Manufacturing method of granular iron oxide black pigment and double-roller grinder for realizing same

A technology of iron oxide black and manufacturing method, which is applied in fibrous filler, grain treatment, dyeing physical treatment, etc., can solve the problems of increased energy consumption, decreased coloring strength, and affecting the performance of color tone, etc., and achieves low production cost, The mechanical hardness of the particles is moderate, which is convenient for the effect of material pipeline transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

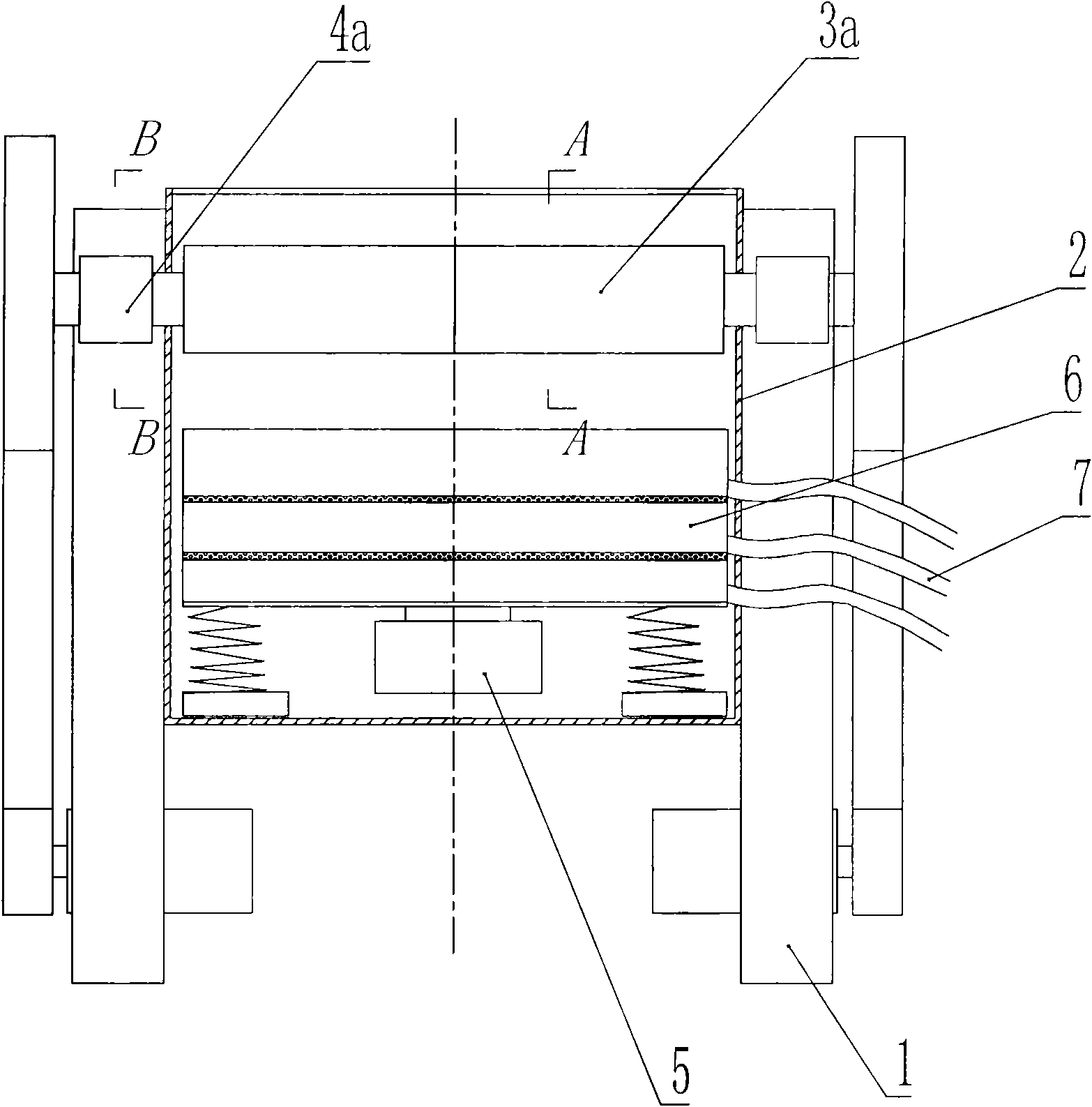

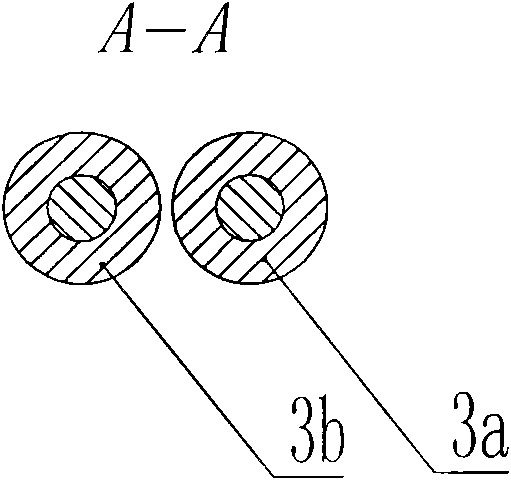

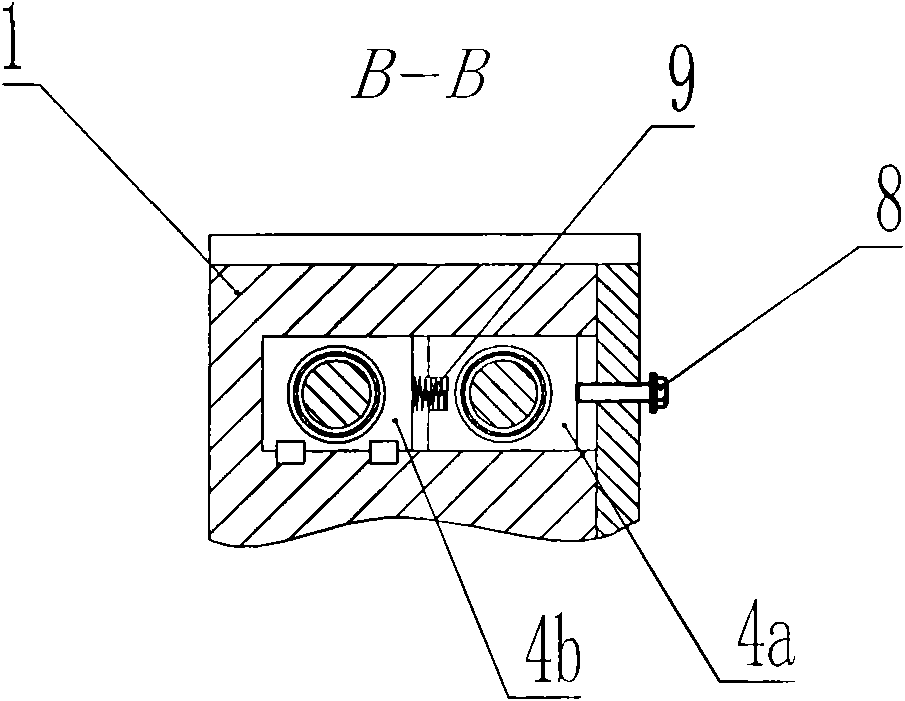

Method used

Image

Examples

Embodiment 1

[0029] Put 1,000 kg of iron black 330 block dry material produced by our company into the feeding bin, then pass the conveying screw at a speed of 15 rpm and a motor power of 3KW, and add the material to the counter roller with a speed of 30 rpm and a motor power of 7.5KW Pulverizer, crush it into the required particle size, and then pass through the two-stage rotary vibrating screen, first pass through the 20-mesh sieve, and then pass through the 80-mesh sieve for classification, the particles between 20-80 mesh in the middle section That is the finished product. The particles larger than 20 mesh, that is, 840 microns are returned to the roller mill for crushing and recycling, and the fine particles smaller than 80 mesh, that is, 180 microns, are pulverized by a vortex mill and sold as powdered iron oxide black pigments. Granular iron oxide black KS330G of the present invention is compared with powdered similar products as shown in the following table:

[0030] samp...

Embodiment 2

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com