Novel polyamide nanofiltration membrane and preparation method thereof

A technology of polyamide and nanofiltration membranes, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve good hydrophilicity and chlorine resistance, high removal rate, and novel preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Use 16% Udel P3500 polysulfone, 0.3% water and 0.1% nonylphenol polyoxyethyl ester phosphate to dissolve N, N-dimethylacetamide, apply it on the polyester non-woven fabric, and then dip it into After gelling in water and removing the solvent, a support membrane with a molecular weight cut-off of 20,000-30,000 is obtained, which is stored in a wet state for future use.

[0034] Immerse one side of the wet polysulfone support membrane in an aqueous solution with a weight ratio of 0.1% of piperidine and a weight ratio of 0.25% of sodium hydroxide for two minutes, roll the surface of the support membrane with a rubber roller and squeeze it dry, and mix with the weight of aromatic acid The isopar solvent oil solution with a ratio of 0.1% is contacted on one side to carry out the interfacial polymerization reaction for 20-40 seconds, the composite film is dried in the air for 2 minutes, and then treated at 40-70° C. for 3-10 minutes. Then carry out two steps of rinsing again:...

Embodiment 2-9

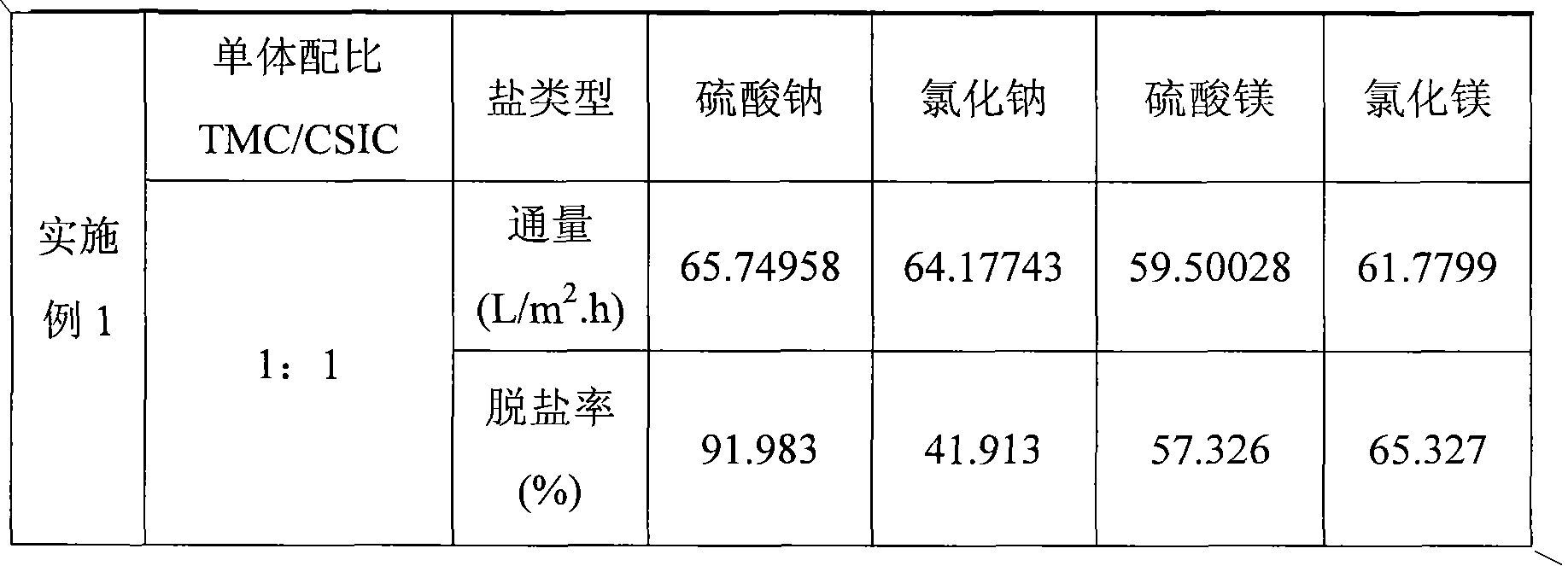

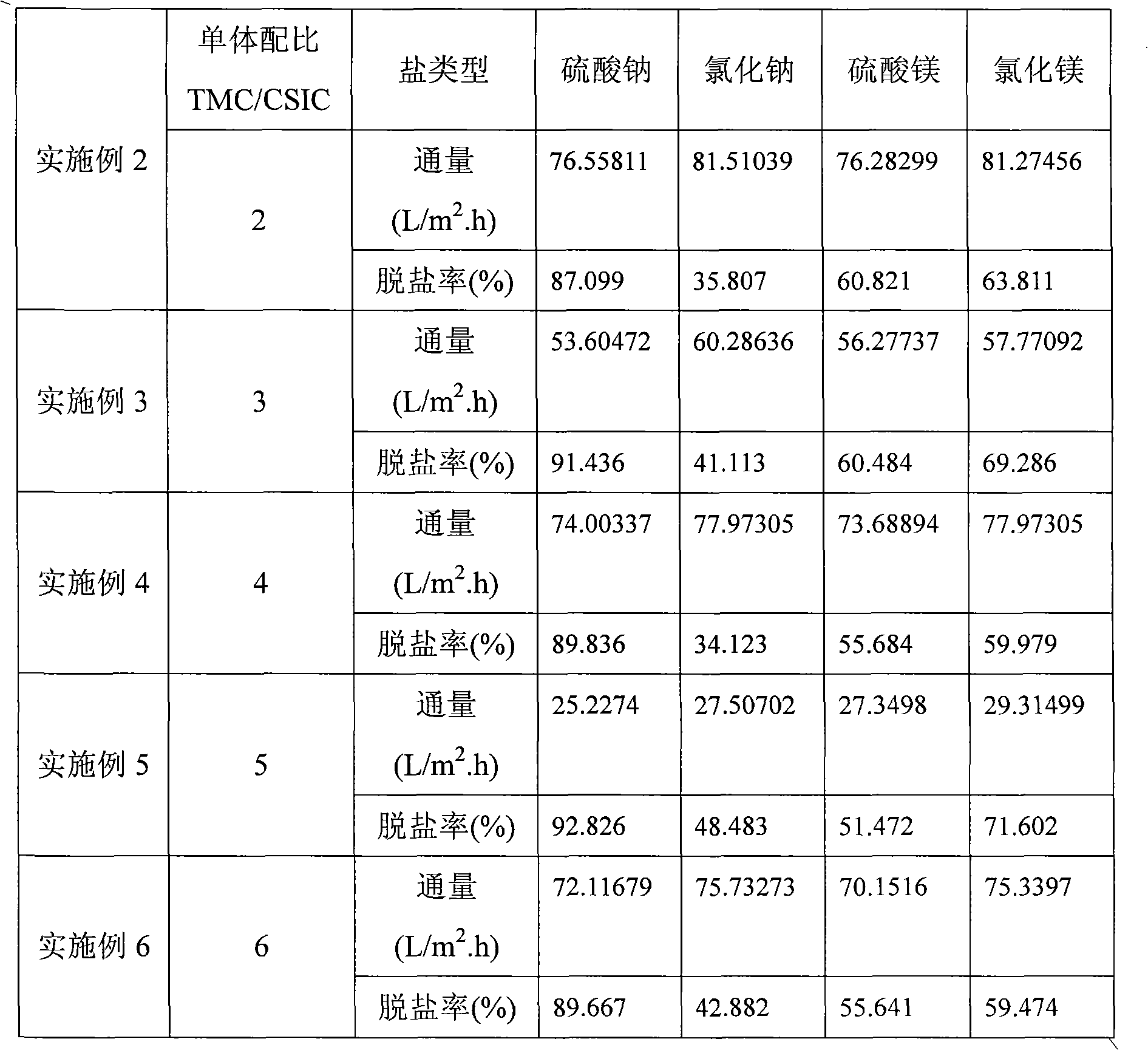

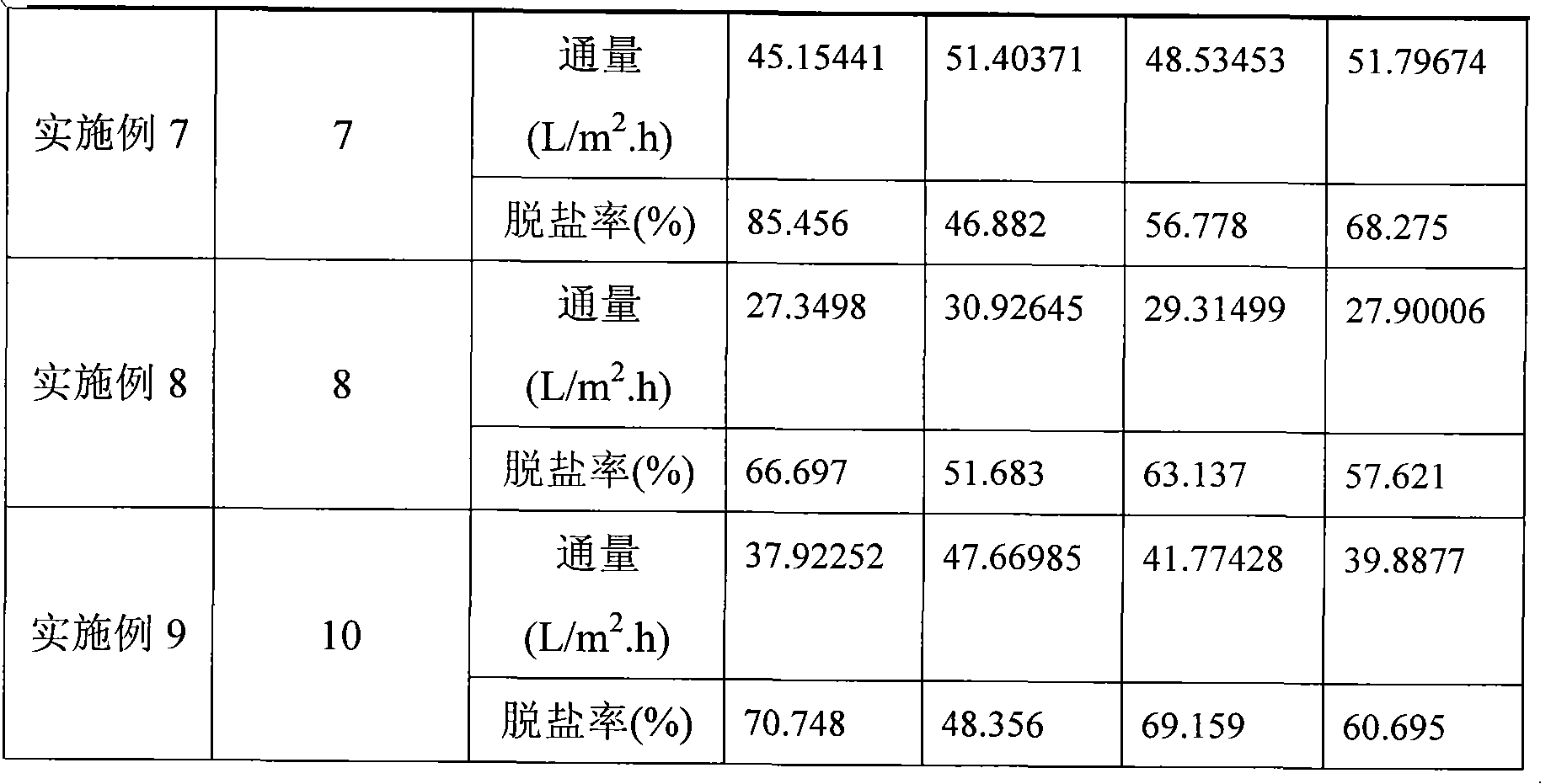

[0039] Other conditions are all the same as in Example 1, and the ratio of TMC and CSIC in the mixture solvent oil solution of 5-sulfonyl chloride isopeptidyl chloride and trimesoyl chloride is changed, and the results are shown in Table 2

[0040] Table 2

[0041]

[0042]

[0043] CSIC in the present invention refers to 5-chlorosulfonyl chloride isophthaloyl chloride, and isopar solvent oil is C11-C13 aliphatic hydrocarbon solvent oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com