Preparation method of lithium-ion battery anode material with oxide coated on surface

A lithium-ion battery, surface coating technology, applied to battery electrodes, circuits, electrical components, etc., can solve problems such as poor safety, unguaranteed product consistency, unfavorable cost performance of lithium-ion batteries, etc., to achieve cycle performance and safety The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

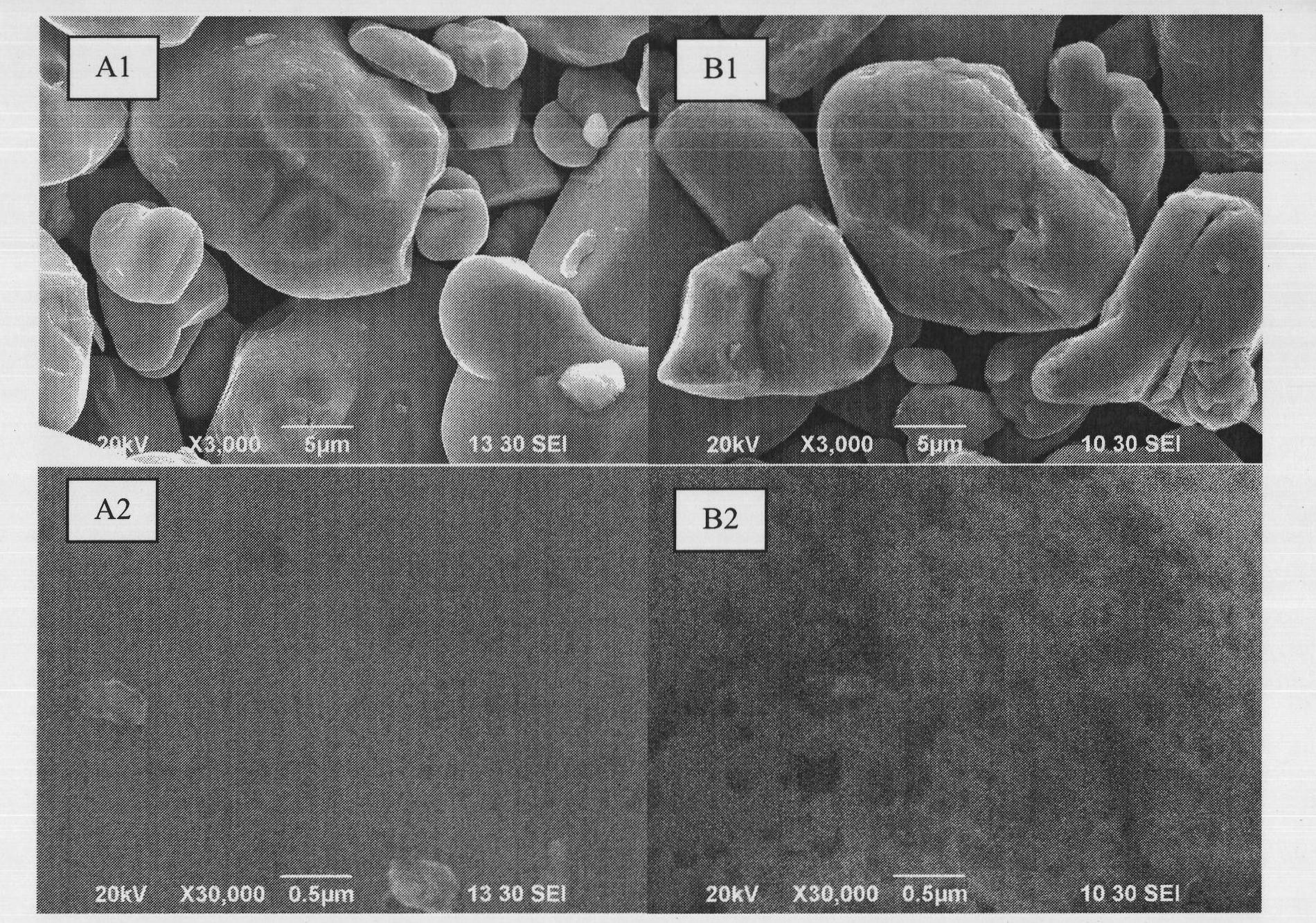

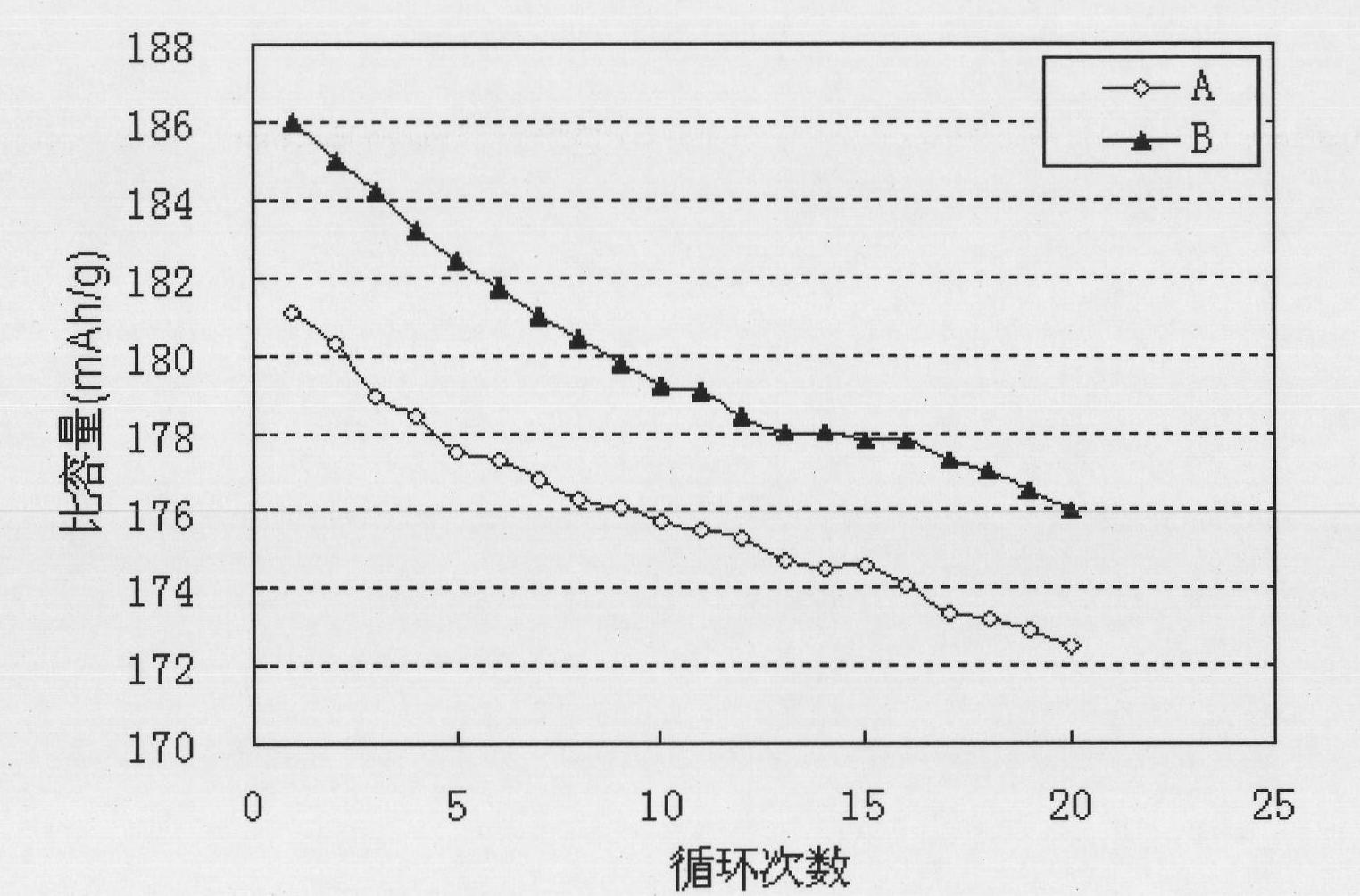

[0038] At 25°C, weigh 1.28g NH 4 HCO 3 , add 500ml of water and stir to dissolve to form a solution; weigh 1.31g of AlCl 3 ·6H 2 O was added to the above solution and stirred for 5 minutes to form a transparent sol; 100g LiCoO 2 Add the powder into the sol, stir evenly, raise the temperature to 60°C and react at 60°C for 4 hours, let stand, remove the supernatant to obtain the sediment; dry the obtained sediment at 80°C, and then in Calcined at 800°C for 4 hours to obtain Al 2 o 3 The coating amount is 0.5% of the positive electrode material.

[0039] The surface coating Al prepared according to the aforementioned preparation method 2 o 3 LiCoO 2 The positive electrode material is uniformly mixed with conductive carbon and polyvinylidene fluoride (PVDF) to make a positive electrode slurry, and coated on the positive electrode current collector to form a positive electrode. With a lithium sheet as the negative electrode, a button battery is formed in a glove box for ele...

