Polymer emulsion for polymer-containing sewage treatment and preparation method thereof

A polymer emulsion and sewage treatment technology, applied in water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, mining wastewater treatment, etc. , to achieve the effect of clear water, compact floc, and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

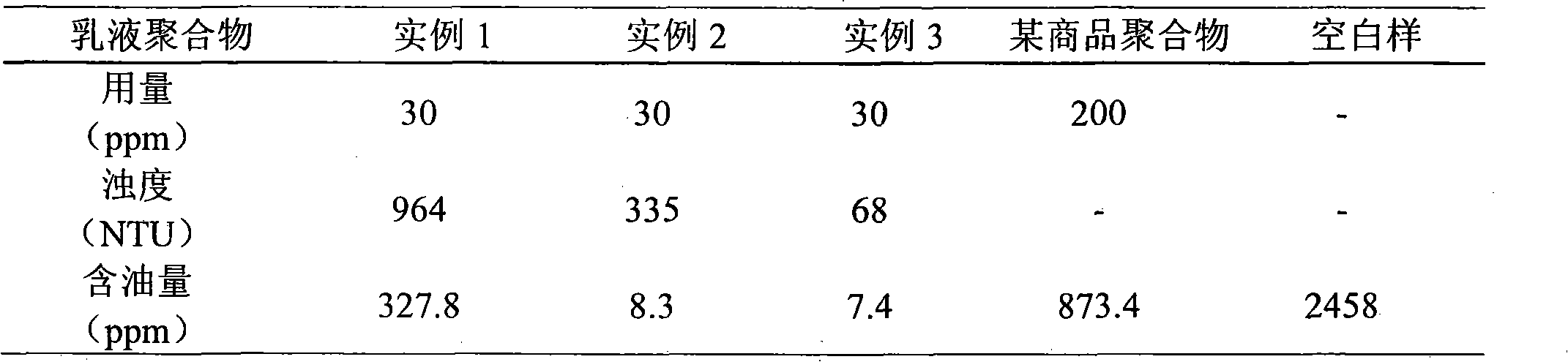

Embodiment 1

[0012] Weigh 16.2g AM, 43.8g DAC, 86.4g water, 6.1g MOA-3, 2.6g MOA-9 and 57.6g odorless kerosene into a 250mL three-necked flask in turn, and stir at room temperature at high speed (1200r / min) After emulsifying for one hour, a uniform and stable white emulsion was obtained. Then, in a water bath at 45°C, pass nitrogen to the prepared emulsion for 30 minutes to remove oxygen, add 0.06 g of initiator V-50 at a stirring speed of 260 r / min, and react at a constant temperature for about 5 hours to obtain a colorless and transparent polymer Physical emulsion (slightly yellowish when there are impurities). The solid content of the obtained emulsion was 45%, the cationic degree of the polymer was 50%, and the intrinsic viscosity of the polymer was 1324ml / g.

Embodiment 2

[0014] Weigh 12g AM, 48g DAC, 86.4g water, 6.1g MOA-3, 2.6g MOA-9 and 57.6g odorless kerosene into a 250mL three-necked flask in turn, and emulsify a hours, a uniform and stable white emulsion was obtained. Then, in a water bath at 45°C, pass nitrogen to the prepared emulsion for 30 minutes to remove oxygen, add 0.06 g of initiator V-50 at a stirring speed of 260 r / min, and react at a constant temperature for about 5 hours to obtain a colorless and transparent polymer animal emulsion. The solid content of the obtained emulsion was 45%, the cationic degree of the polymer was 60%, and the intrinsic viscosity of the polymer was 1073ml / g.

Embodiment 3

[0016] Weigh 8.4g AM, 51.6g DAC, 86.4g water, 6.1g MOA-3, 2.6g MOA-9 and 57.6g odorless kerosene into a 250mL three-necked flask in turn, and stir at room temperature at high speed (1200r / min) After emulsifying for one hour, a uniform and stable white emulsion was obtained. Then, in a water bath at 45°C, pass nitrogen to the prepared emulsion for 30 minutes to remove oxygen, add 0.06 g of initiator V-50 at a stirring speed of 260 r / min, and react at a constant temperature for about 5 hours to obtain a colorless and transparent polymer animal emulsion. The solid content of the obtained emulsion was 45%, the cationic degree of the polymer was 70%, and the intrinsic viscosity of the polymer was 1174ml / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com