Method for producing sponge iron co-production sodium aluminate solution by using Bayer process red mud

A Bayer red mud and sodium aluminate technology, which is applied in the preparation of alkali metal aluminate/alumina/aluminum hydroxide, can solve the problems of increased red mud discharge, complicated process, and high cost, and achieves Environmental protection, easy technical parameters, and the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

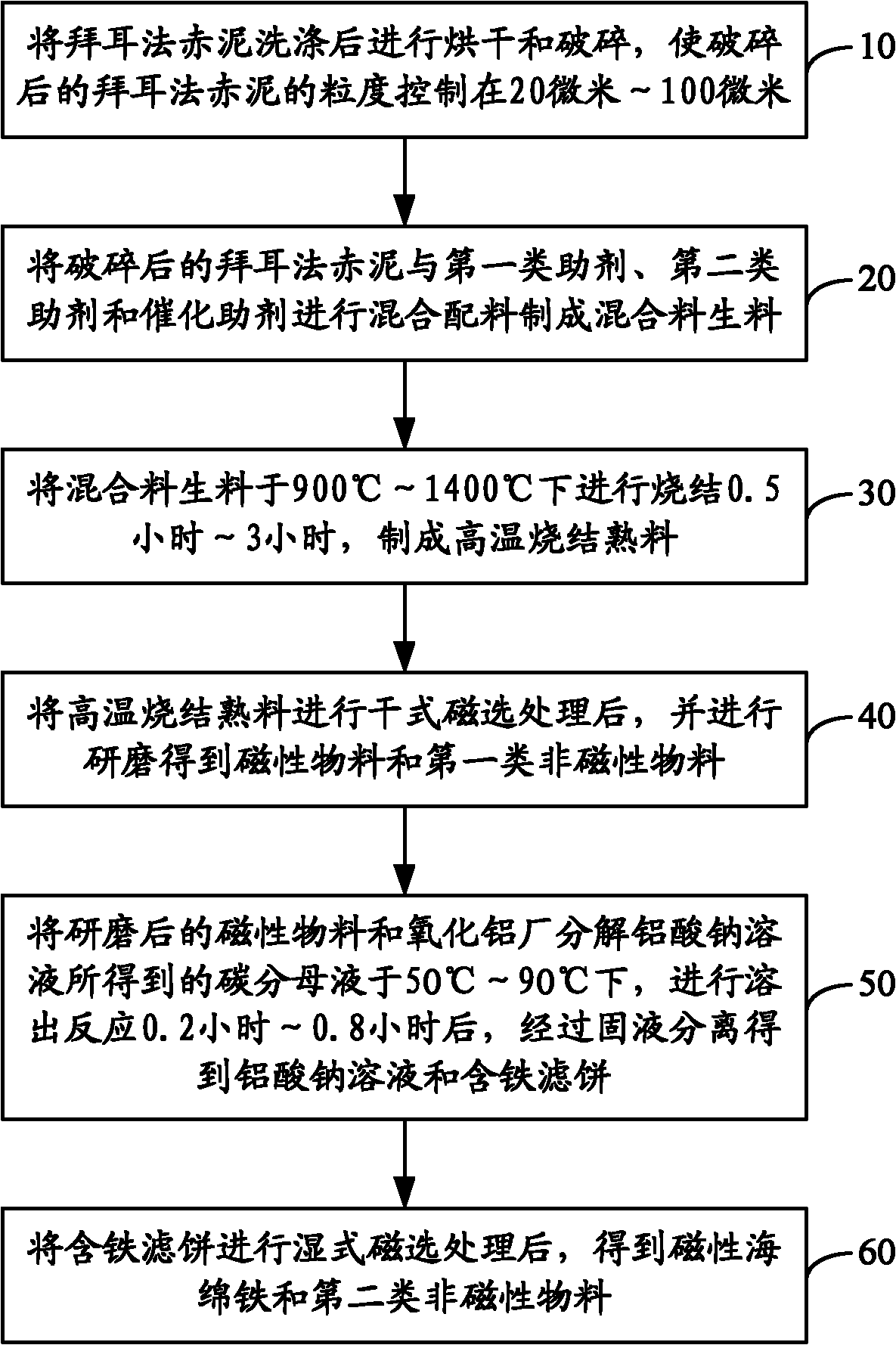

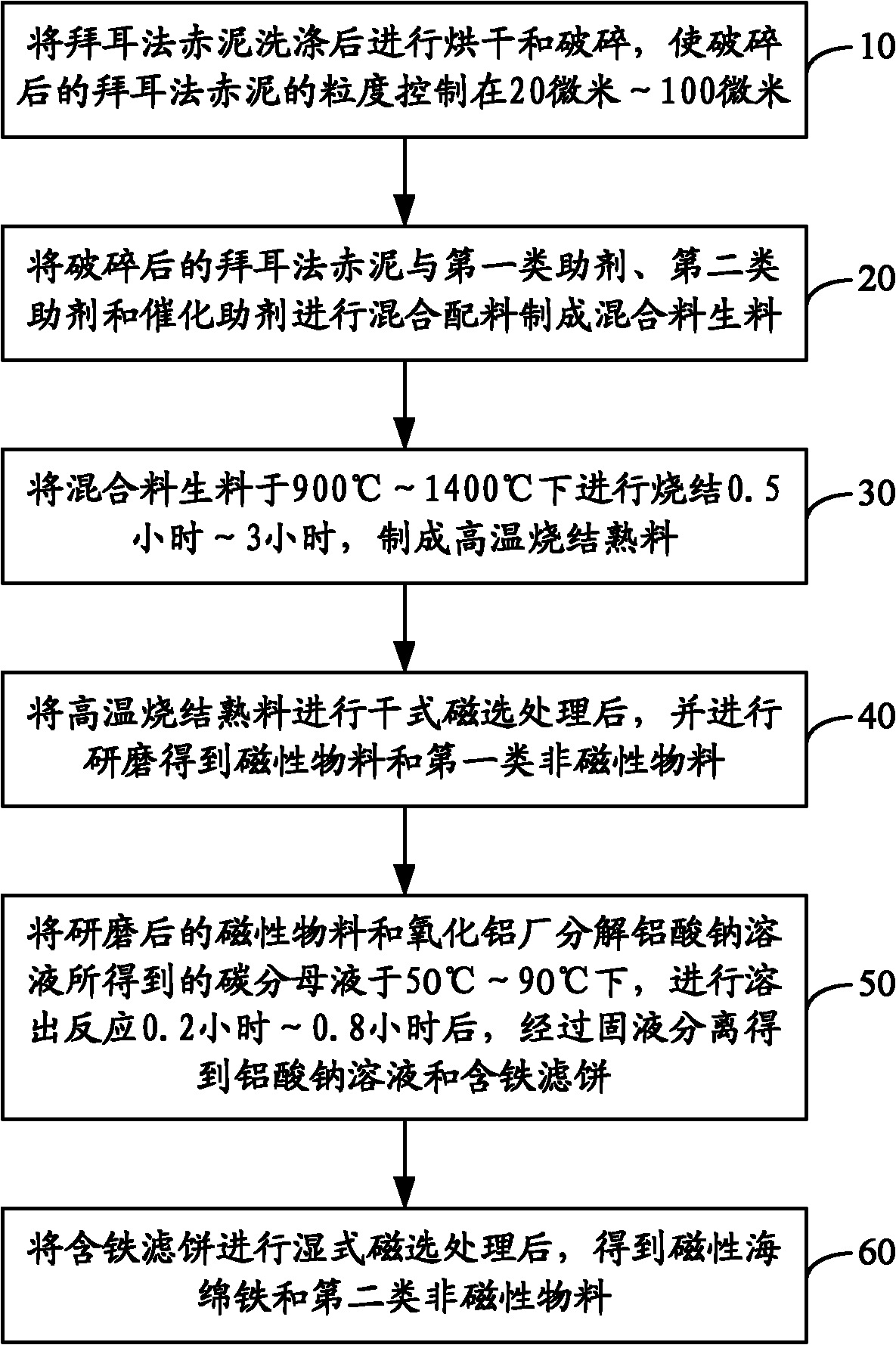

Method used

Image

Examples

Embodiment 1

[0058] In this example, Fe in the Bayer process red mud 2 o 3 The mass content is 28%, comprises the following steps:

[0059] (1) drying and crushing after washing the Bayer red mud, so that the particle size of the broken Bayer red mud is 30 microns;

[0060] (2) Mix the crushed Bayer process red mud with the first type of auxiliary agent, the second type of auxiliary agent and the catalytic auxiliary agent to make the mixture raw meal,

[0061] Among them, the first type of additive is a mixture of coke, anthracite, lignite and returned sintered material (the mass ratio of the four substances is 3:2:2:3), including 70% of the particles with a particle size of 20 microns by weight percentage. The first type of additives and 30% of the first type of additives with a particle size of 5 microns, the amount of the first type of additives is 1.8 times the theoretical carbon content required to reduce all the iron oxide in the Bayer process red mud ,

[0062] The second type o...

Embodiment 2

[0072] In this example, Fe in the Bayer process red mud 2 o 3 The mass content is 38%, comprises the following steps:

[0073] (1) drying and crushing after washing the Bayer red mud, so that the particle size of the broken Bayer red mud is 70 microns;

