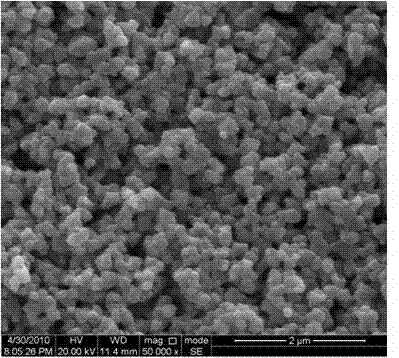

Preparation method of lithium ion battery nanocrystalline lithium titanate anode material

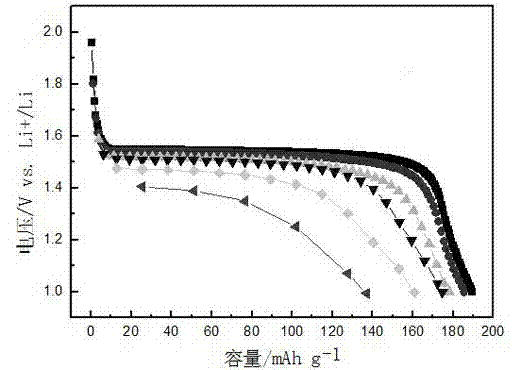

A lithium-ion battery, crystalline lithium titanate technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of uneven particle size distribution, poor electrochemical activity, long sintering time, etc. The effect of short time and short diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Embodiment 1: The preparation method of the nanocrystalline lithium titanate anode material of lithium ion battery in this embodiment is as follows: 1. Dissolve 2.4 to 2.8 g of lithium acetate in a mixed solution of 20 ml of ethanol and water, and stir for 10 min to obtain liquid A , the volume ratio of ethanol to water in the mixture of ethanol and water is 3:1; 2. Add 2ml of concentrated nitric acid or 2ml of concentrated hydrochloric acid to 8.8-10ml of tetrabutyl titanate and 20ml of absolute ethanol, and then stir under strong magnetic Add 3g ~ 4.25g block copolymer under the condition of strong magnetic stirring to form a uniform phase, and then add 4ml concentrated nitric acid or 4ml concentrated hydrochloric acid in four times to obtain B liquid; 3. Under the condition of strong magnetic stirring, mix A liquid and B liquid mixed with liquid, let stand for 10 minutes, continue to stir for 5-10 minutes, and then incubate for 48-72 hours at a temperature of 40°C and...

specific Embodiment approach 2

[0009] Embodiment 2: This embodiment differs from Embodiment 1 in that step 1 dissolves 2.5 g of lithium acetate or 2 g of lithium hydroxide in a mixed solution of 20 ml of ethanol and water. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 2, 9ml of tetrabutyl titanate or 10ml of titanium isopropoxide is added dropwise to 20ml of absolute ethanol. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com