Photosensitive resin composition

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition, can solve problems such as direct discharge, harmful hexavalent chromium ions, and lack of storage stability, and achieve the effect of improving preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0033] Specific examples of desirable component (A) in the present invention are as follows:

[0034] (1) Dichromates, such as: ammonium dichromate, potassium dichromate, sodium dichromate and other dichromates.

[0035] (2) Diazide compounds, such as:

[0036] 4,4'-diazidostilbene-2,2'-disulfonic acid (4,4'-diazidostilbene-2,2'-disulfonic acid), 4,4'-diazidostilbene-2 - Sulfonic acid (4,4'-diazidobenzalacetophenone-2-sulfonic acid), 4,4'-diazidostilbene-α-carboxylic acid (4,4'-diazidostilbene-α-carboxylic acid) and such compounds Alkali metal salts, ammonium salts, organic amine salts and other diazide compounds.

[0037] (3) Diazo resins, such as:

[0038] P-diazodiphenylamine or 4-diazo-3-methoxydiphenylamine and 4,4'-bis(methoxymethyl)bis Diazo resin of anion complex of sulfate, phosphate and zinc chloride double salt of polymer of phenyl ether (4,4'-bis-methoxymethyl-diphenyl ether);

[0039]Diazo resins of anionic complexes of sulfate, phosphate and zinc chloride do...

Embodiment 1

[0089]20 g of polyvinyl acetate with an average degree of polymerization of 1000 and an alcoholysis degree of 88% was heated and dissolved in 80 g of water and then cooled to room temperature. Add 8 g of a 10% aqueous solution of diazo resin (diphenylamine 4-diazonium salt and paraformaldehyde condensate) and 5 g of a 10% aqueous solution of 2,2,6,6-tetramethylpiperidinyloxy radical to prepare a photosensitive Resin composition.

