A method and device for surface modification of polymer materials

A polymer material and surface modification technology, applied in the field of polymer material surface modification, can solve the problems of unsatisfactory grafting effect on the surface of polymer materials, uncontrollable reaction temperature, and incapable of continuous production, etc. The effect of shortening the reaction time and improving the grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

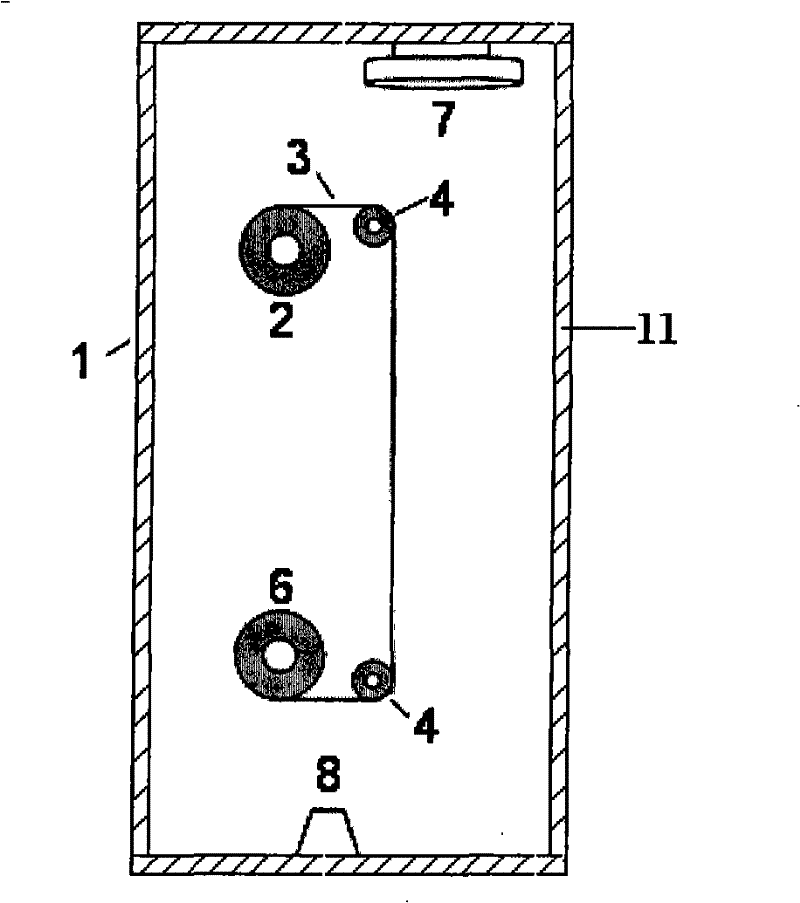

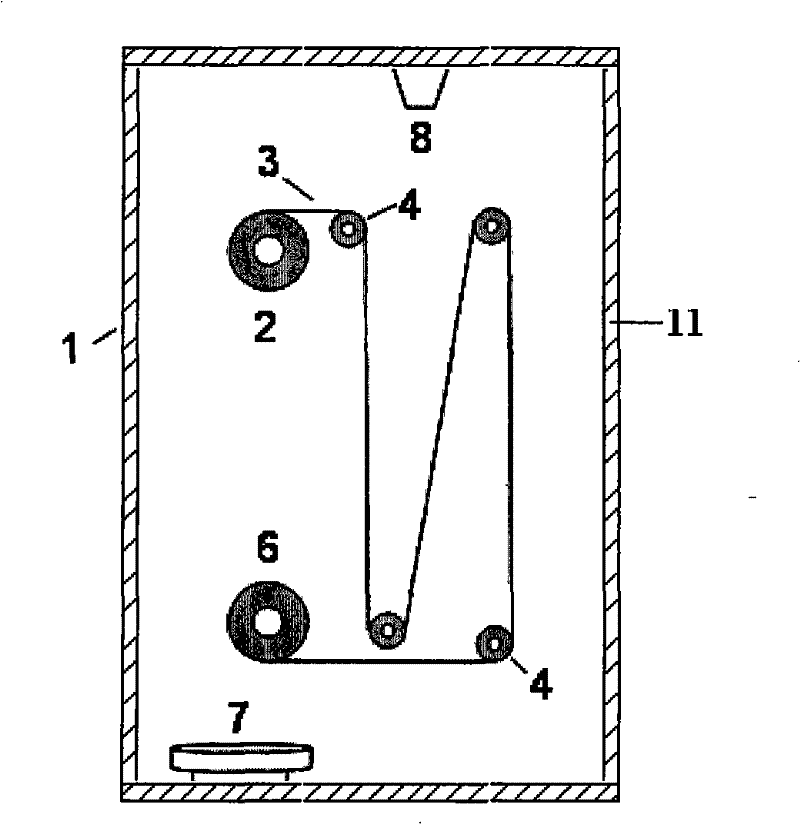

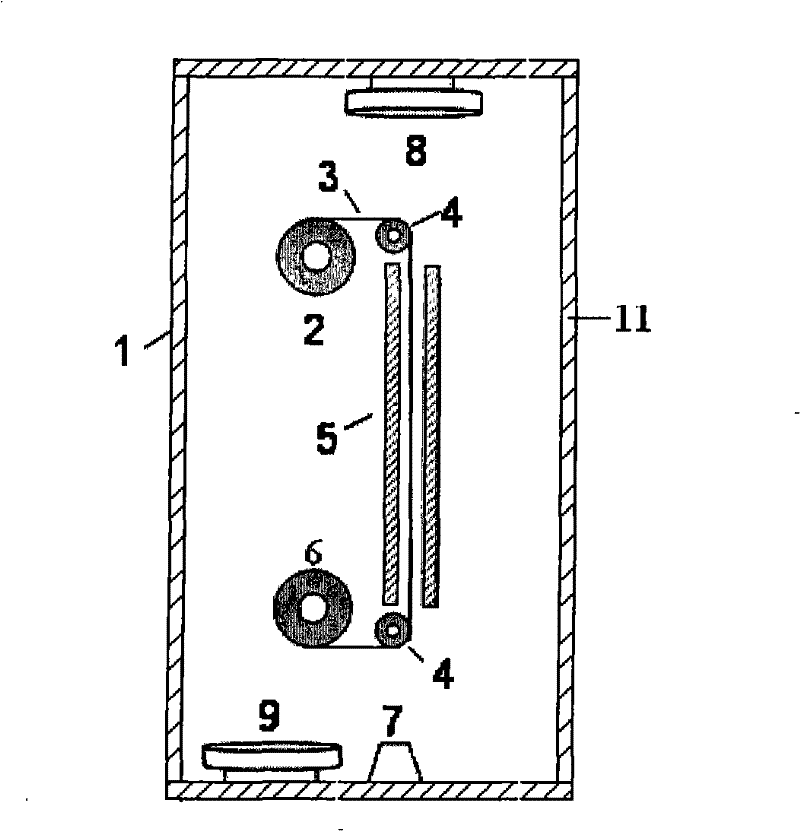

[0048] Plasma Initiated Vapor Phase Grafting of Acrylic Acid (AAc) on Polypropylene (PP) Films

[0049] Working conditions: argon, frequency 13.56MHz, power 100W.

[0050] Place the polypropylene film in the plasma processor, evacuate the system pressure to 50Pa, and the flow rate of the working gas argon is 800cm 3 / min, treated under the above conditions for 10min, the polypropylene film after plasma treatment was placed in the air at normal temperature and pressure for 50min to generate peroxide.

[0051] The polypropylene film placed in the air is placed in a reaction chamber with a pressure of 500Pa and a temperature of 60°C, and the liquid acrylic monomer (molecular weight 72.06g / mol; under normal temperature and pressure, density 1.05g / cm 3 ; under normal pressure, boiling point 141°C) preheated to 70°C in advance, the preheated liquid monomer enters the above reaction chamber and immediately vaporizes, the flow rate of the gaseous monomer is controlled at 2000cm 3 / m...