[0074] (2) Mix the crushed Bayer process red mud with the first type of auxiliary agent, the second type of auxiliary agent and the catalytic auxiliary agent to make the mixture raw meal,

[0075] Wherein, the first type of auxiliary agent is a mixture of graphite, coke and anthracite (the mass ratio of the three substances is 4:2:4), including 80% of the first type of auxiliary agent with a particle size of 100 microns and 20% of the first type of additives with a particle size of 3 microns, the amount of the first type of additives is 1.1 times the theoretical carbon content required after all the iron oxide in the Bayer process red mud is reduced,

[0076] The second type of auxiliary agent is a mixture of sodium hydroxi...

Embodiment 3

[0086] In this example, Fe in the Bayer process red mud 2 o 3 The mass content is 58%, comprises the following steps:

[0087] (1) drying and crushing after washing the Bayer red mud, so that the particle size of the broken Bayer red mud is 40 microns;

[0088] (2) Mix the crushed Bayer process red mud with the first type of auxiliary agent, the second type of auxiliary agent and the catalytic auxiliary agent to make the mixture raw meal,

[0089]Among them, the first type of auxiliary agent is a mixture of graphite, lignite and returned sintered material (the mass ratio of the three substances is 3:5:2), including 75% of the first type of auxiliary agent with a particle size of 60 microns by weight percentage. additives and 25% of the first type of additives with a particle size of 2 microns, the amount of the first type of additives is 1.6 times the theoretical carbon content required after all the iron oxide in the Bayer process red mud is reduced,

[0090] The second ty...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com