Method for preparing absorbent resin

A water-absorbing resin and water-absorbing technology, which can be used in fire protection equipment and other directions, can solve problems such as the inability to meet the requirements of high temperature thermal stability coal seam adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

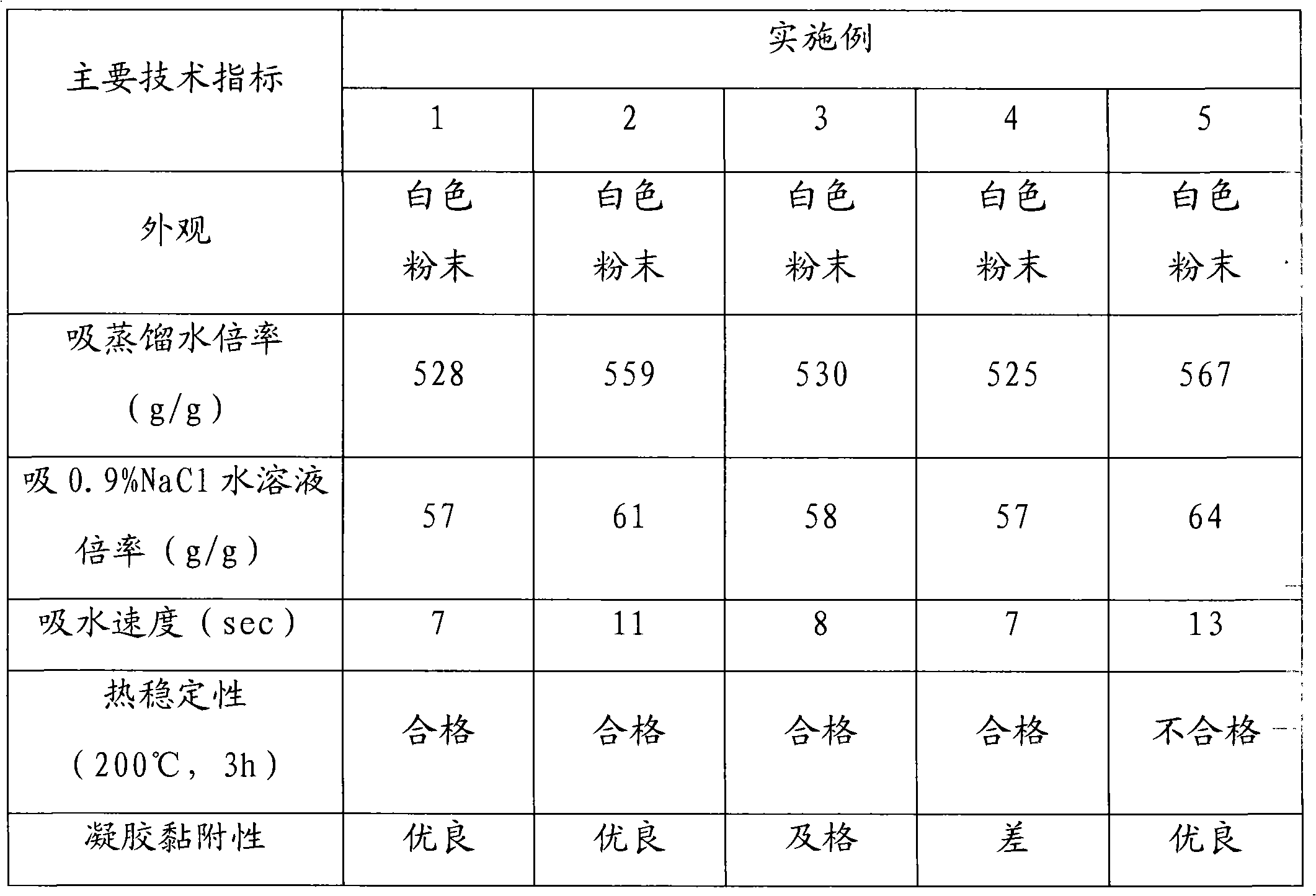

Examples

preparation example Construction

[0014] The preparation method of the super absorbent resin for coal mine fire prevention and fire extinguishing according to the present invention includes the following preparation steps:

[0015] In the first step, three vinyl monomers of acrylic acid, acrylamide and methylol acrylamide are first mixed in water, and then trimethylol propyl acrylate primary crosslinking agent is mixed in water to form a mixed reaction system. Among them, acrylic acid, acrylamide, and methylol acrylamide account for 60-90%, 39-9%, and 20-1% of the total mass of the three vinyl monomers, respectively. The amount of trimethylol propyl acrylate is 0.01-0.1% of the total mass of the three ethylene monomers; then, neutralize with sodium hydroxide to adjust the acid value of the reaction system, use peroxide to initiate the polymerization reaction, that is, add a radical polymerization initiator A free radical quaternary copolymerization reaction occurs, the temperature of the polymerization reaction i...

Embodiment 1

[0022] In a 1000ml three-necked flask with stirring, a thermometer, and a dropping funnel containing a 42% concentration of 200g sodium hydroxide solution, add 100ml of distilled water, turn on the stirring, and then slowly pour 200ml of acrylic acid, 60g of acrylamide, 10 Grams of methylol acrylamide and 0.02 grams of trimethylol propyl acrylate, stir to dissolve, add 0.81 grams of sodium persulfate, pour the mixture into a stainless steel pan, and then put it in an oven for polymerization to control the polymerization The temperature is 50-100°C, the polymerization reaction time is 2-4 hours, and finally a gel product is obtained.

[0023] The gel product is cut, dried, crushed, and sieved to obtain a preliminary water-absorbent resin product; the preliminary water-absorbent resin product is subjected to secondary crosslinking treatment with epichlorohydrin to obtain a water-absorbent resin product.

Embodiment 2

[0025] In a 1000ml three-necked flask with stirring, a thermometer, and a dropping funnel containing a 42% concentration of 200g sodium hydroxide solution, add 100ml of distilled water, turn on the stirring, and then slowly pour 200ml of acrylic acid, 40g of acrylamide, 10 Grams of methylol acrylamide and 0.02 grams of trimethylol propyl acrylate, stir to dissolve, add 0.70 grams of sodium persulfate, pour the mixture into a stainless steel pan, and then put it in an oven for polymerization reaction, control the polymerization The temperature is 50-100°C, the polymerization reaction time is 2-4 hours, and finally a gel product is obtained.

[0026] The gel product is cut, dried, crushed, and sieved to obtain a preliminary water-absorbent resin product; the preliminary water-absorbent resin product is subjected to secondary crosslinking treatment with epichlorohydrin to obtain a water-absorbent resin product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com