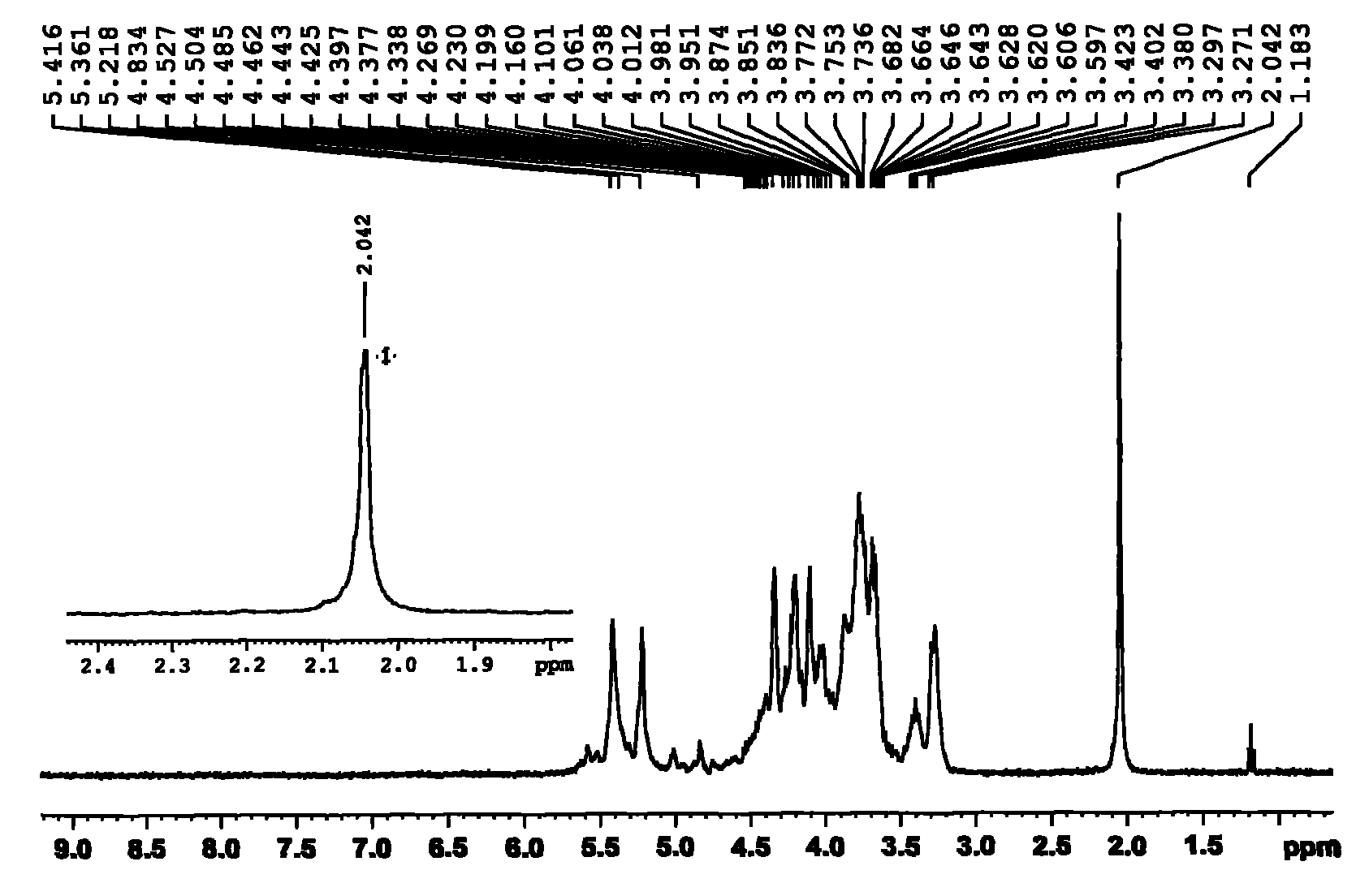

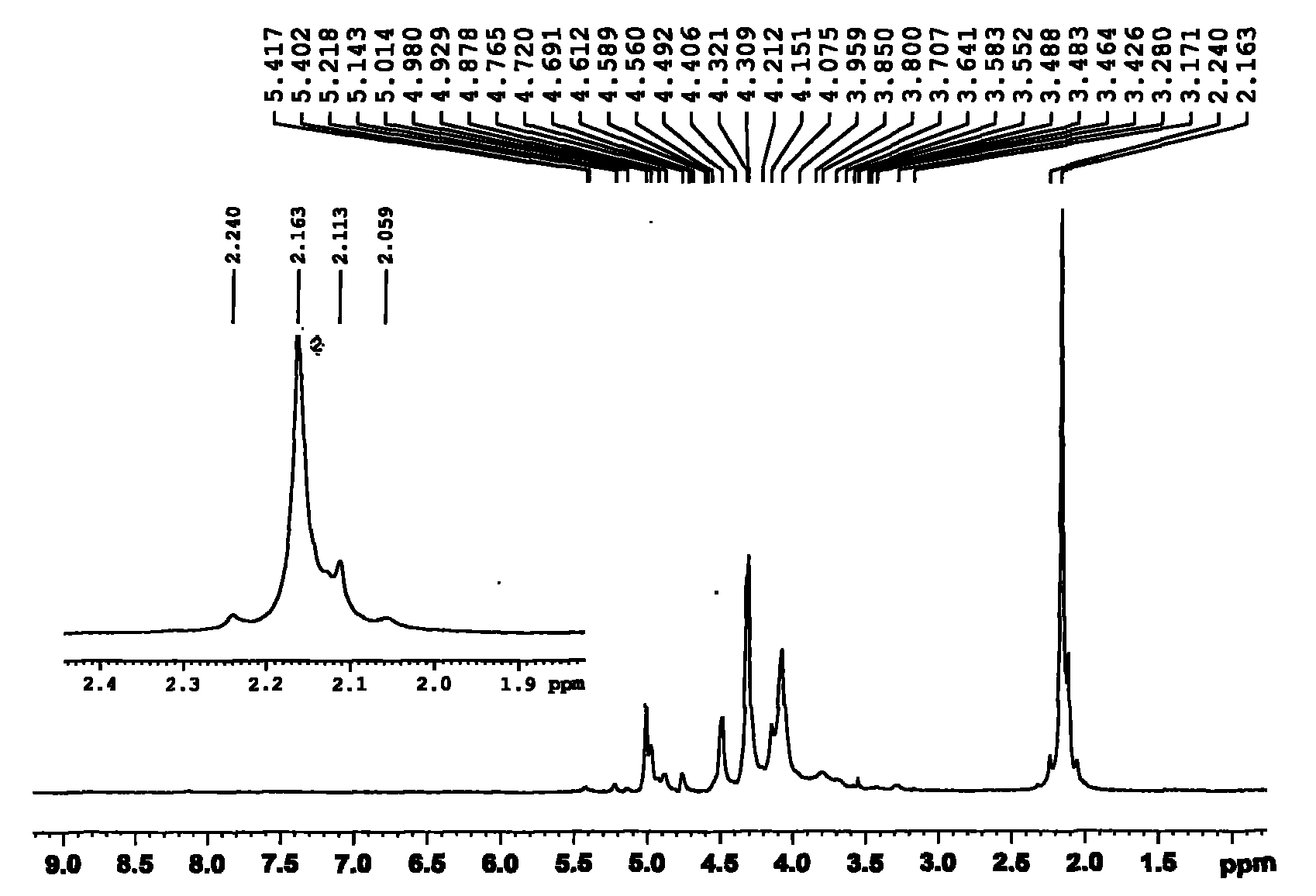

Image

Examples

Embodiment Construction

[0027] (1) Dissolving: open the water valve, add 1500L of drinking water in the reactor, while stirring, 15 billion total titers of crude product heparin sodium (crude product heparin sodium titer is 100IU / mg, the weight ratio of crude product heparin sodium and water is 1:10) into the reaction kettle, turn on the steam, raise the temperature to 55°C±5°C, and stir for 5 hours to completely dissolve the heparin sodium;

[0028] (2) Filtration: filter with a 100-mesh filter screen, wash the filter residue with a small amount of water, collect the filtrate and lotion (the two are combined);

[0029] (3) Resin adsorption: pump the filtrate into the treated 3000L anion exchange resin adsorption column, control the flow rate at 50L / h, and circulate the effluent into the barrel for 24 hours;

[0030] (4) Cleaning: stop the adsorption after the titer of the effluent is detected to be constant. Absorption residual liquid is emptied. Clean the resin with water, and then prepare 10000L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com