Embodiment 2

[0053] Plasma Initiated Vapor Phase Grafting of Acrylic Acid (AAc) on Polypropylene (PP) Films

[0054] Working conditions: argon, frequency 40KHz, power 600W.

[0055] Place the polypropylene film in the plasma processor, evacuate the system pressure to 50Pa, and the flow rate of the working gas argon is 100cm 3 / min, under the above conditions for 10min, the plasma treatment ends.

[0056] The polypropylene film after plasma treatment is placed in a reaction chamber with a pressure of 50 Pa and a temperature of 50°C. The liquid acrylic monomer is preheated to 70°C in advance. The flow rate of the body is controlled at 500cm 3 / min, the grafting reaction time is 15min, after the reaction is completed, the gaseous monomer supply is stopped first, the vacuum is continued for 1min, the atmosphere is connected, the reaction chamber returns to normal pressure, and the modified polypropylene film is taken out.

Embodiment 3-6

[0058] The technological process of embodiment 3-6 and part technological parameter are with embodiment 1, and different technological parameter is as described in the following table:

[0059] Process conditions

[0060] Description: PP means polypropylene; PBT means polybutylene terephthalate; PTFE means polytetrafluoroethylene; PE polyethylene; PPS polyphenylene sulfide; AAc means acrylic acid; HEMA means methacrylic acid-2-hydroxyethyl ester; GMA means glycidyl methacrylate; MAAc methacrylic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com