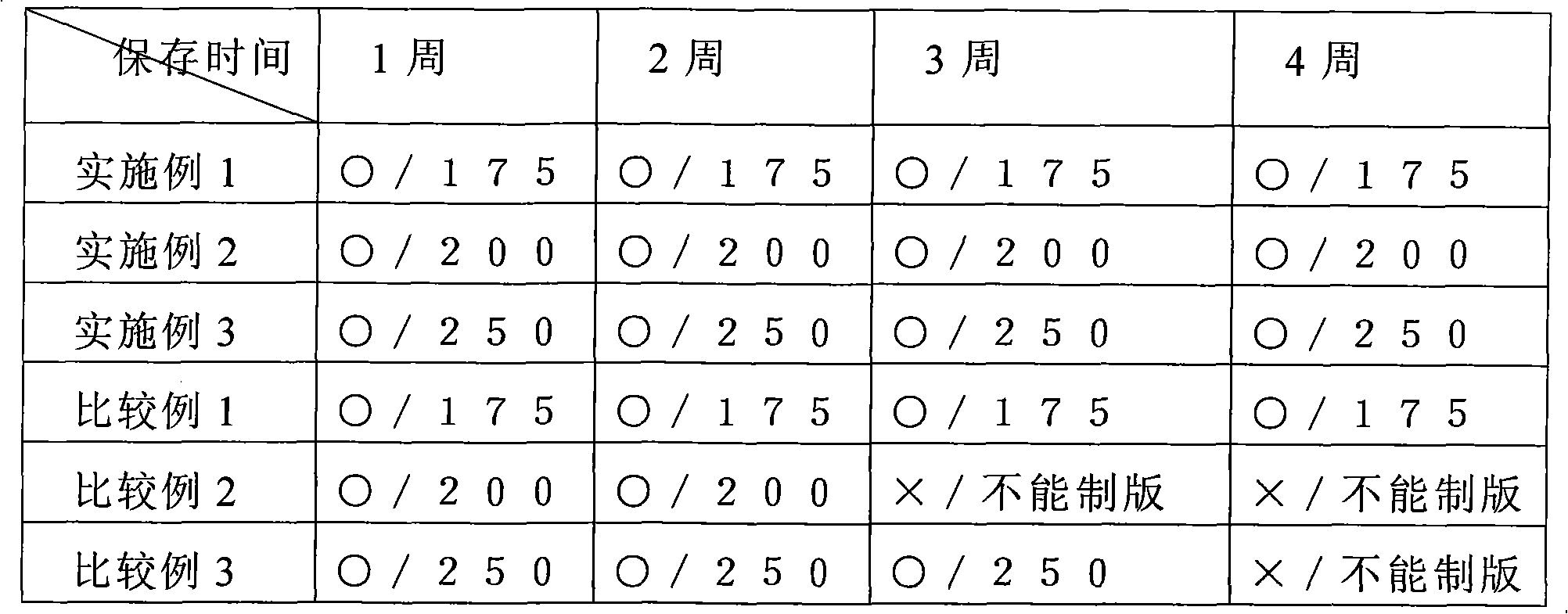

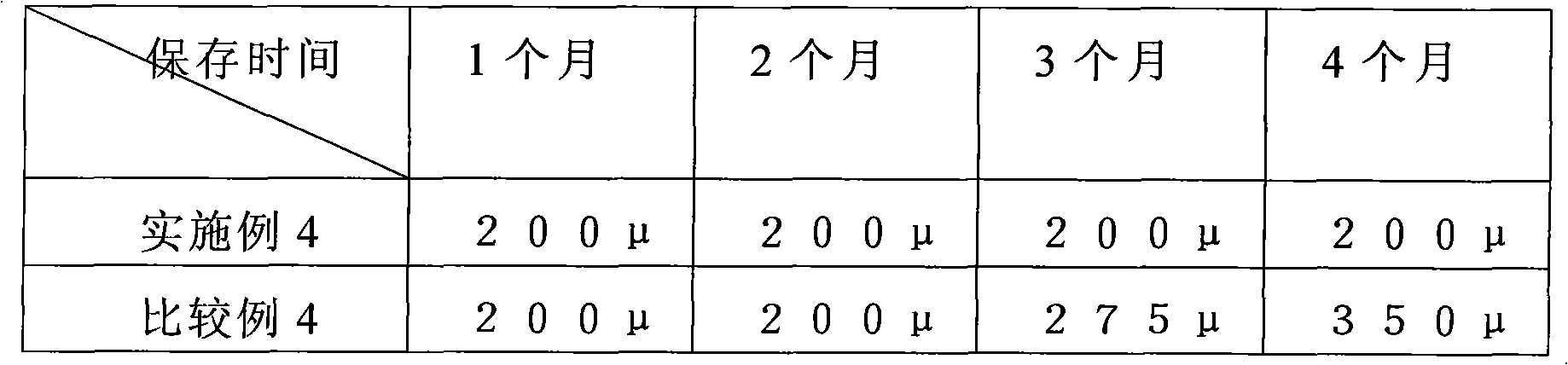

[0090] Test the liquid stability and plate making test of the prepared photosensitive resin composition according to the following methods. The results obtained are recorded in Table 1.

[0091] Plate making test

[0092] Filter the prepared photosensitive resin composition with a 250-mesh polyester fiber mesh, and then use a stainless steel scraper to coat it on the screen plate of an aluminum mesh frame that has been stretched with a 300-mesh polyester mesh, and dry. Then, the coating and drying operations were repeated until the thickness of ...

Embodiment 2

[0097] 20 g of polyvinyl acetate with an average degree of polymerization of 1000 and an alcoholysis degree of 88% was dissolved in 80 g of water in the same manner as in Example 1. Then, while stirring, add 20 g of trimethylolpropane triacrylate in which 0.7 g of a mixture of 1-hydroxycyclohexyl benzophenone and benzophenone and 0.1 g of p-methoxyphenol have been dissolved as the photoinitiator of radical polymerization. and fully emulsified. In this emulsion, 9.6 g of a 10% aqueous solution of diazo resin (diphenylamine-4-diazonium salt and paraformaldehyde condensate) and 10% of 2,2,6,6-tetramethylpiperidinyloxy radical were added. An aqueous solution of 6.5 g was prepared as a photosensitive resin composition.

[0098] The prepared photosensitive resin composition was tested in the same manner as in Example 1, and the results obtained are recorded in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com