Surface processing method and device of moderate and high strength carbon fibre

A high-strength carbon fiber and surface treatment technology, applied in fiber treatment, carbon fiber, physical treatment, etc., can solve problems such as difficult handling, loss of carbon fiber tensile strength, carbon fiber damage, etc., to achieve surface modification, reduce defects, and reduce guide rollers Quantity, the effect of avoiding later damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

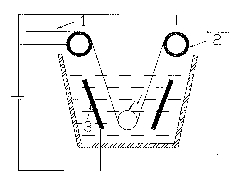

Image

Examples

Embodiment 1

[0024] The electrolyte solution is configured with the formula (composite solution 1) of sodium succinate 56g / l, succinic acid 9g / l, and ammonium oxalate 16g / l, and the carbon fiber is subjected to continuous electrochemical oxidation treatment. The electrolytic cell is a traditional electrolytic cell. The treatment temperature is 30°C, the treatment time is 60s, and the applied current density is 3mA / cm 2 , followed by cleaning at room temperature, drying at 100°C, gluing, and collecting the product.

Embodiment 2

[0026] Electrolyte solution (composite solution 1) is configured with the formula of sodium succinate 56g / l, succinic acid 9g / l, and ammonium oxalate 16g / l, and carbon fiber is subjected to continuous electrochemical oxidation treatment. The electrolytic cell type is A, and the treatment temperature is 30℃, treatment time is 60s, applied current density is 3mA / cm 2 , followed by cleaning at room temperature, drying at 100°C, gluing, and collecting the product.

Embodiment 3

[0028] The electrolytic solution (composite solution 1) is prepared with the formula of sodium succinate 56g / l, succinic acid 9g / l, and ammonium oxalate 16g / l, and the carbon fiber is subjected to continuous electrochemical oxidation treatment. The electrolytic cell form is traditional, and the treatment temperature 35℃, treatment time is 100s, applied current density is 1.5mA / cm 2 , followed by cleaning at room temperature, drying at 100°C, gluing, and collecting the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com