Embodiment 2

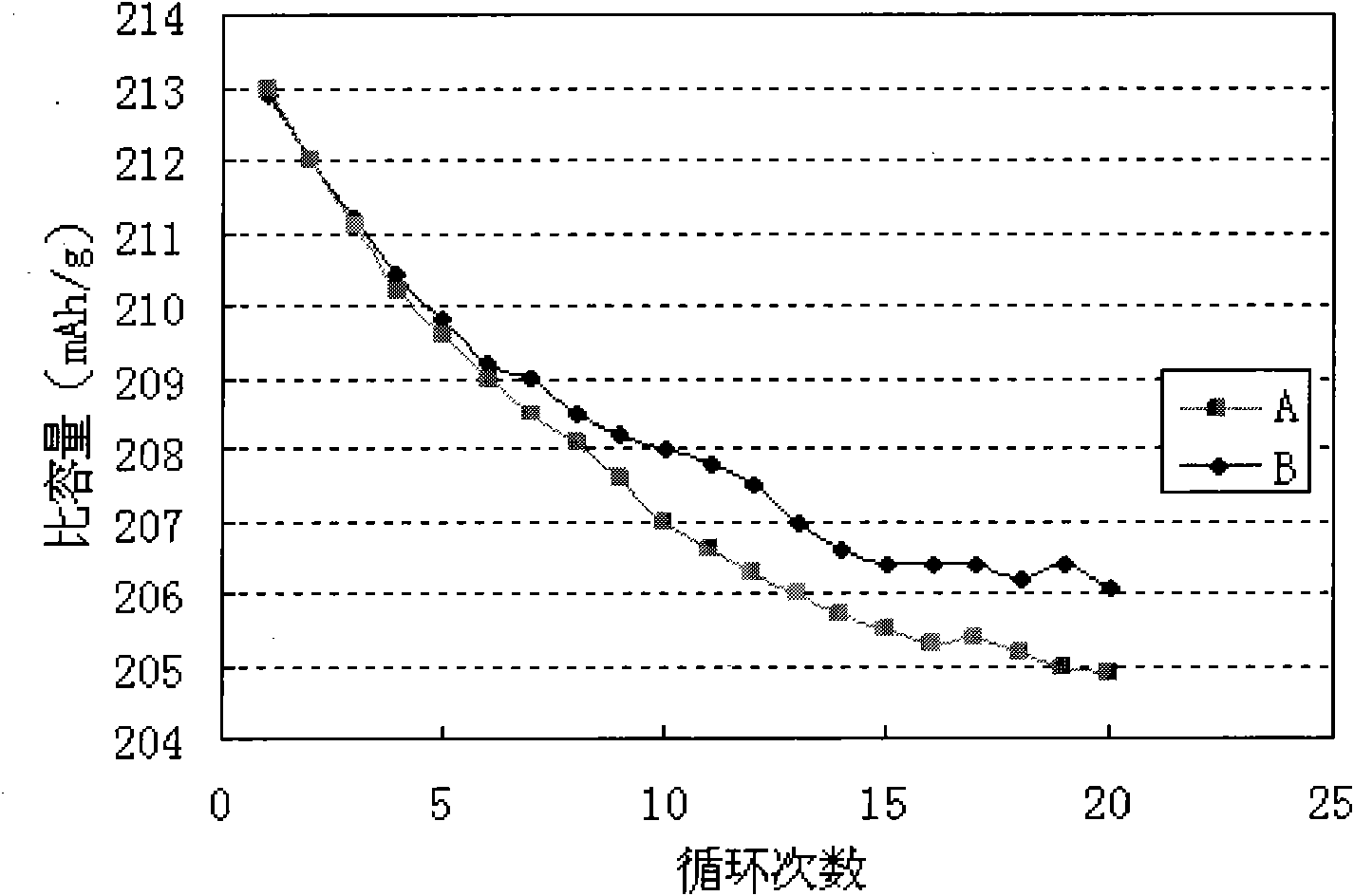

[0041] At 25°C, weigh 1.63g NaHCO 3 , add in the mixture of 300ml water and acetone (volume ratio is 1: 1) and stir to make it dissolve, form solution; Weigh 3g TiOSO 4 ·8H 2 O was added to the above solution and stirred for 15 minutes to form a transparent sol; 100g LiNi 0.5 co 0.2 mn 0.3 o 2 Add the powder into the sol, stir evenly, raise the temperature to 35°C and react at 35°C for 4 hours, let stand, remove the supernatant to obtain the sediment; dry the obtained sediment at 70°C, and then in Calcined at 500°C for 3 hours to obtain TiO 2 The coating amount is 0.8% of the positive electrode material.

[0042] The surface-coated TiO prepared according to the aforementioned preparation method 2 LiNi 0.5 co 0.2 mn 0.3 o 2 The positive electrode material is uniformly mixed with conductive carbon and polyvinylidene fluoride (PVDF) to make a positive electrode slurry, and coated on the positive electrode current collector to form a positive electrode. With a lithium s...

Embodiment 3

[0044] At 25°C, weigh 0.97g NaOH, add it into 200ml ethanol and stir to dissolve it to form a solution; weigh 3.48g Zr(NO 3 ) 4 ·5H 2 O was added to the above solution and stirred for 10 minutes to form a transparent sol; 100g LiNi 0.8 co 0.2 o 2 Add the powder into the sol, stir evenly, raise the temperature to 40°C and react at 40°C for 2 hours, let stand, remove the supernatant to obtain the sediment; dry the obtained sediment at 80°C, and then in Calcined at 400°C for 3 hours to obtain ZrO 2 The coating amount is 1% positive electrode material.

[0045] The surface-coated ZrO prepared according to the aforementioned preparation method 2 LiNi 0.8 co 0.2 o 2 The positive electrode material is uniformly mixed with conductive carbon and polyvinylidene fluoride (PVDF) to make a positive electrode slurry, and coated on the positive electrode current collector to form a positive electrode. With a lithium sheet as the negative electrode, a button battery is formed in a gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com